I have the cut60, listed at the top of this thread, I have not ran it under full CNC control yet. So I can not vouch for how clean or noisy it might be, but it does have the CNC port so wiring is easy and no hacking.

nothing good is going to come from me continuing down this rabbit hole… I already have too many projects going on

but here I am… diving in anyways. I’ve been collecting parts to build a new controller for the platformCNC sitting on my bench, but there’s nothing saying I can’t use it for something like this instead.

I would need to buy some stainless steel. I’m thinking I’d want to build a 2’x4’ one. I’m not sure what projects I’d have in the near future that would need a larger cut size. I do have the stainless steel I ordered for re-doing the Primo, but the largest ones are only 36".

dang. just realized I’d have to build a new welding cart to hold the additional tool.

That is a huge bummer. If you had a plasma CNC you could cut your own parts to weld up a custom cart…

This forum is full of enablers.

nooooo…

Heh, a couple of the guys on my 3d printer’s discord have upgraded to clearpath servos. I added up the cost and it would be almost as much as I’ve spent in total for my printer, including the upgrades. They’re like doooeeet!

Ok. I think I did enough research last night to go brain dead. The plasma cutter you picked up looks to work really well both as a stand alone and CNC… it’s officially jumped in front of the lathe for my next machine purchase.

I’m re-building a trailer we use to carry all of our camping gear and am planning on skinning it in sheet metal. This will come in handy for cutting the parts instead of using a cutoff wheel.

If the plasma table will already have wheels, maybe all you need is another shelf. Check out Spot Welder FTW! | Fabricating a Steel Shelf for the CNC Plasma Table - YouTube - he’s using his plasma table (and some other fun toys) to trick out his plasma table.

That’s a possibility.

I envision having a separate gun permanently mounted to the CNC, and then moving the plasma to the CNC when I need to cut something. This would leave the plasma on the same cart as the welder for when I’m manually cutting down sheet material.

I’m also trying to figure out how to get both the CNC router and CNC plasma built onto the same cart to free up floor space. In a situation like that, I wouldn’t want to move the entire cart in order to use the plasma manually.

I’m finding that a 3’x4’ cut size meets 95% of my needs for CNC router size. I’m hoping the plasma would be the same.

This is all in theory so far.

There are CNC torches that are straight rather than 90* - I’d expect they’d be easier to mount and manage on the gantry.

Exactly

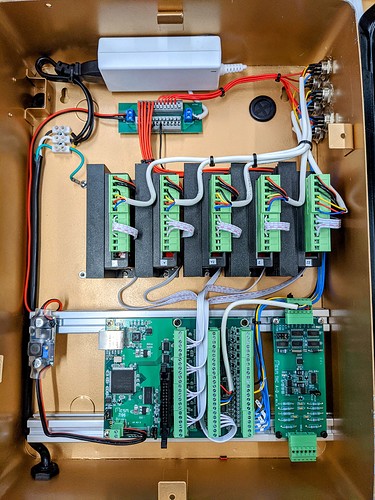

Nice control box.

I’ve been slowly gathering parts for a new box too. I’m going with all din rail mounted parts. I still need to design rail mounts for the stepper drivers.

It has been really frustrating for me, I feel like I am going into this very blind…even though I am following Kyle’s guide. I have not seen very many fully populated control boxes, so I was not really sure what to expect. Turns out there is a lot of din rail stuff available, and it is pretty inexpensive.

The plasma stuff is nothing like how we have it here. Lots of new information, lots of Jargon, lot’s of assumptions of knowledge and very few pictures.’

The only thing I have left is float switch, ohmic sensing, or both. ( really just want ohmic and a breakaway mount. I can not believe there are not a ton of ohmic sensing options that are just plug and play. If I make one I will surely make a board and parts list. Most of the plans are pretty vague. Heck I might just buy the one ebay option I saw.

I think part of the problem is everything changes depending on which plasma cutter you go with.

The one you have is CNC ready. One of the pins provides an output signal on the amount of power the plasma is using. Something I read said that you can use that knowledge to adjust the height. I’m not sure how. But I think that has to do with THC.

I also didn’t think your plasma had to be touched off. I thought the pilot arc or blow-back plasmas could be started as long as their within a certain distance of the work. I would think you could set 0,0,0 where you want it on the plate just barely touching the top of it and then have the gcode raise up just a touch to do the cutting.

This is all 100% theory for me. I have 0 hand on knowledge of anything I’m talking about here.

Yes, that is correct (from my limited experience), I have the thcad for that. I assumed that also meant it would drive until it hit a certain voltage for leveling…not how it works. No arc no initial voltage no initial height., that is a DUH moment for me.

Well, they can. From what I understand it can’t use that data to drive to the right height.

Major assumption here…I think the THC maintains the correct distance, not a set it and forget it type of thing??? So touch off, move to correct Z height (arc distance), fire the arc, give it a ~half second to stabilize then start monitoring the voltage of the arc and maintain that voltage using the Z. There are averages in their so things like crossing holes and other cuts don’t make it go nuts. So I think that means you can not fire a arc in random space and know which way to move to get the right voltage. Plus things like (plunges?) would get uglier than needed.

All of this is probably not really needed for thick metal, but sheet goods especially and thinner stuff moves a ton with heat.

Me too.

Now it gets real tricky is Ohmic doesn’t work on painted metal…so I plan on not using any or sanding it clean. That would be a bummer since I have already used my plasma to cut a hole in a hood, and had a second one lined up.

So a float switch would work, but where it is needed the most on thin material that can move inches when heated, well the float can deform it under its own weight and give a poor Z reading.

One guy on youtube setup a flood cooling system. His table empties into a bucket with a water pump on it. He said the flood cooling system helps keep the metal from warping while you cut. That might be easier than the ohmic setup.