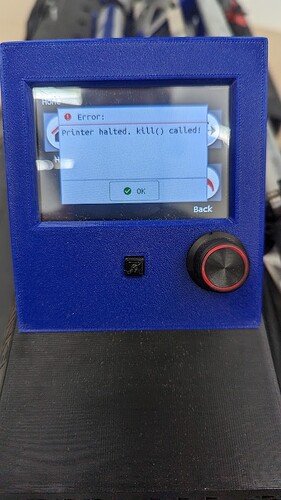

i am going to guess… replacing the board wont necessarily solve my issue correct. seems like it is luck of the draw. i am still within the return period.

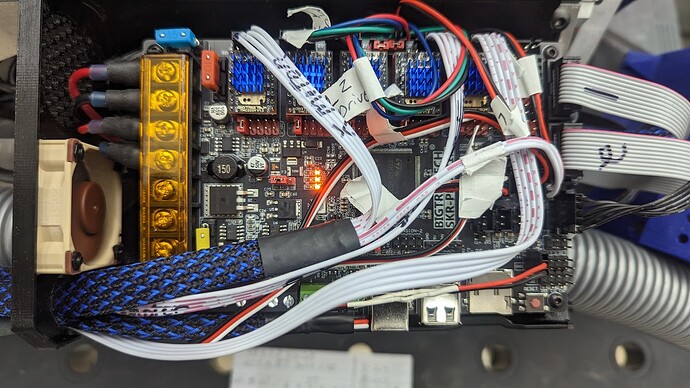

On the forum, we saw several boards with this problem in a short period of time. After that, only an occasional topic that turned out to be this issue. My theory is there is a bad batch of boards, and that occasionally one of those boards ends up on an MPCNC.

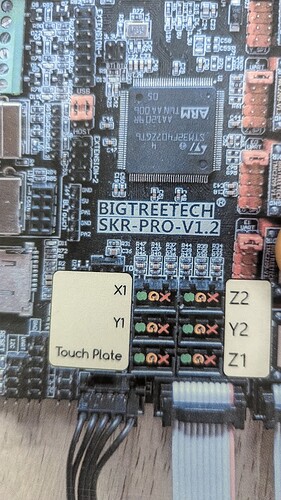

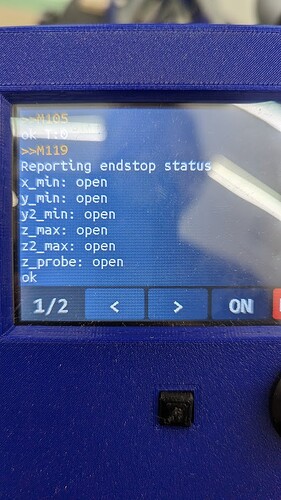

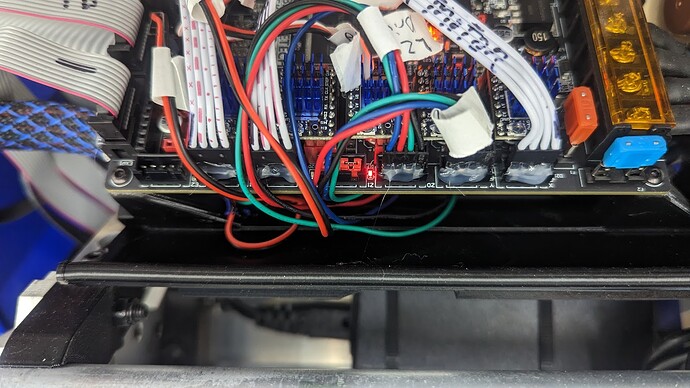

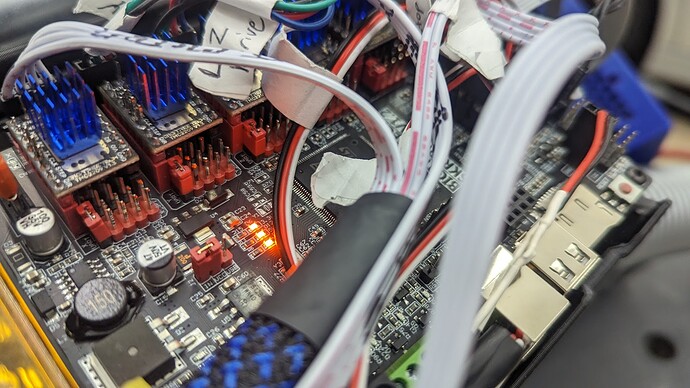

The problem is related to a design issue with the SKR Pro. The microprocessor on the SKR Pro is reading the signal pin of the endstop to determine if it is HIGH or LOW. The LED uses the signal pin as power. This results in a lower HIGH voltage. With an out-of-spec resistor or LED, the voltage never gets to the point where the microprocessor sees the pin as HIGH. Adding a resistor or disabling the LED results in a higher HIGH voltage, solving the problem.

It is highly likely that, if you return your board for a refund and purchased a board from another place, you would not have the issue. If my theory of a bad batch is correct, getting a replacement board from the same supplier might result in just getting another board from the bad batch.

when you say “disconnect the LED” can you please tell me how.

Anything that disconnects the LED will work. Taking a sharp knife and cutting the traces to the LED will work. Unsoldering the LED will work. From personal experience, I would advise against trying to pull the LED off the board. For me (not on a SKR Pro), this resulted in pulling the traces off the board. Note that while the suggestion of disconnecting the LED has been made on the forum a number of times, I don’t remember anyone posting back that this is how they solved their problem. Everyone seems to use the resistor solution.

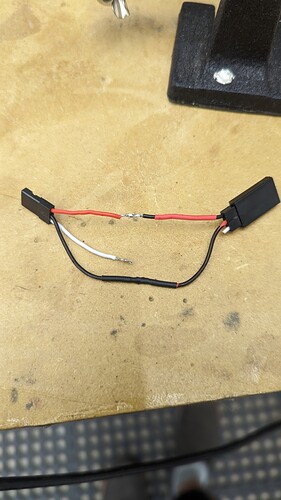

For the resistor, a value of 1.5K has been suggested, and resistors of values around 1.5K have solved the problem. It needs to go from the signal pin of the endstop plug to the VCC pin. In your picture, you have SGX listed. The ‘X’ pin is VCC…3.3V. Since you already have a third plug, it is just a matter of splicing into the signal wire to span the two. Personally, I’d carefully peel back a bit of the insulation on the signal pin (without cutting the conductor), wrapping the resistor lead around the conductor, and soldering it (probably optional). In this wiring, you do want to be careful not to short the VCC pin to the G pin.