It should be possible for a single pump/blower to retain suction with a few (or even several) missing cups as long as there is a narrow section for each suction cup or hole, so that if some vacuum leaks out it doesn’t drain too much. An air hockey table maintains pressure by having the holes very tiny.

That’s why I recommended to pick the cups from the bottom . The surface is close enough to flat and if you use the S3 cups I mentionned earlier they will conform easily to any kind of non flatness. They will work ok even with a small leak and they will only be affected if there is a big hole on the bottom of the cup (which is probably a non conformity in the first place so that’s a good thing).

Do not pick the cups from the top edge, that’s just asking for problems, the seal will be much harder to do and you’ll have a harder time later to push the cups against the other cups. I see no advantage of doing it this way aside from a marginal gain of speed on the vertical travels, which is a problem you can adress with other easy solutions like higher motor voltage.

Regarding the suction control, in my opinion you just need one vacuum pump (specific technology to be defined, could be a centrifugal fan, a compressed air to vacuum converter, a vacuum pump, I don’t know what is the standard in the industry but it’s probably easy to find out) and two solenoids. First one controls all the suction cups but one, second one controls the last suction cup which will be switched off half of the time when picking up shorter lines. I don’t see the interest of having dozens of ventury, it will be noisy as hell and if you lose vacuum on a cup it shouldn’t affect the other ones that much as long as your pump has a decent air flow. The cups you want to lift are very lightweight, it’s not like we are trying to lift hundreds of kilos.

An other solution that could perhaps work fine too would be to inflate a small balloon device inside each cup to pick them up. That would just use compressed air at relatively low pressure so that would be easier to make. There are lots of ways this could be built, but basically, the idea would be to make something similar to an air muscle, with a balloon and braided sleeves (maybe they are not even needed if the balloon is made of some tough enough material). The advantage would be that they would be easy to power (just compressed air through pressure reduction), but the inconvenience is that they would tend not to be straight when not inflated, so I’m not sure they would be easy to insert in the cups in a repeatable way.

I drew this up quick with my coffee this morning. Not to scale or complete with details. It’s just to explain the concept obviously. No vacuum required.

The blue parts are a soft foam. The rods are retracted into the plate to compress the foam and grasp the cup. The design could benefit by having a taper on the end of the foam to guide them into the cups among other things.

Hey guys, i’ve been in industrial automation and even working and designing big pick and place palletizers using ABB robotic arms. However for this purpose i think there is not much tech needed and the solution is getting tech driven. What i’d try to do here is let nature help a bit. The cops on the tray are naturally stacked (falling in the first possible space). I’d make an outfeed table that is slanted in a way that the cups arrange themselves, this seems highly possible with the required arrangement. No tech required there.

If the cups are not sliding very well you could just make the table vibrate, this would automatically also improve the arrangement.

Hi Bas,

the issue is that the cups have to fall into this very specific pattern. I tried if they by gravity fall into the same pattern on an ideal surface - they dont.

Also the paper inlay is creating a less than ideal surface. In conbination with the high height/width ratio of these cups there is just no way that they are going to align reliably.

This is actually very close to one of my initial conecepts. An Air-Muscle would solve many issues but they have a narrow range of diameters that you can pick up w/o overstretching the muscle. I am also wondering if they would show suficient longevity.

Bottom grip is actually the safest and they are ballow suction cups that could reliable mitigate any surface deformations.

However, this would require a filter station before this pick’n place action to make 99,9% sure that only open cups enter the pick up area.

This could be done as easily as with a PicoBoo One (if you know any alternatives please let me know) or with a very simply arduinio setup. (Distance measuring from the top; IF certain depth value is undercut -> THEN eject ELSE do nothing)

Have you tried vibrating the table? Normally empty spaces are filled naturally and the cups will fill the area in the most efficiënt way, i’ve seen it done with empty plastic bottles which although a bit heavier and sturdier would be a good benchmark. If not than you need to provide it with some guidance. But having a CNC palletize them… This is gonna be painfully slow. You’re talking about millions of cups, it’s gonna take ages (literally).

If it really does not work using gravity and vibration (or only vibration, since you can direct the cups with it as well) that i’d opt for a construction using a few push rods and a long enough outfeed line, or a container that is a perfect fit for the cups fitted sideways.

With pushrod construction i’m hinting at something like this: https://www.youtube.com/watch?v=bVHTubcphpE

Can you describe in more detail the defects that you are trying to reject? Are you saying the cups are sometimes squashed at the top? From an earlier post it sounded like perhaps they can have holes in the sides which is also a reason to reject?

I think that would be a good idea for heavier stuff with a lower center of gravity. Here the cups are very lightweight, tall and narrow, they have a really high chance of tipping off.

Yep.

I’m not sure what do you mean by that?

What would be a non opened cup and how would this happen?

I think they are saying that sometimes the lids stay attached, so if you had one cup with a lid, the cnc would just clobber them. So you would need to filter out the cups that still had lids first.

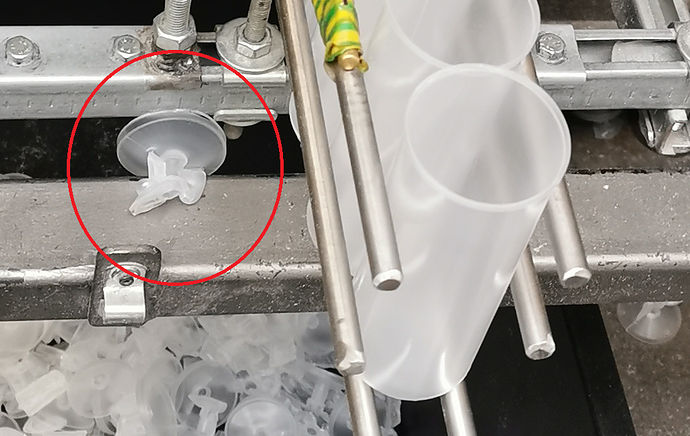

Ok, I guess it is that thing we can see on the picture here?

Well if that is the case I believe it is extremely easy to mechanically sort it out, that thing will be higher than the other cups so you just need some kind of thing that hits it and pushes the defective cup out of track. If the cups are ok they wont hit it and continue on their path, if they aren’t they’ll be removed. No need for any fancy stuff, a simple air cylinder or even some kind of triangle shaped thing can do that without any control circuitry. The metal guiding rods just need to be lowered at that point so that the defective cups fall over.

Tipping is very easy to prevent by applying a top layer, it should be high enough for the cups to easilly move freely underneath but lower than the diagonal length of each cup. This way they cannot flip.

That question can’t help but make me flash on Lucy & Ethel working in the candy factory. ![]()

From my cursory look over thing here are my thoughts. Some sort of fingers to close around the vessels will need space on each side to open and close. I know vacuums are used in PnP machines, but considering the depth the vacuum nozzle would have to enter the vessel I think you would be better off with a mechanical toolhead.

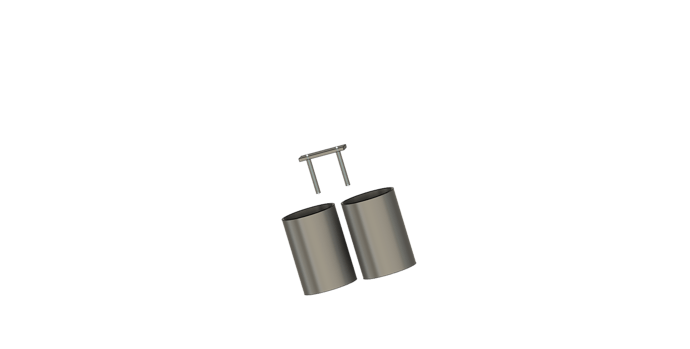

You could possibly use some sort of straight gripped fingers that close on the adjacent walls of two vessels. I’ve attached an example of the image I have. The fingers insert into two adjacent vessels, and one finger closes to bring the walls of the vessels touching. This would have the benefit of not deforming the sides with too much pressure, and the containers would be touching when released.

EDIT: You could also probably synchronize all the “moving” fingers with a single motor.

Make the track the cups are coming in on extendible, so it puts a full row of cups slightly above the cardboard. Use something to hold the row of cups in place and retract the six rods, letting the cups drop a small distance to the cardboard. Shift the box by one cup row then extend the new row over. No real need to pick up the cups, just to place them where they need to be, and where they need to be can be an object that you move. You could also do it with a flexible track that the cups move down on, move just the end of the arm and ‘poop’ each cup into the correct position.

Dear all,

it has been a while and boy has the world changed since FEB 2020. It seems we have avoided the zombie nuclear apocalypse by just a hair…

This project had been put on hold for obvious reasons in FEB/March but now I can able to continue along its path. Since then, I have done some research on the MPCNC and other aspects of this projects requirements.

In a hope to light the candle again on this project here is what I could bring together so far. (see next post)

.

Requirements before the MPCNC machine (not for the pnp-machine)

- cups need to be checked if open on the top

- cups need to be checked if bottom is deflanched

Requirements of MPCNC PnP.

- Control system needs to be able to handle conditional codes otherwise the "wait until row is complete wont work

- Control system needs to accept other sensor input to allow checks for tilted cups

- the longest axis is best served with a servomotor, the rest can be fairly standard steppers.

- We need X, Y, Z and gripper control so 3 main axis and 4th as actuator (can be binary valve-switch).

- a custom GUI or external controls would be really nice, but for now it’s not a must have.

- the gripper needs to be able to grip even or uneven amounts of cups (as there are rows of e.g. 16 and 17 cups)

Does anybody now which control software can handle such codes? As CNC machines are code-in part out controls, I’d need something more flexible. Like a whatchdog that listens for certain events to happen and then excecute a line or macro only.

Best

BW

You will probably need to roll your own custom program in for example Python, and use gcode over a serial communication to move the cnc axes.

I’ve done this for work, where we had our own sensor and needed to scan a target (to evaluate the sensor, not the target). A Python program moved the axes via gcode, and then communicated with the sensor (which was custom commands via TCP), and then communicated with a third system to download the data.

I think this would be good for your case too, where the robot axes are slave to a master program on a PC that integrates with a GUI, sensors, or even machine vision. Trying to force it into Marlin, or even Octoprint, is going to be an uphill battle. By writing your own top-level program you have unlimited flexibility, the downside being that you have to write code.