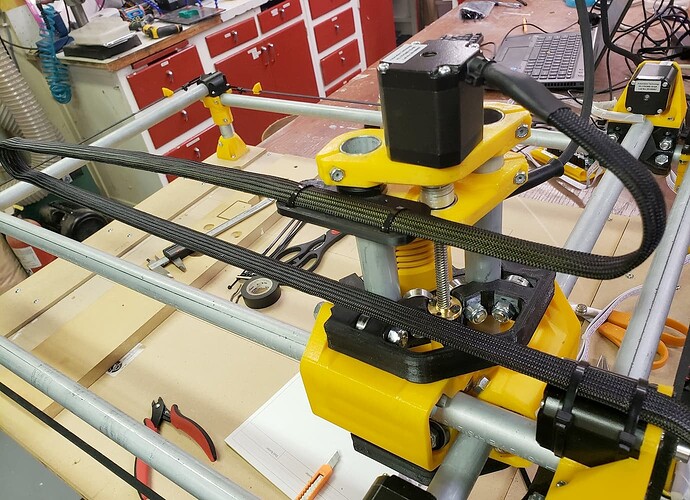

You can 3d print usable cable chain.

Some of our members also use tape measures as budget cable managers.

Below is a picture (this shows an MPCNC not a LowRider, but you can see how an ordinary tape measure can be turned into cable management.)

I printed my drag chain. Works well.

Wish I was back in Japan about now, just as the Sakura is at its best.

Wish I was back in Japan about now, just as the Sakura is at its best.

I think last week was probably the peak bloom in my area.

Just to confirm.

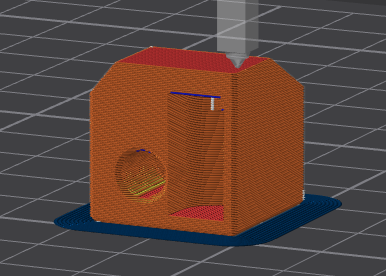

Is it okay to print all the print directions in the default state when downloaded?

I did a test print of the y_belt_min, Max_tension parts.

Yes. Ryan takes care to orient them in the correct, ready-to-print way as shared.

One thing to watch out for, some slicers have a “feature” to automatically flip them. I don’t know about your slicer, but i’ve seen this problem for example in FlashForge’s FlashPrint software.

Printed drag chain (it was a print in place one I found on Thingiverse), commercially purchased drag chain and the tape measure trick. I used all three and can say neither one of them was better or worse than the other.

Well that’s a lie - the tape measure thing is sheer brilliance and I had a kinked, not retracting tape measure at the time so didn’t feel any pain cutting it into pieces. It works great and is “basically free”.

Welcome to the family! I hope to get to Japan one day soon to compete in the ice carving competition in Matsumoto. I find myself incredibly fascinated by “Japanese ways of living” (according to YouTube anyway). AND I’ve literally just weeks ago discovered the concept of ikigai! It’s almost as though you coming here at this time was destined. Hahahaha!

Tanaka- how are your prints turning out? How are your preparations for a build going?

Sorry for the late update.

This is the current printing status.

Belt parts

z stops x 2

z stubs x 2

yz plates x 2

All except the yz plate were printed with a nozzle pitch of 0.16mm.

YZ plates are printed with a nozzle pitch of 0,2mm without any adventure.

Welcome to the family! I hope to get to Japan one day soon to compete in the ice carving competition in Matsumoto. I find myself incredibly fascinated by “Japanese ways of living” (according to YouTube anyway). AND I’ve literally just weeks ago discovered the concept of ikigai! It’s almost as though you coming here at this time was destined. Hahahaha!

Kelly, that’s great.

We hope you enjoy Japan and its culture.

I’ve been printing parts with my 3D printer since last week.

It will probably end on Friday.

Braces that have a large number of members and cover a large area take the most time.

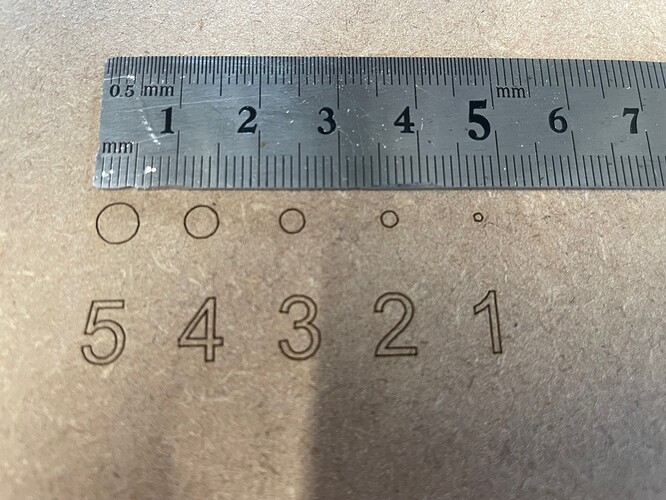

Hey you were asking about accuracy and since I did this test I thought you’d be interested in the results:

This is on a full sheet build LR4

So the motion system is accurate enough before taking into consideration lateral cutting forces, spindle runout, tool diameter etc.

Finally, printing of all the parts is finished.

I was putting the printed parts into the empty box for the 611 router, but it’s overflowing ![]()

That’s good.

It seems like you can get what you’re looking for if you assemble it properly and eliminate the shaking of the spindle.

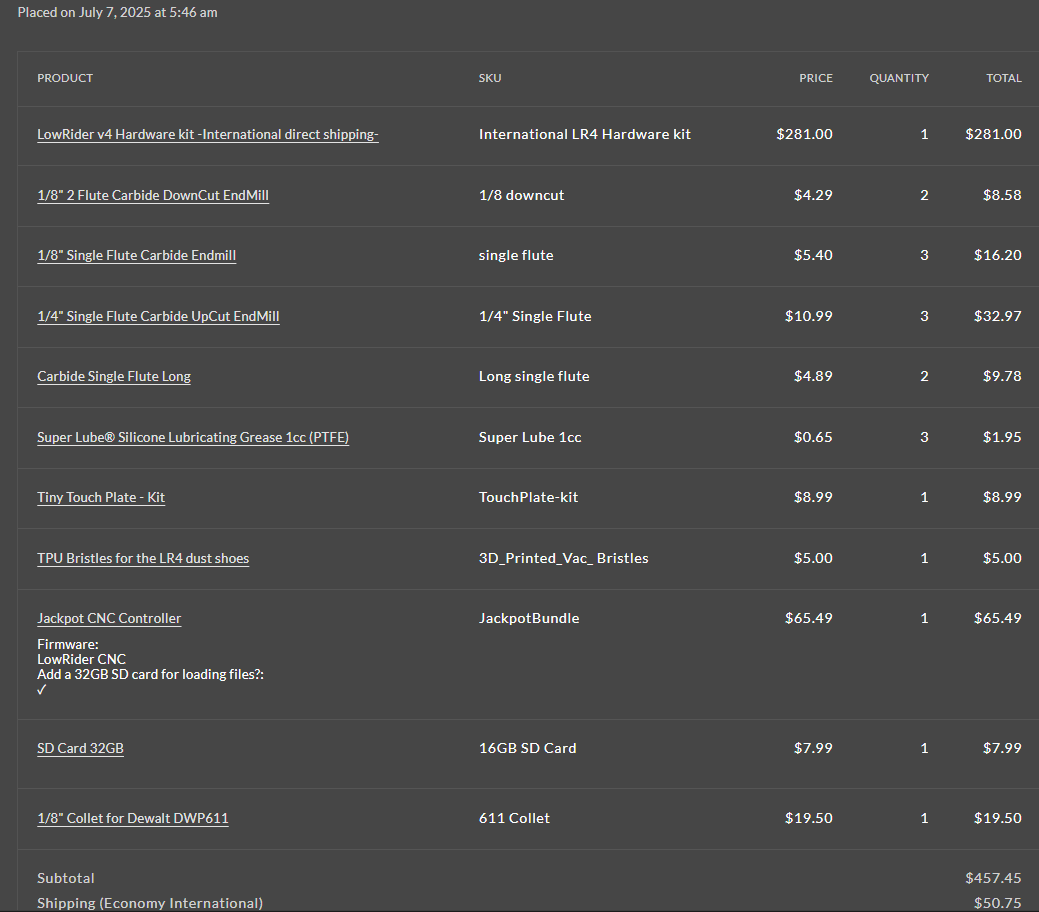

I finally ordered the parts I needed for my lowrider from the shop!

When I placed the order, I received an email saying that the payment was temporarily suspended due to suspicion of fraudulent use of my card, and when I called the card company just now, they said, “Security was activated, but there is no problem, and the payment was made normally after that, so there is no problem.”

If I wanted to order again, I would have to put everything back into the cart, and I thought it would be a disaster since I wouldn’t be able to buy the end mills that were out of stock, but I’m glad I was able to buy them in the end.

It such a bummer when card companies payments glitch like that.

I’m looking forward to seeing your machine come together.