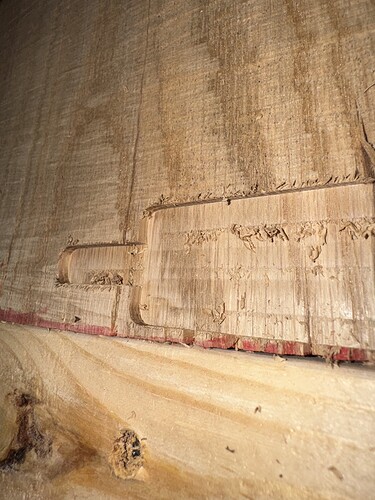

Is it dry? I don’t have experience milling green wood but it definitely turns differently. If you are getting very small chips or sawdust I would believe those would clog up the bit much more than if it were dry.

what did you say about my bits ![]()

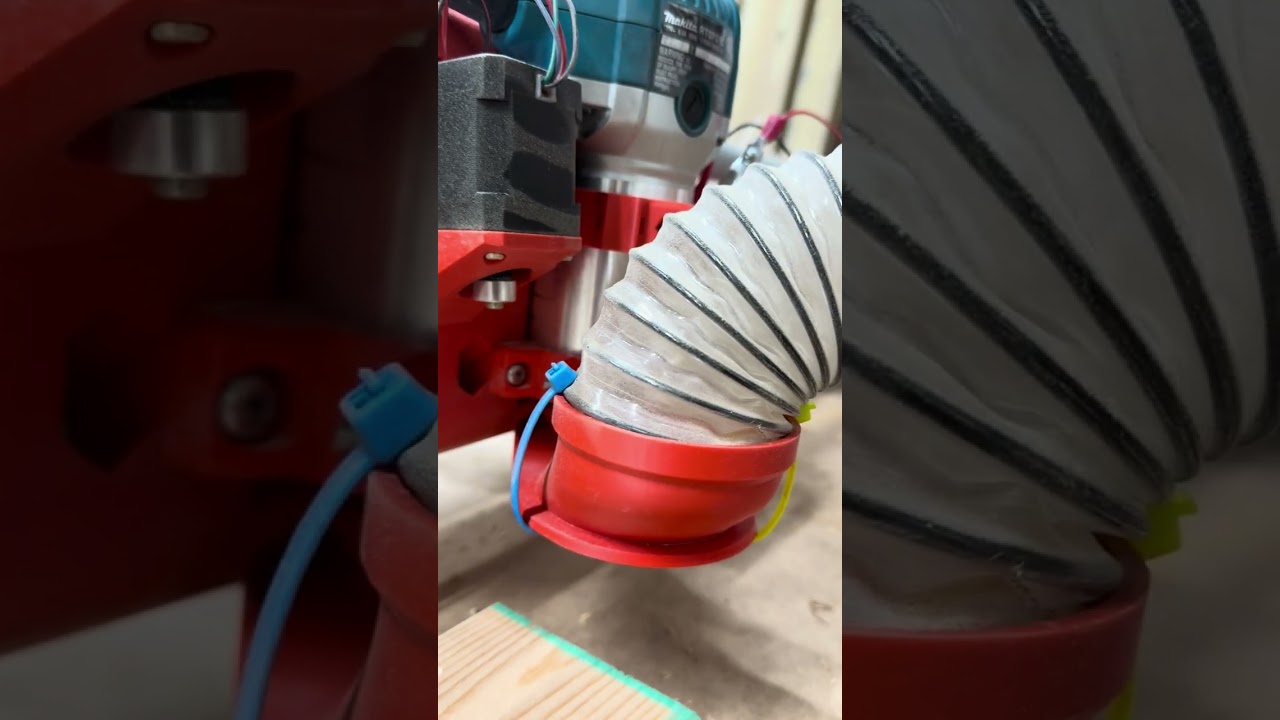

I’m very interested in learning more about the settings on the control board config stuff later!

Ok so I have a successful line at 100 inches/min at 2mm DOC… and I hate to say it but I think Jonathan was the winner here because the new bit went through it like butter, don’t mind me messing around in the video when it was going at 2mm it was great, then I tried 3 and it said NO

It is dry enough for chips, but 10% compared to 5% equilibrium for my area.

It just shouldn’t say no…

that’s my question in the start, why does it just stop instead of doing something else. I feel like I have something loose or off in general.

It’s a mystery. ![]()

Is it just stopping or is it sitting there skipping steps and you just cant hear it over the router?

are your grub screws on the motor pullies tight and locktite applied??

Whenever doing just normal move operations and not an actual job/program, check you acceleration settings. I found mine we’re really high, which causes the bit to move super fast right from the get go to get it up to the requested speed.

We’re all talking about unexpected X motion stop at 0:32 in the video? Manually jogging 100mm long X, but it halts before full speed reached (maybe slow acceleration like others suggested), or, are you using some gcode script worth eyeballing?

Already checked belt isn’t overly tensioned? Don’t want sloppy loose belt, but, you also don’t want super tight belt tension adding to motion friction/resistance that’d lower overall force that can overpower the steppers cause then to skip steps or completely halt.

Is this just an X thing? Do you see same behavior in Y axis? Are you doing a surfacing job that would perform better doing bulk of the cuts along Y axis instead of X?

The microcontroller doesn’t have any idea where the motors are or how hard the bit is pushing back. If a loose pulley or skipped step caused that, the rest of the pattern would be off by the amount it skipped.

It looks to me more like a software or gcode sending bug. Like something isn’t communicating properly and it missed a reaponse until it timed out. But that is based on the assumptions:

- I didn’t hear any skipped steps.

- It looked like it was going the right way after the pause.

Ok new information, this bit is sharp enough to make cuts at 40 inches/min but it stoped here again on 100 inches/min for no reason that I can see this time

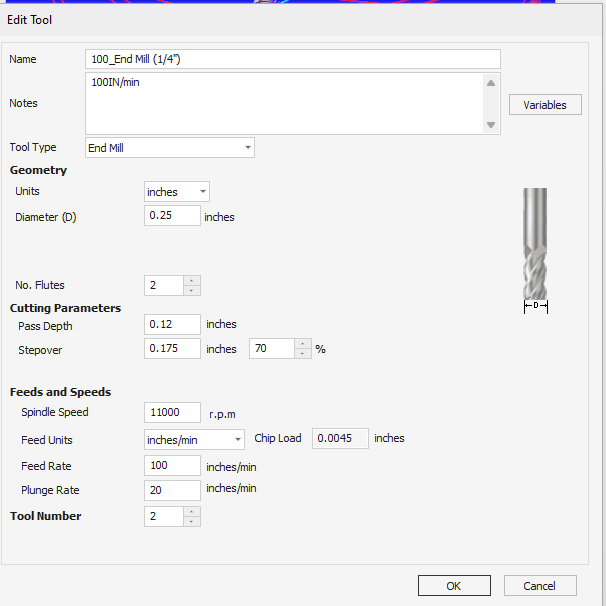

Here are the settings, I even tried lower DOC

The jackpot board is from 2/2024, so this year at least.

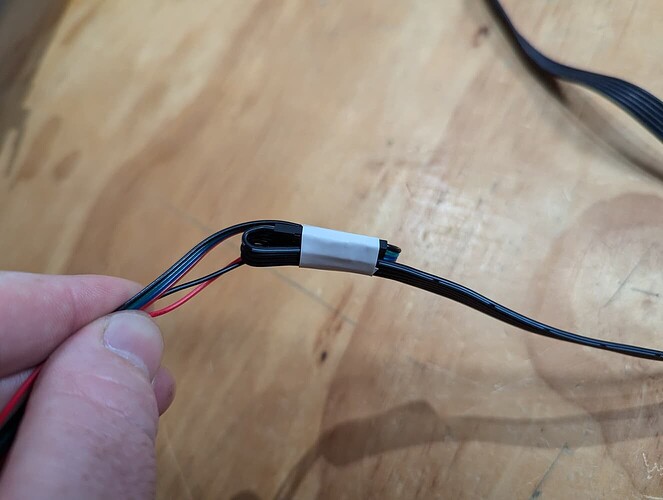

I had a similar issue, X axis stuttering, jamming in a couple of different locations. I finally tracked it down to a loose connection at the X motor wire where it connected to the extension cable. Movement of the cable bundle during X moves was causing an intermittent problem, just at a few different locations.

Wow that’s actually pretty great info there! I’ll check it out, but that sounds exactly like what is happening!

Heat shrink tubing over the connectors will hopefully hold them together better than tape.

Which version of FluidNC?

3.17.2 or 3.7.12 I’ll check again but those were the numbers

Great to see your LR4 running fast…

Curious what was causing the pesky halting behavior?

I think what Mike said and the thread about twisting. My best guess is that if the bit is even dull at all, the kpgf is too high for the steppers push it through the hardwood at those speeds.