Hello, i built my cnc about a year ago and haven’t gotten around to using it a lot. but today when i went to go cut something on the cnc when i hit start on the program only one of the z axis rapidity moved up witch left the machine out of level. i thought it could be a firmware or power supply issue but after changing the power supply and putting new firmware on the cnc it is still doing it. I’m using the same stepper motor drivers for both Z Axis and they have their steps / mm set correctly. Any help would be greatly appreciated.

Are you sure you don’t have a mechanical issue? It is pretty common for the grub screws on the connector between the stepper motor and the lead screw to come loose. You might also check the lube for the lead screws and to check if either is binding.

If you set the micro-steps manually for your stepper drivers (DRV8825 and A4988), then check to make sure the micro-step jumpers are still seated.

Also swap the wiring for Z1 and Z2 at the control board (with the power off) and run a test to see if the problem stays on the same side or moves to the other side. If it stays on the same side, you likely have a wiring issue.

@robertbu After running your tests the problem moved to the other side. witch i think means that the driver is the problem.

Driver is suspect. The next test would be to swap the stepper drivers Z1 <-> Z2 (power off). If the issue follows the driver, then yes, it is a driver issue. If it does not follow the driver, then you have a control board or firmware or jumper issue.

I had a similar issue with the LR3, which ended up being a firmware problem. The post: Problem with Z motors out of sync - #3 by lsoaresesilva

When i when to use my cnc again i ran into the same problem where one of the Z motors lost 5mm but when i started they where perfectly leveled.

after alot of time spent trying to fix the problem i think i found the problem. one of the z axis stepper motor cables 4 pin connector melted. i think it was caused by a bad stepper motor driver.

A melted connector usually means the connector was loose. The driver was still pushing the same current. But it was arcing across a small gap, which causes more heat.

i fixed the meted connector issue buy just soldering on a new cable with a connector on it. and again when i when to run my test one of the Z motors is 5mm off from the other, when i perfectly leveled the machine to begin with. anyone know why this is happening?

Remember, there are 2 sets of grub screws on the Z axis. One set is on the motor shaft, and the one shoukd be on the flat part of the shaft.

The other is on the threaded rod, and there is no flat spot, unless you file/drill one in. Either set slipping could result in this.

The V1 firmware should never let the pair of motors go out of synch once powered up. You’d have to do something really weird to be able to do that.

i have had the lowrider for 2 years now and not once have i gotten a successful cut on it. i think i will disassemble it and make the lowrider 3. (Edit: nevermind the LR3 can only cut up to 1.5 in thick material.)

@SupraGuy I have checked everything on the machine none of the grub screws are loose and the axes is not binding, could it just be a bad stepper motor?

@Ryan Do you have any ideas why this might be happening?

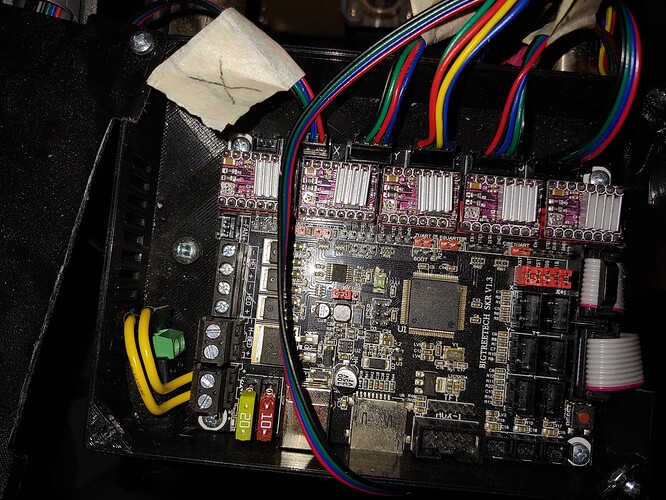

What control board and I need to see a picture of it wired up?

You are also using different screws. Z Problems

Please list everything you have since it is not from here. We are making assumptions based on this hardware and they will not help. We need to know what you have and pictures help more than you can imagine.

i am running a skr1.3 with this

firmware. the lead screws i use are 2mm lead and 2mm pitch.

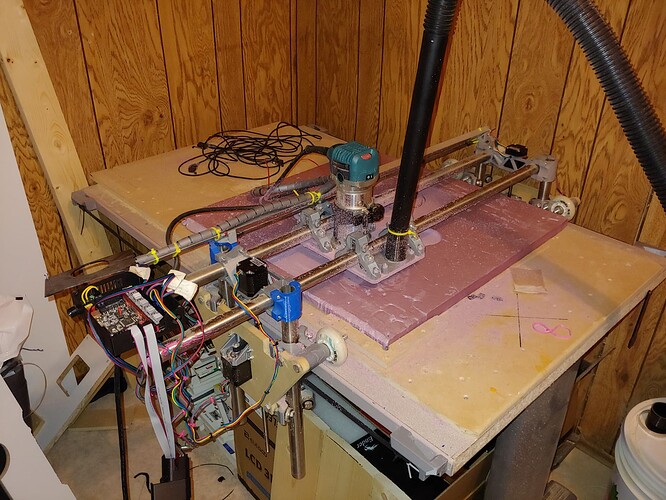

Okay sorry but first thing is that straight piece on your vacuum has to go. That is the biggest accuracy killer we deal with around here and that has to be the largest I have seen. Hook the flexible hose straight to the port.

That firmware is not set up for your Z leadscrews, and those drivers need to be manually tuned with a multimeter on that little digipot, what voltage do you have them set at?

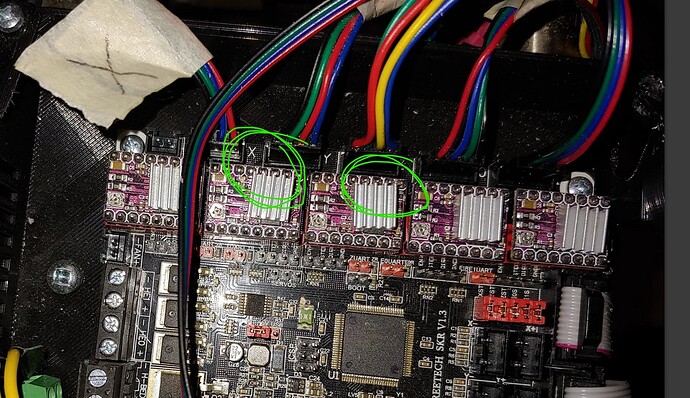

These two heat sinks look like they are really close to the pins. Take a quick look to make sure they are not shorting them.

That is Y and Z1

I have set the voltage on the stepper motor drivers and the heat sinks are not shorting out the drivers I checked. And I have set the steps per mm to the correct amount.