I built an original MPCNC 10+ years ago using the 3d printer I had. Then re-built it with Burly parts. Then built a LR.

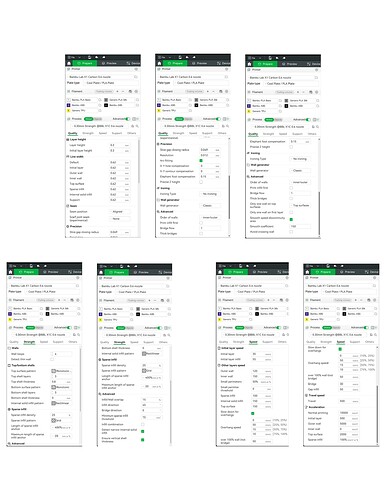

Got a Bambu last fall, and was so excited I printed a Primo out of old PLA I had lying around and it worked pretty well! Didn’t pay much attention to the recommended infill or walls. I just ran off half-cocked and rebuilt the machine.

Upgraded to the Jackpot, which is better than Marlin in pretty much every way.

Got it all dialed in, making very accurate cuts at reasonable speeds.

But then started doing some things that require deep travel on the Z axis through some pretty dense wood. It was already a tall machine, and I made it taller.

Gotta get stiffer.

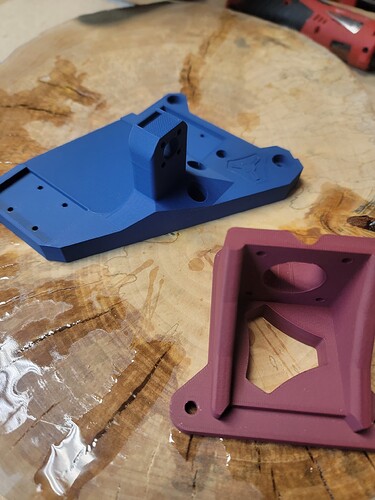

I tried some PETG-CF and some PAHT-CF. Very stiff, but a bit stringy and difficult to print. Found myself drilling out pretty much every hole. Nothing fit the hardware on the first try.

I must say, PLA-CF is awesome. It’s not terribly expensive, prints easily, and man, is it accurate.

The Primo has lots of horizontal holes and nut traps. With the PLA-CF, everything fits perfectly. Some of the parts ought to be tightened hard, and you can do that. The nuts fit perfectly and the plastic doesn’t deform.

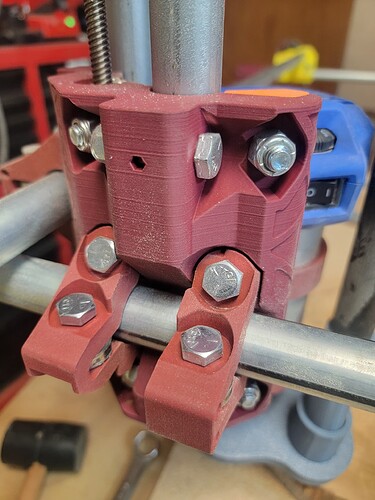

Started with the core, then the core clamps. Today I replaced all of the corners. Next, the feet (with a custom design). Every part I’ve replaced with PLA-CF has made the machine noticeably quieter at high speed, less fiddly, and more accurate at the deeper plunge I need.

It’s been a downright joy to assemble.

Highly recommended.