Hello! another linked to my long and slim plasma build so i thought i would say

The MPCNC design is made to apply a good amount of force… two motors per axis, both axis, and the relatively heavy core is strong to resist deflection when milling, ect.

In my opinion this makes it a tad slow. the thinner you go on metal the faster you can be cutting. for the primo i have it seems like the design is really thought out for general purpose CNC.

the core, and the extra tubing for the PRIMO two gantry setup, as well as the riding motors, all are unnecessary for plasma. in my opinion that weight flying around really cuts down on accuracy as you attempt to go fast. a plasma setup with a single gantry for the long axis and a riding shorter axis, as well as a tiny minimalist z axis would enable faster precision.

here is a really ideal machine IMO from ACCTEK.

the second axis rides on the first, with the Z being small and fast as well.

anyway I made my PRIMO with the thought of future milling or 3d printing, plotter, ect, so it is ok for me to go slow. maybe i will cut out dedicated plasma machine pieces soon.

the lowrider i cant speak about from experience but it seems like it could perhaps go faster due to less weight.

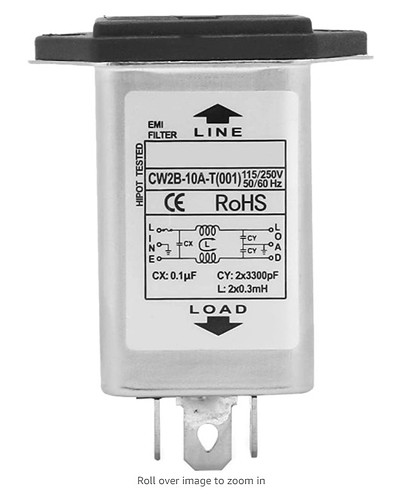

as far as electronic interference goes, it really is another whole dimension to this project. Not sure if you need to shield anything since your hypertherm will perhaps not have HF start?? if the enclosure can leak water it can leak EMI. im using a similar EMI prefilter before my power supply. stupidly i spliced a secondary power block in before the filter, it is causing my arduino to stop due to error. wrap all connecting cords in ferrite toroids, any usb cable too, and have a good distance physically from the torch head if interference is an issue. wrapping the stepper wires in copper mesh and ground the stepper bodies, using two layer stacked minimum optoisolator relay for plasma trigger (i trigger an arduino NANO with my RAMPS, which triggers the relays in turn) , these are all things that if done well, have worked for others and ive implemented them all with moderate success,

there is always time and room for improvement, as you know.