Hello everyone, I leave some photos of a spice rack made with the Lowrider 2 and 3D printing. A few days ago I placed a request with Ryan to upgrade my LR2 to LR3 or LR4 if anxiety doesn’t get the best of me. Greetings from Berisso, Argentina.

Looks great! ![]()

Those are nice spice racks.

I also like your work table. Have you posted pictures of you LR2 build and workshop?

Thanks!! My workbench also has some inserts made with my LR2. And it has many printed components too. I mainly use it as a bench router. I never posted photos of my Lowrider and my workshop. I’m going to do it.

Production is happening!!! I love it.

That’s a cool use of soda bottle preforms!

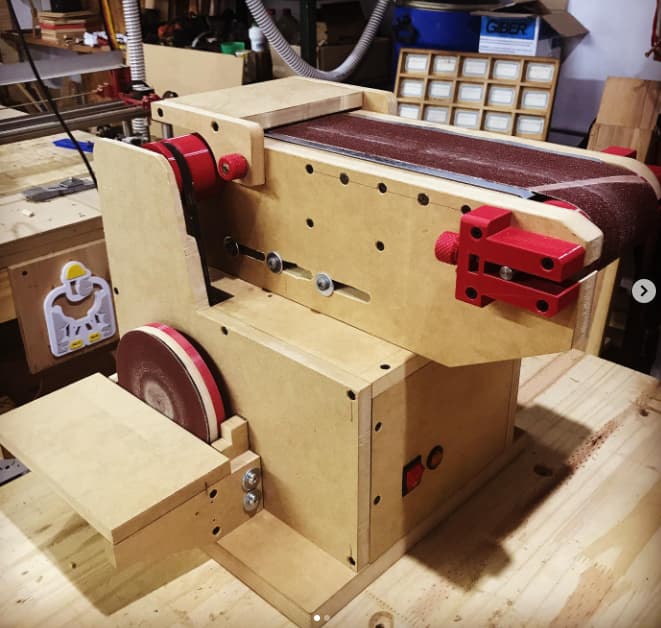

NICE RACKs (lol) sweet belt/disc sander too! your shop looks awesome, no small feat i’m sure. very impressive! i hope to build some tools like that sander myself soon. honestly this is why 3d printing and these CNCs are so cool… this is all about making something from nothing anywhere regardless of whats available.

how much would you say you are relying on 3d printing for your shop vs being able to purchase hardware? is it because of cost or availability or just the custom aspect?

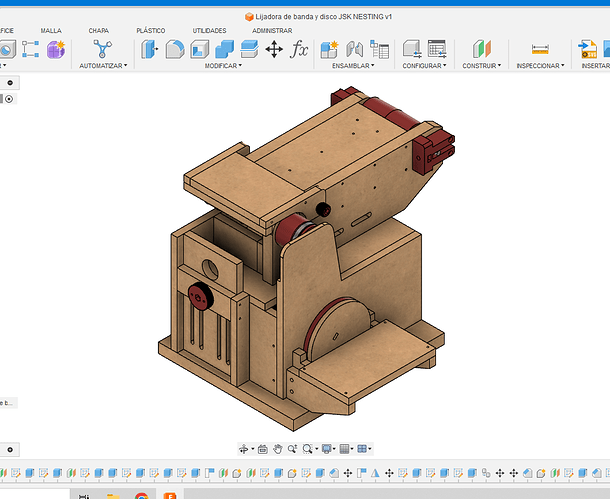

I take my workshop as a game for adults haha It is a place where I am not using my cell phone and social networks and that is already profit. The sander is an almost identical copy from a fantastic YouTube channel called JSK Projects. I reused my grandmother’s old washing machine motor. I used F360 for the design, the genius created by Ryan (LR2) to cut all the parts and 3D print in many parts in which the original has wood since the manufacturing seemed more practical to me (as long as the mechanical request of the parts he allows it). Regarding your question, I really like designing in F360 and 3D printing so if I can achieve something with the LR3 + 3D printing it is very rewarding. Thanks for the coment!!

This one needs its own topic with more pictures please. This is awesome. ![]()

It is a project that I really liked and that works so I promise to upload more photos, I can upload the F360 file in case it helps someone. On the JSK Projects channel you can see the complete manufacturing process. It’s very good, I’m going to try to paste the link to that video when I post.

Thank you!

Dude, that looks quite complicated and extremely well put together. I am jealous of you design skills. Well done!

Uh yeah!!! For sure!!! This is AWESOME!

Thank you so much! I really enjoy the design stage so I try to see if there is anything that won’t fit well in advance. That helps a lot. And it clearly took me a long time. Even so, I had to cut an important part twice. I had done the calculations for the perimeter of the sanding belt wrong. I will upload photos of the process shortly. Thanks again.

yeah, I could see me building this. i can get the sanding stuff from harbor freight, you ahve a large adjustment in there for different size belts.

VERY NICE!!

YES!!! EXACTLY! → “machines that make machines”, as it should be.

i am both in awe of the advance of tech in my 40 years on earth and at the same time disappointed that the only folks that seem to be using it the way (i feel) it ought to be used are regular people like us and open source developers etc

should we not all already have a machine in our homes to print the simple things we need vs shipping things across the world etc? i saw some post on reddit where the individually packaged pear slices were grown somewhere down by you in S. america, shipped to maybe malaysia or something for “canning” then back to usa for sale. not entirely relevant but i think you get my drift.

and as far as the workshop… yes i agree. worth it regardless to DIY. time spent in the shop > time spent driving to the store etc.

having things just the way you want them in the shop etc can be both an immense blessing and an OCD curse too. ![]()

as long as its learning and enjoyable i do it. the critical thinking/learning portion in addition to making it with your own hands has many proven benefits for the brain.

que crack!!!

I lived for 4 years in Argentina (capital federal). I miss it nearly every day. So nice to see your projects and your workshop. Please keep posting updates ![]()