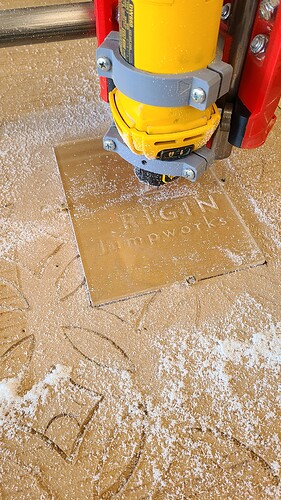

In progress. The one above took about an hour. This one says about 37 minutes.

The logo goes almost edge-to-edge. I just hope it wont hit my hold-down screws!

Edit: Whew!

Well, I think I have a favorite!

These “filled” logos were done with a .5mm ball end, .25mm DOC, 1000mm/min XY feed, 20% stepover, 150mm/min Z, 30° plunge lead in.