You could move it further from the corner, closer to the spool.

They’re 12v LED pucks designed for boats/walkways. They’re not RGB or anything fancy. Just lighting so I can see what I’m doing. I 3d printed a mount for attaching them to the extrusion.

I used a 12v buck converter to step down the voltage from my 24v power supply.

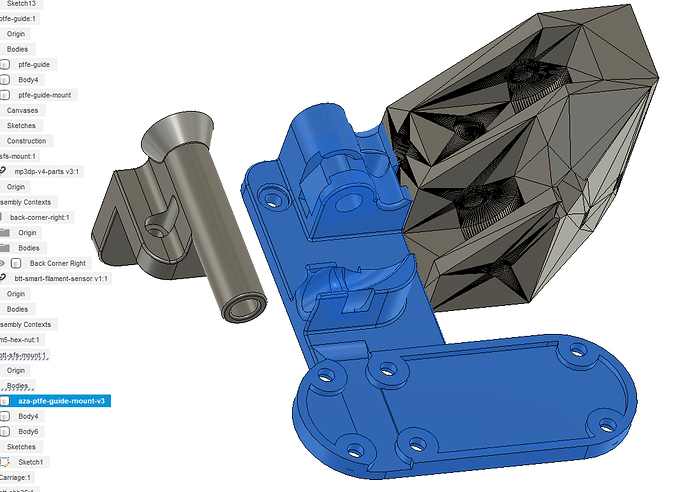

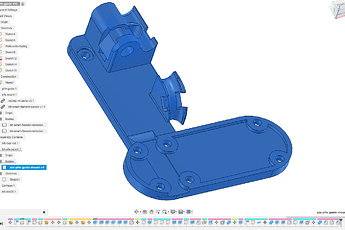

IF you’re going to make a basic PTFE guide, but then allow scope creep for should/nice-to have things like… routing wiring, mounting a motion based runout sensor, including zip tie slots, replacing sensor housing parts to keep a slim profile, etc…

Then, do consider ensuring the basic requirement of PTFE guiding will still work ![]()

v3 render looked great, but failed in reality…

v4 should work better…

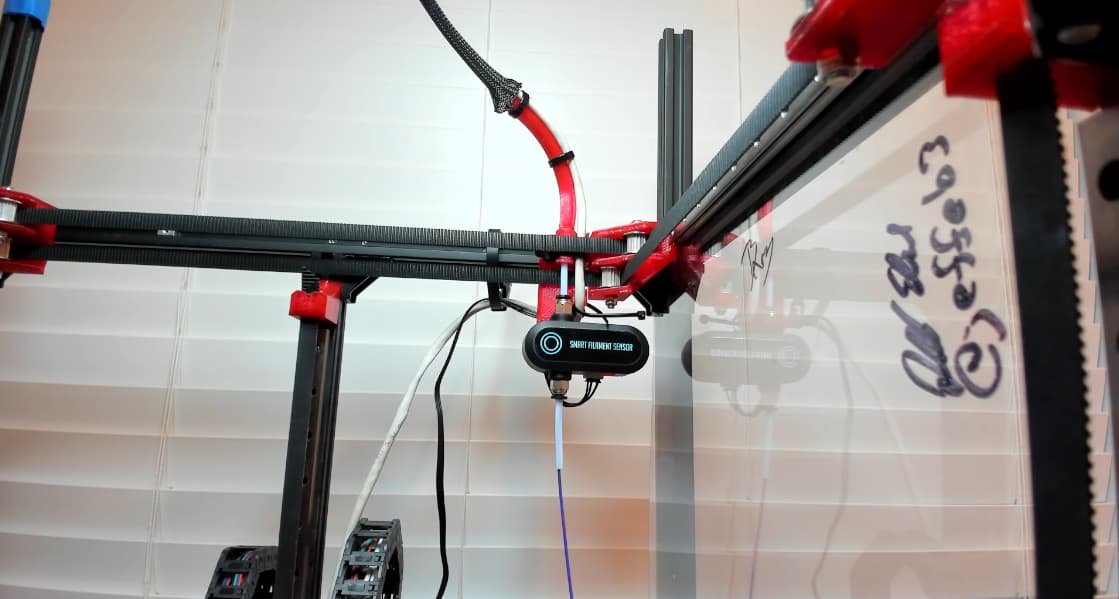

I like this routing for the CAN wire. Mine goes straight down to the base and under so it will be a straight shot.

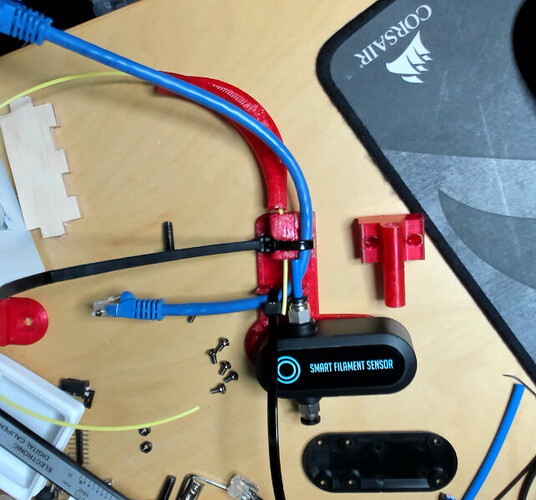

Are you using this as the back cover for the runout sensor?

Thanks Mike, yep, am doubling up the mount as a back cover for the runout sensor. Alternative was to create a clip holder or something. Also included recessed channel within the back cover to help hide and hold/strain-relief runout sensor wiring.

Have interior sheet metal panel that the mount is resting against (will share pic), the panels helped with squaring, but I don’t like how the interior panels restrict being able to easily mod the interior. I guess interior panels would be great if you have a fully considered design that won’t be modified.

Planning to run CAN and Runout wires through new hole in the interior panel, then route CAN and Runout wires along the extrusion down to the base where wiring/controller barely fit under the plate/z-posts. Will update when done… Suggestions appreciated, cheers!

This is where I ended up…

Shared models in my usual V1E mod repo at https://github.com/aaronse/v1engineering-mods/tree/main/mp3dp-v4/mods/filament-guide, and on Printables.

Works, but the straggler CAN and Runout Sensor wires need extending/replacing so they can be routed/mounted neatly along the extrusion to the controller box resting under the bed plate.

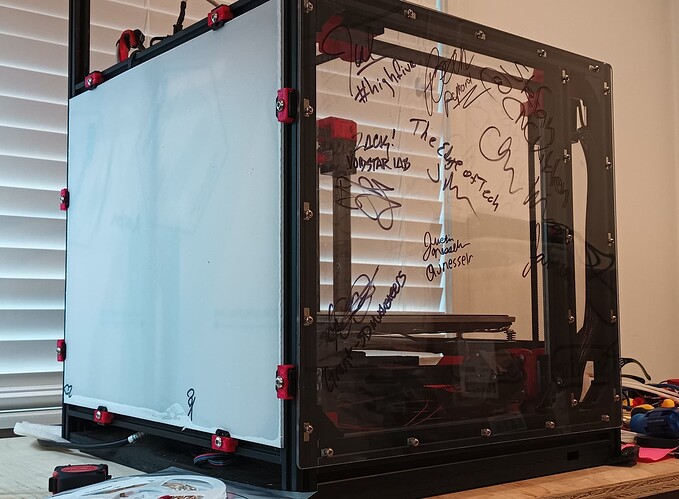

Some guys scribbled on your printer. ![]()

Just noticed my setup ended up with filament spool placement, runout sensor and PTFE routing being similar to Creality Sermoon D3 Pro’s approach. Just stumbled across Sermoon earlier today.