I’ve been cutting some 3/4” laminated oak plywood from Lowe’s on my LR3. The first batch went well, but when I swapped in the next board and finished the probe I hooked the wire to a cable tie loop like I always do but somehow it snagged, bound up the X axis, and dragged the router in a diagonal over my board ruining the one remaining clean piece of wood I had left.

No problem, off to Lowe’s. Bought some more sheets, had them slice it in half lengthwise, got it home. Realized that for whatever reason this batch looked the same and calipered the same but was noticeably heavier.

First part went fine, then all of a sudden the sound of not moving. The X axis belt had come out. I’m probably doing something wrong there - when I do the fold and pinch on the right side (the fixed one) I had a problem where the belt was jutting out a bit and blocking the Z-axis rise, so I wound up cutting it flush and hoping friction would do the trick. Which has worked fine for six months now, but today I guess it got pulled a little too hard. Another cut shot.

Reattached the belt (fortunately I had some extra on the far end so I didn’t have to rethread it in place.). Had to cut off the bit that stuck out again.

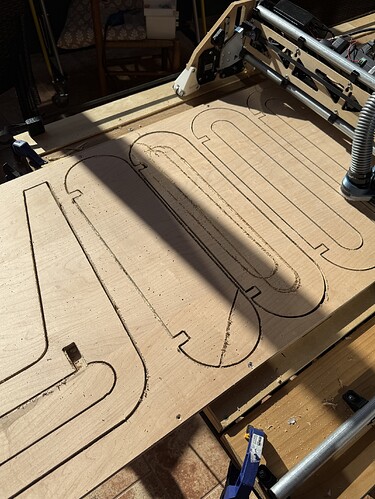

Reset again, going ok, and then the bit gets stuck (this wood is clearly harder than the last batch) and shifts the whole axis by a 1/4 inch, so now it’s cutting spirals instead of following its path.

Replaced the bit in case it was getting old, and switched from a single flute upcut to an unlabeled bit but I think it is an up and downcut bit in one. Also hopefully sharper. So far it’s cutting much cleaner.

If I ever get done it should be a side table (plans from Etsy but it’s otherwise working out ok).

Hoping to finish the remaining slats today and then it’s pretty much just laminating the exposed edges and hoping it’s stable.

Have fun!