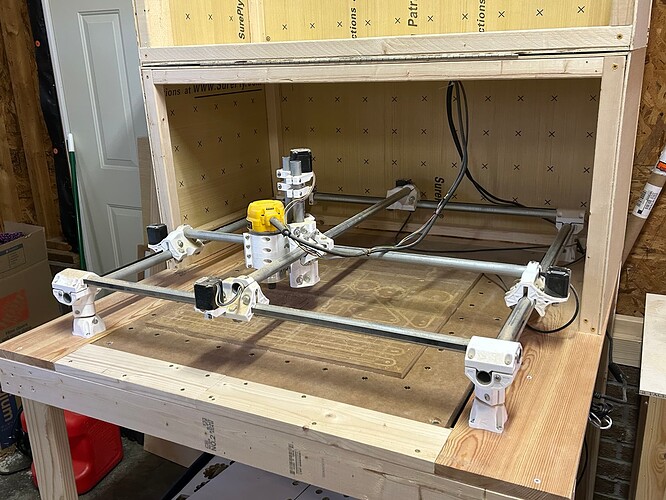

My MPCNC rebuild is up and running! This is a reincarnation of my Burly build that I originally built in 2018. After several rebuilds, teardowns, and schlepping parts through 4 moves and 3 states, I’ve got a working Primo.

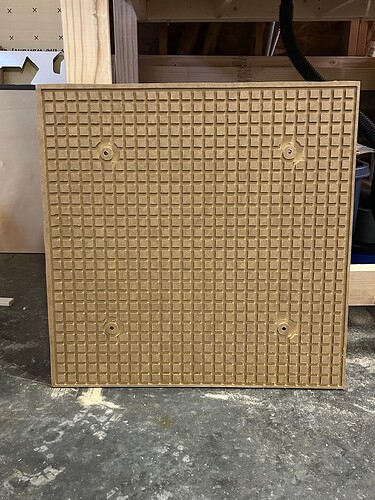

The working area is 2’x2’, and uses a swappable 3/4" MDF spoilboard I recessed about 10 mm into the table. There are also 1/4-20 threaded inserts surrounding the spoilboard for workholding.

The machine is driven by CNCjs on a RPi 3B+ connected to a miniRambo. The electronics area could be cleaned up and enclosed, but I was impatient and wanted to get cutting

There is also a vacuum port on the bottom, which can be used with another spoilboard I cut to be a “vacuum table.” It works pretty well with a downcut bit on EVA foam!

All of the work area is enclosed in a hinged lid made of 1/4" plywood and 2" furring strips. It is pretty lightweight and keeps the dust mostly contained.