Hello! Thank you for the reply.

I use the Inline commands in Lightburn and a small gcode looks like the one attached.

; LightBurn 1.0.04

; Marlin device profile, current position

; Bounds: X0 Y0 to X59 Y52

G21

G91

; Cut @ 500 mm/min, 50% power

M9

M05

G0X0 Y0 F0

; Layer C00

G1 Y52 F500 I S127.5

G1X59

G1 Y-52

G1X-59

M9

M05 P1

; return to starting pos

G0 X0 Y0 F0

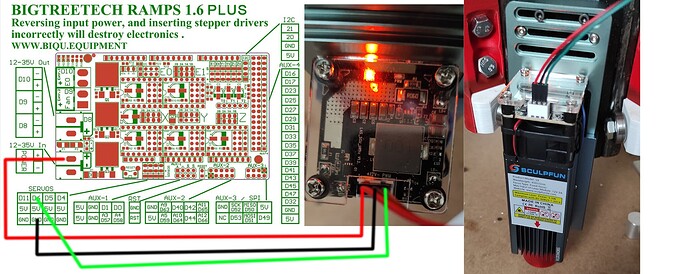

I’m wandering if my connections to the board are good.