Hi,

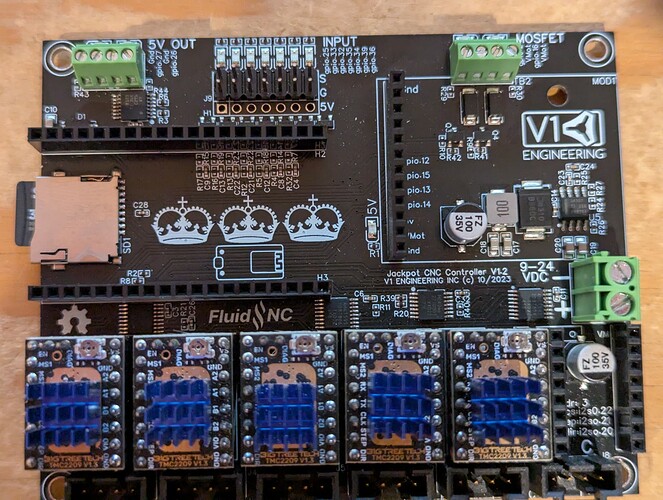

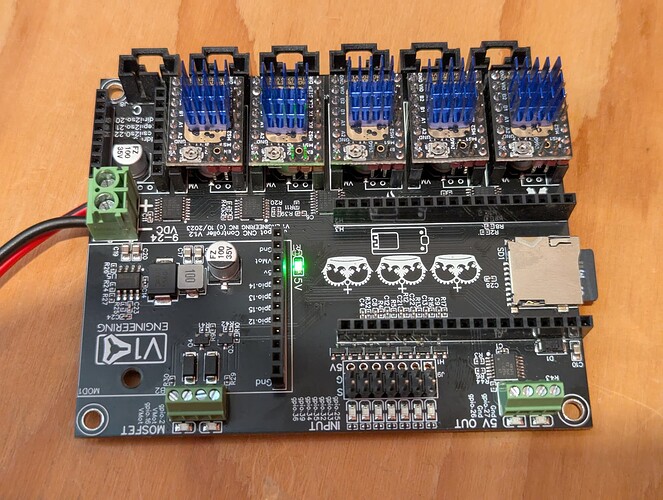

Since this morning, I’ve been having trouble with my LR4/Jackpot.

When I freshly boot my CNC, I can home all axes without any issues, but I’m unable to probe the Z-axis. I keep getting the following alarm:

<Idle|MPos:23.000,23.000,-17.000|FS:0,0|Pn:P>

G91

G38.2 Z-107 F200

ok

G90

[MSG:INFO: ALARM: Probe Fail Initial]

ALARM:4

G10 L20 P0 Z0.5

G0 Z25

<Idle|MPos:23.000,23.000,-17.000|FS:0,0|Pn:P>

ok

error:9

[MSG:ERR: GCode cannot be executed in lock or alarm state]

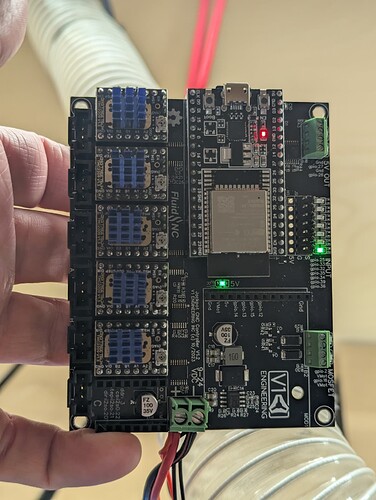

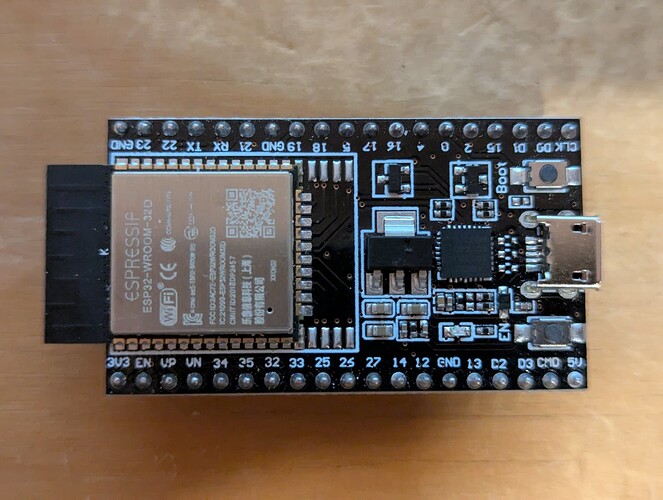

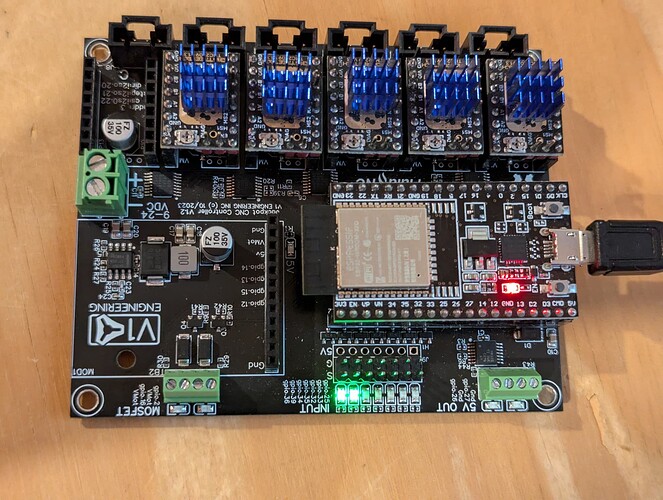

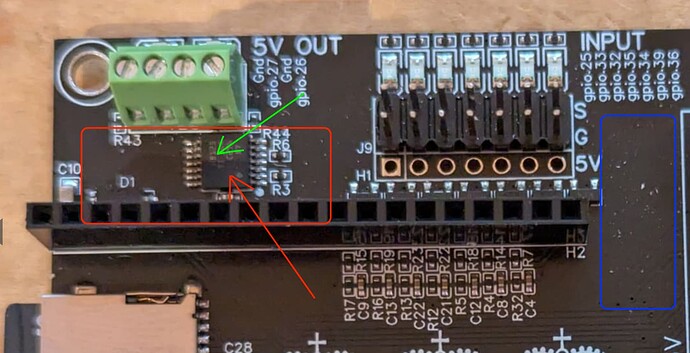

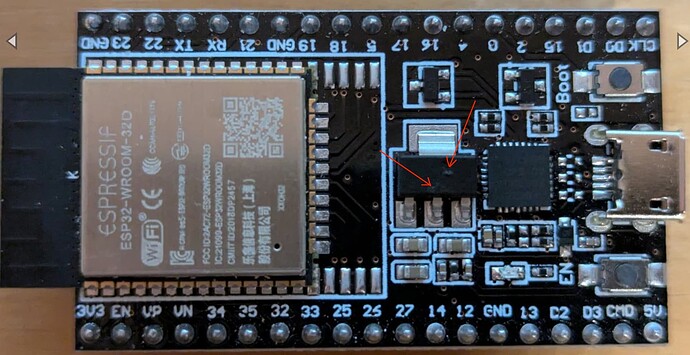

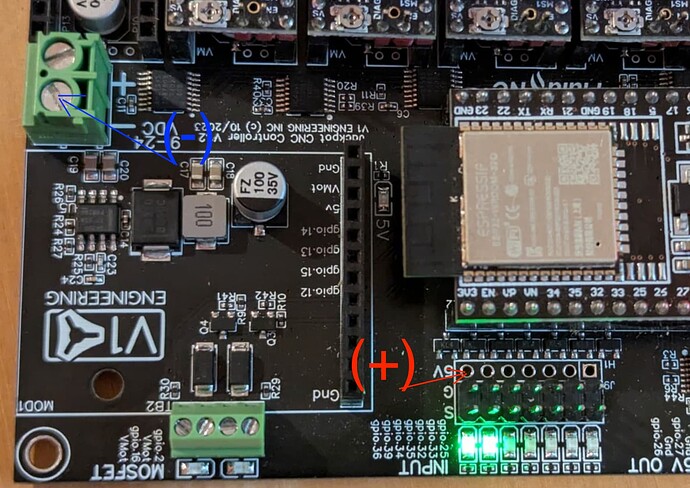

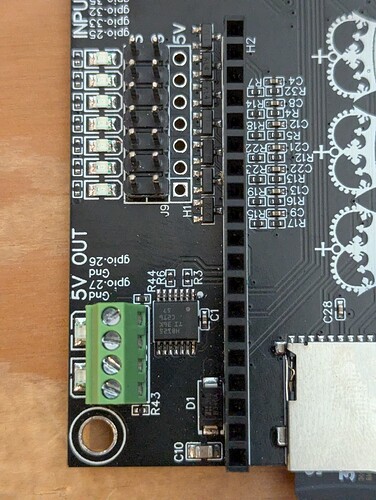

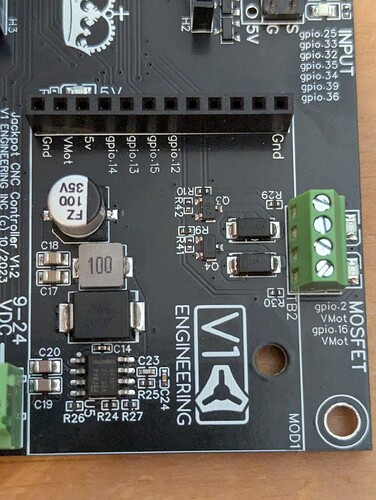

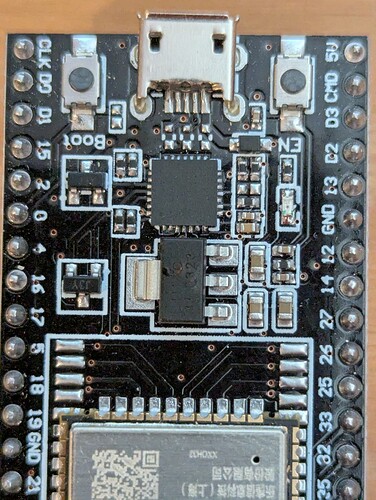

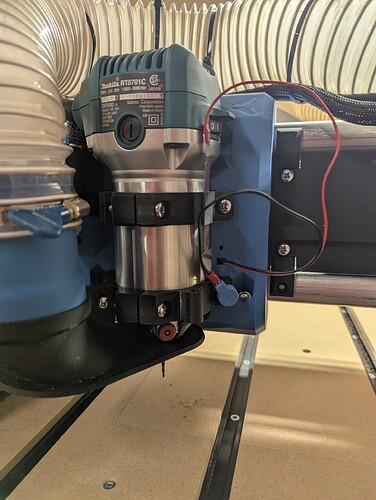

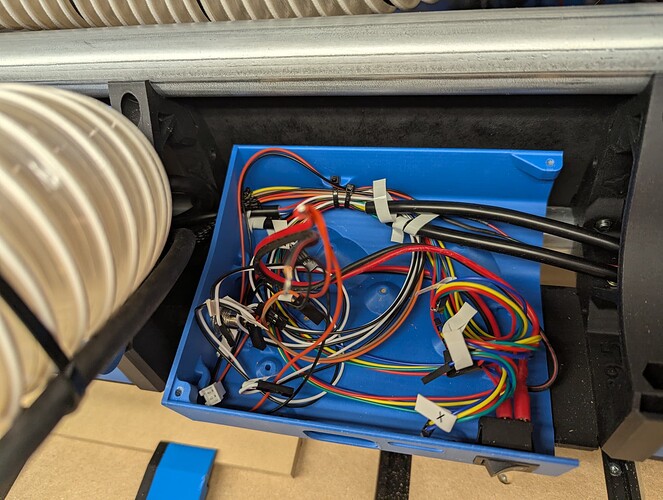

After some research and troubleshooting, I realized that the probe LED on my Jackpot is always on. Even after unplugging all the wires, the LED remains lit! The only way to turn it off is to remove the ESP32 completely—otherwise, it stays on, like this:

I tried installing the latest firmware as a fresh install, but it didn’t change anything.

Of course, all these wire manipulations were done with the controller powered off.

Do you have any other ideas I could try to fix this?

Thanks!