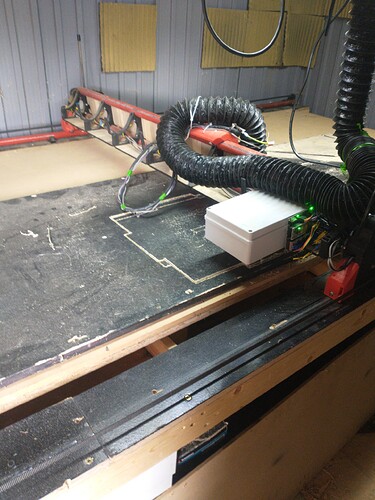

So I rebuilt my table again. The bearings on the non rail side were wearing a groove in the crappy pine. I expected that, but not quite so quickly! Moved the “struts” from the original MVP frame to within the pallet so the 12mm MDF I’m using as a spoilboard sits directly on the 18mm OSB tabletop rather than sagging slightly between the spans of lumber. Should have done that in the first place, really. And added strips of lacquered plywood to the rail sides, though there’s an annoying join because the piece was about 7ft.

In doing so I noticed my surface is positioned to far toward Ymax to actually be able to usefully reach a full 8ft. To do anything about that I’d need to strip the table down again, and I really don’t feel like it right now…

Speaking of which, is there a good guide for getting the rails and Y belts positioned relative to the board? I still feel like I’m essentially stabbing in the dark when doing so (as a result, my squaring is still pretty abysmal) - probably just missed something obvious!

Also still really struggling to find feeds that are quick enough not to cook bits, but slow enough to not skip steps on my mysteriously underpowered machine. On that particular cut in the picture it seems to consistently skip on what is the top left corner, so X moving towards the centre of the beam. Seems worse that way than coming back, but that could just as easily be positional. That then causes Y to struggle since it’s out of position and trying to cut way too deep. Considering throwing one of the 60mm overkill motors I have onto X, since it seems doable (unlike Y) and if it still skips then I know something really odd is going on, right?  Wondering about my belt tension being way off - they’re super slack. I did do a “test square” that came out nearly dead on dimensionally, though. So probably not that.

Wondering about my belt tension being way off - they’re super slack. I did do a “test square” that came out nearly dead on dimensionally, though. So probably not that.

I’m also still struggling to ‘level’ such a large table – honestly I’d cut the machine down to a much smaller size in a heartbeat if it hadn’t already become clear I do actually use the 8x4 working area, it is not just for bragging rights. It’s nowhere close to “true level” (blame the idiot that laid the shed base  ) but the machine and spoil board appear relatively level in respect to one another. Yet running a cut it becomes obvious that they still aren’t, though. Strange, and enough of a pain that I’m wondering about making the machine smaller anyway and using fixtures for bigger parts, even though that’s most of them…

) but the machine and spoil board appear relatively level in respect to one another. Yet running a cut it becomes obvious that they still aren’t, though. Strange, and enough of a pain that I’m wondering about making the machine smaller anyway and using fixtures for bigger parts, even though that’s most of them…

Need to cut new strut plates, too. I know mine don’t look temporary, but what you sneakily don’t see in my (terrible) photos is that the laser I can use is only A0, so they’re each in two parts. Figured it was better than the 3d printed temp struts, but presumably still far worse than one piece struts. I was about to do it in some MDF I had to hand, but it turns out it’s 8mm. So should I use:

- 6mm MDF (would have to buy it, and given how much material I have stashed that feels a bit silly)

- 6mm Ply (to hand)

- 5mm acrylic (to hand, but “feels way more wobbly” than ply or mdf. Maybe only in dimensions we don’t care about?)

- ~5mm alu (can acquire for scrap price but really doubt the current state of my machine is up to any metal)

I also need to work on the routing of my hose, manual intervention is occasionally required at the moment, but it’s nice to not be absolutely drowning in dust! I also did jury rig myself up a touchplate from scrap bits, though. Way better than eyeballing it.

Lots of learning, lots of me shooting myself into the foot by half arsing stuff… That jackpot really needs a case…

Was thinking I would love to build a MP3DPv5 once this gets dialled in, but given how much I’ve struggled to build the “easy” machine I think I’d best not…

![]()