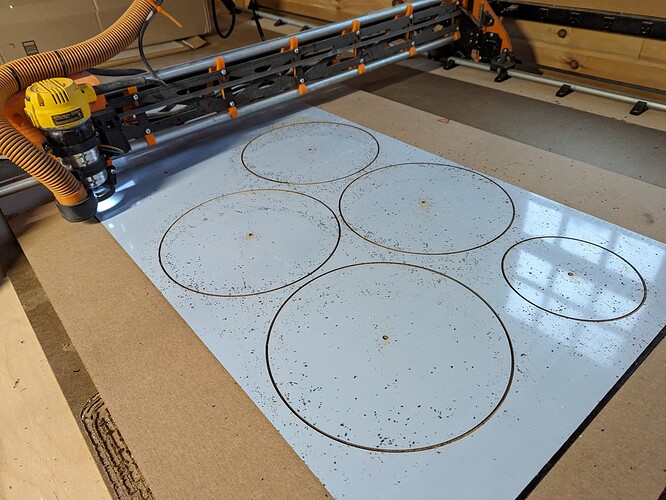

This is more of a use case than a full project. I built a record lathe for one of my sons for Christmas, and learned in my research that the Lexan discs used as recording media cost $10 each. I was able to find 2 X 4’ sheets of 0.060" black Lexan for about $25 each online (though shipping was a bit spendy) and today my Lowrider made short work of cutting a bunch of 7" and 12" blanks.

Might be a good little etsy side hustle?

Awesome! Have you got any photos of the record lathe?

@vicious1, talk about a niche, right? ![]()

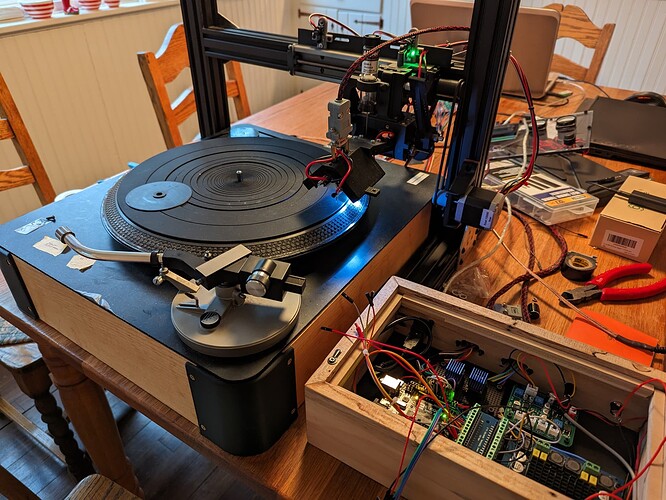

Whoa! That is way more of a set up than I ever imagined!

I would have expected a record to explode trying to cut it with a router, or anything really.

Neat!

The method they use to make the masters is pretty neat.

It really is. This lathe will “emboss” Lexan discs using a sapphire stylus, but the process of actually cutting vinyl or lacquer with a diamond, then plating it with metal and pressing copies is fascinating. Every time I turn around, I fall into different rabbit hole…

I just hope you can cut it in one pass. It would be hard to get the band to play it the same the second time.

Nice work!

I’ve been developing a mono cutting head based on the Presto 1-D… I’ve got 5-6 together so far, I’m hoping to get the manuals and packaging finished over Christmas!

What are you using for the pitch control? My lathes run from the accelstepper library, but I’m looking at changing it all over to ad9833 frequency generators.

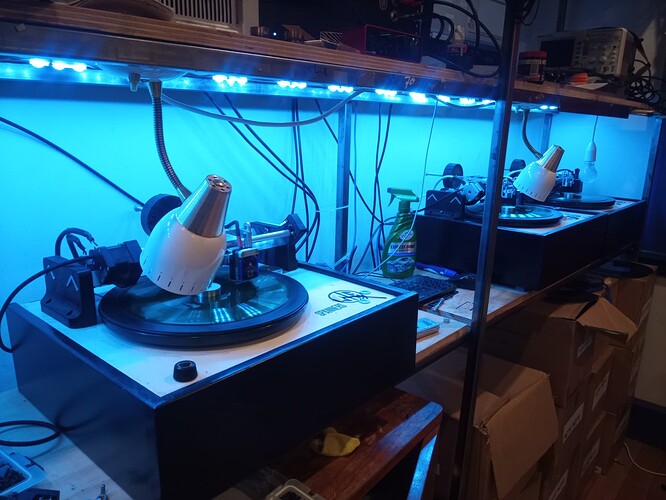

The whole process can be a bit of nightmare, I’m running 3 lathes and have just spent the day reconfiguring them all! It seems there’s always a ‘bad’ one and one you fix that the other two become the bad ones, rinse and repeat, pull your hair out…

I’ve been making my own stylus too - might be a nice next step for you

I make mine from 0.5mm tool tungsten and 1.6mm aluminium welding rods…

These are 3 of my machines, there a prototype as well, along with one that was intended for cutting with diamond

Jeffe, funny you mention that. My boys are all musicians, and I was thinking of trying to do an old-school live-to-disc recording when they’re home for the holidays.

Wow! That setup puts mine to shame. Nice work! I had been using an Arduino with a stepper motor and TMC2209 stick from my old Lowrider 2 for the turntable. The speed control was good, but I haven’t been able to isolate the motor enough to eliminate noise in the recording, so since I’m pressed for time I just punted and ordered a commercially available direct drive turntable.

I’ve been playing with the 2209 + steppers for playback turntables, they can be a bit noisy, but I haven’t managed to make a decent isolation mount for it.

The lathes run Leadshine Integrated Steppers, driven by ad9833’s and they’re pretty noiseless out of the box, I originally used an JMC iHSS57 - which was much noisier, but it does have useable serial programming software which you can use to tune the noise out.

The decoupling I use for the servos are pads made from acrylic paint mixed with acetic cure silicone, they work as pads and the motor gets clamped to the underside of the plinth…

I’m hoping to try see if I can direct drive a playback platter with a UART Controlled TMC2209 and stepper over christmas, another option is a BLDC driven with a SimpleFOC driver - I’ve read they can also run stepper motors themselves, but I can’t find anything out about the vibration or noise output…