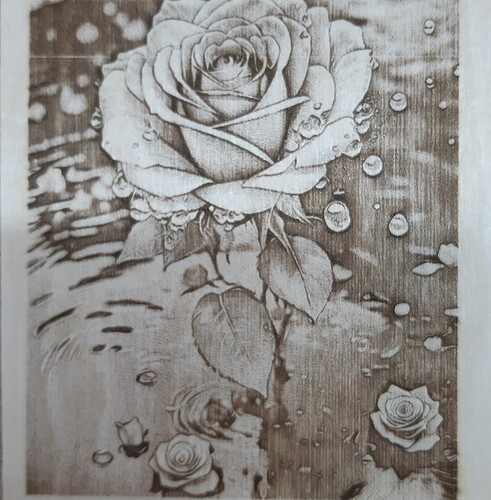

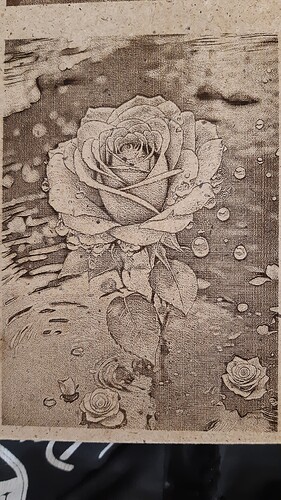

I use RAMPS 1.4 and MEGA 2560, latest firmware marlin 515. So, with normal cutting or burning with constant power, everything goes well. But when I start engraving a photo, vertical stripes appear. Moreover, they are the same on both light and dark backgrounds. What could it be? Gravity scale speed 700mm\min

There are stripes everywhere. Doesn’t depend on the material. At lower speeds, the frequency of the bands increases. At higher speeds, the stripes are less frequent but wider.

Try to decrease the line spacing for the laser. If you’re using lightburn you need to do it in the cut settings.

I have dpi 318 - 0.08mm

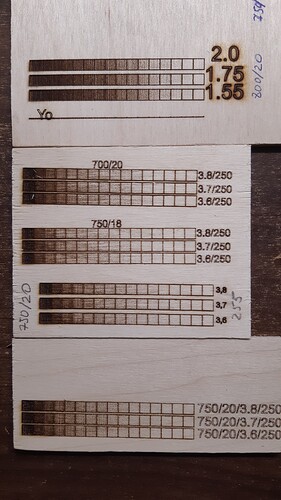

When I was doing laser engraved tiles, I saw similar banding, and was puzzled by it. My solution was to play with a variety of feedrates until I found settings that largely eliminated the problem. If I was going to try and solve this problem today, I’d start by decreasing the acceleration to see what difference that made. The acceleration can be set by g-code.

Also as to why the banding does not occur at full power, my theory is that, at full power, your burn lines are thicker, which hides the issue.

Thank you, I understand you. You correctly noted that the bands are constantly present no matter what power. what I noticed from the speed change. The higher the speed, the wider the stripes. at a speed of 600 mm/min they are smaller. I can reduce it to 500 but then engraving will take a very long time. Other guys are doing great at 700 speed. There may be a problem with the marlin firmware. maybe it’s worth switching to grbl?

It is possible the issue is Marlin, but I’d look to a physical cause first. I was thinking the issue was some sort of vibration in the movement of the machine. That is why I suggested you decrease the acceleration.

If you happen to have a Rambo board, it is easy to swap to GRBL to test your theory.

I’ll try at lower speeds. and in different places of the working field. Let’s see what happens. If the defect remains, you will have to switch to Grbl.

although I have a spare SKR board from a 3D printer

What I’m suggesting is changing the acceleration. M201 can set the max acceleration, and M204 will set the starting acceleration. Alternately you may be able to set them from the display. If a far slower acceleration (start or max) solved the problem, I’d gradually increase it until the problem reoccurs. Note this is only a guess, and changing the acceleration may not make any difference.

Just to be clear, acceleration and federate are different things. Reducing the acceleration may allow a higher federate.

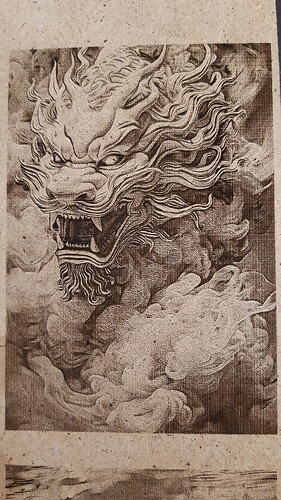

What I’m thinking is that the jerk when the laser changes direction is introducing a vibration, and the banding is a result of the vibration of the machine. Reducing the acceleration (starting and/or max) will soften the force when the laser reverses direction.

Edit: I just noticed there is a video associated with the M204 link about ringing in 3D prints. I’m thinking the banding in the laser has a similar root cause. The video suggests junction deviation as another setting related to ringing. Junction deviation can be set with an M205.

Edit2: M503 will tell you what your current settings are.

thank you I will try