So I thought I was in the homestretch of my LR3 build, but am having trouble on what I thought would be an easy part. I’m trying to run the X Belt and I can fit it through the slot but for the life of me there is no way I can fold it and fit it back into the slot. The slot in the printed part doesn’t look like there’s any way the belt would fit doubled up, and the working area is constricted making it harder. I feel like I must be doing something wrong or missing something. Any help would be appreciated

It’s enough to get a few mm in, the slot becomes tighter again so the belt does not slip out. I used a small screwdriver to stick it in tightly.

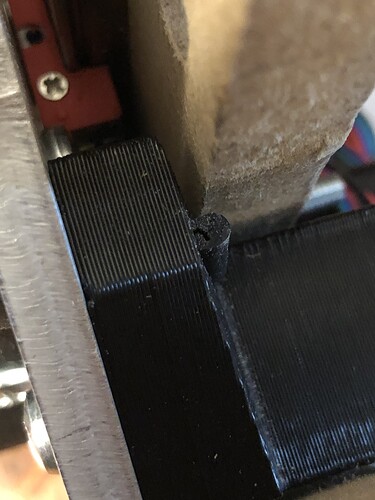

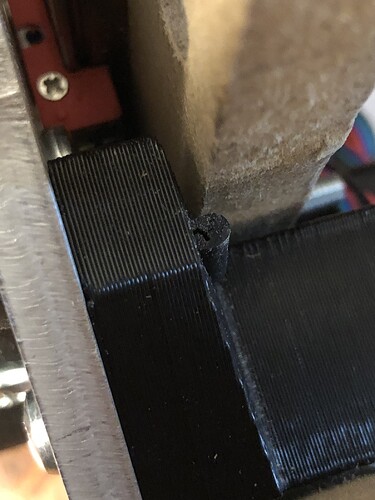

So I got it (sort of). I ended up unscrewing the stub and running the belt thru, and with it free in my hand, was able to loop the belt back thru. Then I fed the belt thru the metal plate and then screwed the stub back in. I guess my only issues are now - 1) the loop I left poking out of the stub is tiny - I don’t know how I’ll be able to pull it out if/when I need to. 2) even with how tiny the loop is, it still makes contact at the top of Z motion with the MDF piece. I can force it all the way up and then push it back down, but it won’t pass freely. When I push it, the belt leaves a black mark.

I’m about to just use the dremel and sand a groove into the mdf to allow for clear passage. Any reason that’s a bad idea?

Yeah I had major issues with sloting the belts too I think my 3d printer is to blame but I used some zip ties to hold everything in place.

I’m having the same issue as you had. How did you use zip ties? Do you have a pic of what you did?

I’ll take a look. Thank you!

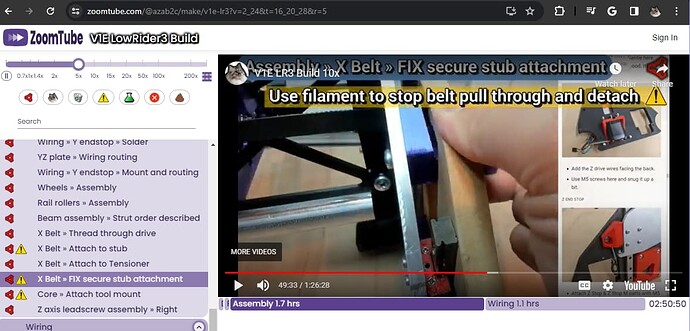

I had no idea that such a video existed! The problem I’m having is when I tighten up the x belt, it pulls out of the slot. I do have it folded over and partially pulled through but my 3d printer have left a slightly larger gap. In the video it says to use filament. Not sure what that means.

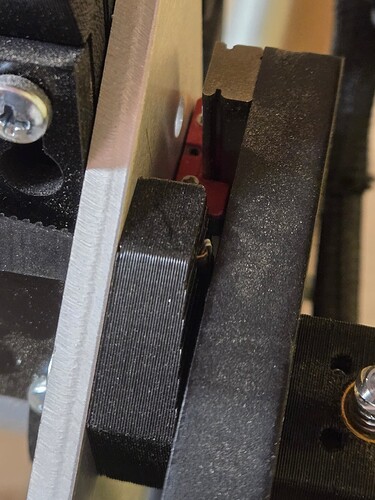

Here’s my setup, with hacky PETG filament (less brittle than PLA) to help stop the belt pulling through the stub.

Personally ran into problem with belt pulling through during assembly as well. I used 0.6mm nozzle and may not have oriented correctly when printing which may have contributed to the belt pulling through.

Someone on the forum suggested I try this, some people used zip ties instead. Hope that helps. Cheers!

That’s genius! Thank you again!!

I used a small ziptie (actually just a small part of it inside the ‘loop’ so it got stuck.

On my Y belt I couldn’t get the belt back in side the blocks so I made a loop outside the blocks by zip tying it into a loop.

Thank you for the response and picture! That definately helps!

Thanks again Aza ![]()

My X belt just came loose mid-job (luckily no damage done).

I cut a piece of a nail to put between the doubled belt, and filed a bit of the YZ plate away like you show here to make room for it.

Which reminds me to make a local copy of the build instructions, if the site were ever to go away I would have a hell of a time keeping the machine running without them…

I ran into this problem with my X belt coming loose. This has happened a couple times now. I was able to pull the doubled belt through the slot. I ended up bending a couple staples around the belt. It was low profile enough that I didnt need to notch the YZ plate.

Ryan explicitly says that you can just add a bit of filament into the fold. I added a small nail. The LR4 uses M3 screws in the current version, works like a charm.