I didn’t drill out the holes, no. Instead, I ran a bolt through and then kept turning it to strip the plastic threads. They’re still really tight - I basically can’t just push the bolt through the hole by hand. I also just finished replacing the 1 1/2 inch bolts with fully threaded ones.

If I had a choice I would not use fully threaded ones.

Someone mentioned that they had problems until they swapped out the “shanked” bolts. I agree that the unthreaded section would seem to provide a better connection with the bearings, but there is also a rounded shoulder between the threaded and unthreaded sections, and I thought that might be contributing to my wobbling problem. I’ve gotten it tightened up some, but I’m still worried that it might not be rigid enough once it’s all hooked up. We’ll find out in a day or so, when I’m ready to test it!

I bought an SKR Pro 1.2 and a set of 2209 drivers. I know I saw some directions somewhere about bending or cutting a pin on the 2209s, but I can’t find it now. Can someone point me to it (or did I imagine it)?

Perfect! Thanks, Ryan!

I like your knob, if you haven’t already done so I recommend putting Loctite on the Z motor screws.

My Primo just got put to work the last couple week and they kept rattling loose.

Good point about the loctite - I’ll do that! Glad you like the knob. I find it really helpful to be able to run the lead screw up and down when unpowered.

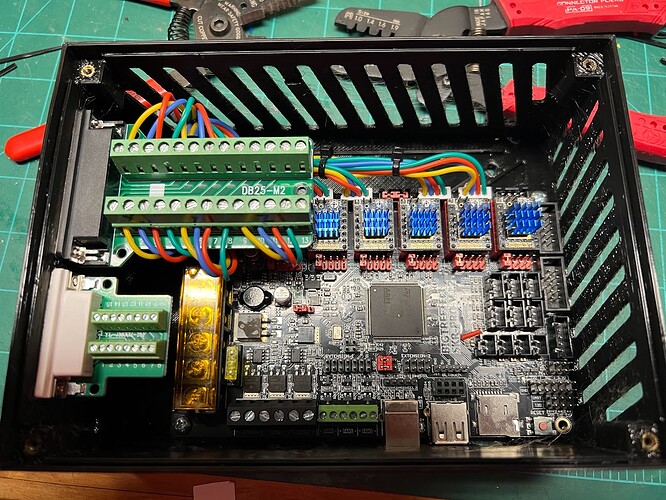

Progress report: just finished wiring the stepper drivers to my DB25 breakout board. Next will be the endstop connections to the DB15, wiring the cooling fans (for the control board), connecting the display, and wiring up power.

P.S. love my PA-09s for these JST-XH connectors!

Where do you connect the fans for the control box? I was thinking about using a 24v power supply - can I still use 12v fans if I do? Any thoughts on 24v vs 12v for the MPCNC?

Running a 24V fan on 12V is not efficient, but it works. Running 12V fan on 24V seems like it would kill it quickly.

Maybe I phrased the question wrong. The duet board on my D-bot has 12v outputs for fans, even with 24v input to the board. I was wondering if the SKR Pro v1.2 had something similar.

What are the pros and cons of 24v vs 12v? I would think 24v would run cooler. I can always get some 24v fans, or more likely, just throw a buck converter on there for the fans.

Hmm. Probably should look at the laser driver too to make sure it can handle 24v.

That’s a whole kettle of fish right there…

I have run 12V fans on 24V, with the controller set to a maximum of 50% PWM duty cycle. It works, the fans do seem to die a bit sooner, but cheap 12V fans never seem to last that long anyway. You can configure the duty cycle in Marlin. I usually switch to 24V fans as soon as they’re available when I do this. Since the 12V fans are cheap and plentiful to get and 24V ones are less convenient, I’ve done this for my 3D printers a number of times.

Ok, 24V power… tl;dr version is that it allows faster rapid movement, zero real benefit when the CNC is actually cutting anything, except maybe foam.

It does not. The drivers are constant current drivers, not constant voltage. They send the same current no matter what the input voltage is.

The one area that the 24V has an advantage is when the motors are moving very fast. When that happens, the 12V can be insufficient to reach the current you set it for, and the torque will drop. But that isn’t a problem for us, because the faster moves aren’t high load moves (we cut slow) and the limit for saturation is very high.

A 3D printer moving at 400mm/s can have a difference between 12 and 24V on it’s motors. But the best reason to use a 24V on a <100mm/s machine is heating the bed and extruder faster. Neither of which are on the MPCNC.

Okay, all good info! I have several 12v power supplies - I’ll use one of them and save the 24v for a 3DP build.

Thanks Jeff and @SupraGuy!

In the pre-configured firmware, is one of the fan outputs already set up for controlling a laser?

Or maybe I should ask, which one is set up to control a print cooling fan? I think that’s the one I used for laser control before.

BTW in answer to my question about 12v pins - there are some in the block of pins just above the reset button and UART pins. There’s 12v, 5v, and 3.3v available. Since they’re labeled, I’m guessing they output those voltages regardless of input voltage. I’ll use those pins to power my control box fans.

The SKR Pro docs that @vicious1 linked me say to disconnect the display when updating the main board. Then it says to put an SD card with the .bin file in the display’s SD card port and reset it to update. At this point, should the display be connected back up to main board? Can it be powered from USB, or does it require 12v?

Also, still need to know which fan output is for the cooling fan (laser).

Well, I think I figured it out. I was able to update the TFT by connecting all the plugs to the main board and connecting the main board to 12v. As far as the cooling fan question, I connected plugs Fan 0 and Fan 1 - pretty sure it’s one of them.

I saw a touch screen somewhere that had a dedicated laser menu - any idea where I might find that? Or is there somewhere I could learn how to make my own custom TFT menu? The one I just loaded is pretty much dedicated to 3D printing.

The current stable version yes…but since then it has been taken out of the nightlies because it has been totally revamped by Marlin, so I/we need to totally retest it all.

Yes

Make sure everything else works before you involve a laser.

Old and outdated. The TFT evolved quickly and outgrew those extensive edits. The edits just turned it on and off. You can still do that with the terminal or gcode. Best to stick with Marlin mode anyway.

Of course I will make sure everything else is working before involving the laser. But the fan connections are not easy to reach once the board and all the other wiring is installed in flyfisher’s case, so I was hoping to pre-connect the wires, which is what I ended up doing on fan0 and fan1.

Seems a shame to stick to marlin mode when I have this beautiful TFT screen here. But I’ll figure it out later. I can probably just hook up the pendant I built back in the day with Leo. It has dedicated buttons for laser at 10% (for focusing and aiming), as well as jogging and homing.

Progress report: control panel is all wired up and firmwares installed. On the CNC, all motors and endstops are wired and the cable management all done. Just need to terminate the wires to my db25 and db15 breakout connectors, and I’ll pretty much be ready to start testing motor directions and stuff. Need to design a housing for the breakout boards eventually.

Starting to look like a CNC again!

There is/was/might still be a random bug in the TFT. Marlin Mode is the most safe route for now. I am checking updates every few days. I have not seen the bug lately in my daily use but I am using the nightlies. If you are doing testing TFT mode is fine, just know if it randomly stops try again with Marlin Mode.

The other reason not to use TFT mode it is uses it’s own Gcodes and scripts to do things that are 100% not the same as Marlin mode. So if you want to use it, it is beyond our capabilities to fix bugs in that side at this time. It is above my current programming skills to make any changes…and they are not super receptive to them either.