I haven’t finished my repeat, nor do I currently have the Biqu extruder running in any of my printers.

I don’t print a lot of flexible / soft filaments- but, I do have a little experience that might be helpful.

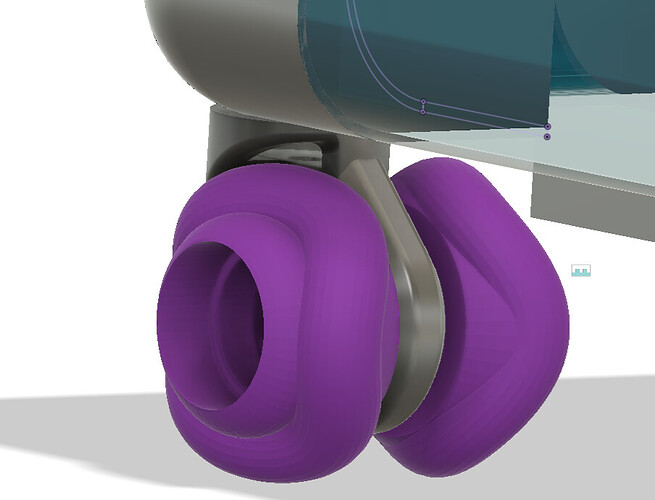

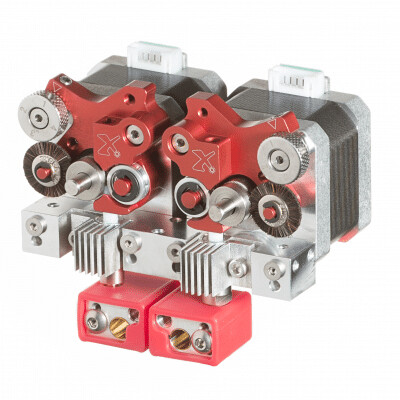

I have a pair of Flashforge Creator Pro printers, on which I replaced the stock extruder with a Diabase Flexion extruder pair. (One regular Flexion, one Flexion HT [High Temp] - but that’s a different story.)

Diabase, sadly, has folded and isn’t operating any more.

The Flexion extruder modified the filament path, had a cam and a set screw to set the clamping distance for the filament drive gear, and used a clever wiping wheel that cleaned the drive teeth as the extruder operates.

It had a bunch of other modifications.

I think the old shop page is still online at the link below, if you want a peek at what that extruder looked like.

[Side rant- Diabase also made a really awesome tool changer additive/subtractive multi-axis machine called the H3, which was impressive.]

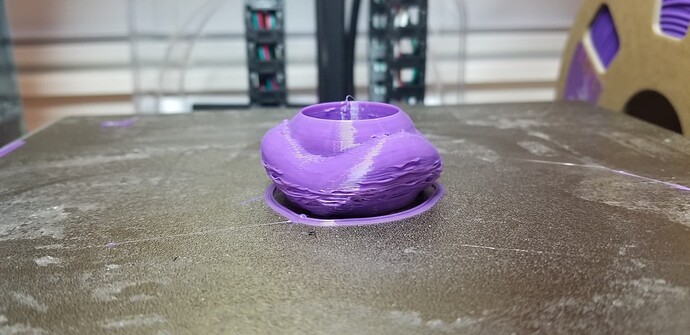

When I was printing flexible materials, I printed those on Kapton tape atop the metal build plate on the FFCP printers (I removed the factory applied print surface and put the Kapton over the metal.)

As others have noted, no retraction and moving slowly worked for me.

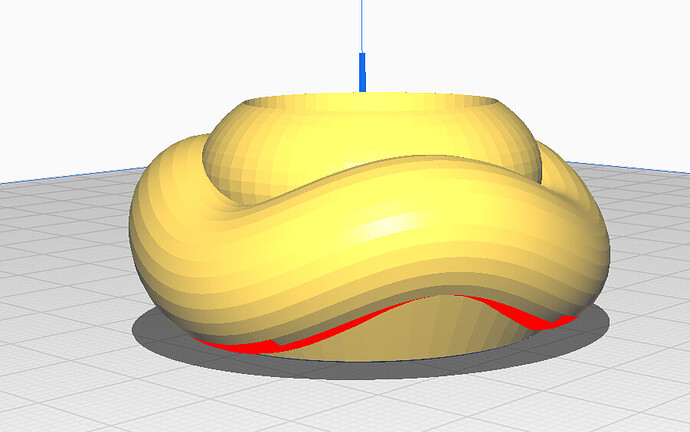

I also remember it being really, really sensitive to getting a good first layer. I aborted a lot of prints to fiddle and adjust every time I wanted to print with a flexible material. Here I seemed to have success with a bit more heat, slow, and a relatively thick first layer.

I remember that I turned off the cooling fan with flexibles, except on very thin layers, bridges, or overhangs because the flexible materials seem to like more layer bonding time. Any kind of overhang, though, are REALLY hard to print without cooling and the right speed.

It’s really important to fully constrain the filament path through the extruder. Flexible materials will find any chance to kink and go somewhere you don’t want. That usually ends up in a clog or bound up extruder. Direct drive is the way to go.

I also recall the flexible materials didn’t like really high acceleration and jerkiness in motion. Smooth and steady worked better.

I’ll look around to see if I have a profile for it- to start from.

What I remember was that if you have a metalic filament path through the hotend, the path needed to be well polished during manufacturing and if not it liked to jam.

I also remember the settings that worked for me on my FFCP didn’t work on others’ machines.

One community member at the local makerspace needed retraction and a lot more heat, and didn’t slow down. E.g. completely opposite all the advice and guidance that you find when searching.

It’s a reminder that when the base material changes, you may need to re-run a bunch of the calibration tests because your machine may surprise you with what settings it wants to be happy with that material.