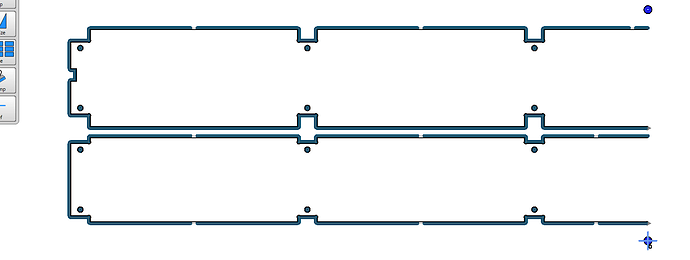

For a quick validation, here is half of the job, I am setting the origin to the center of one of the index pin holes. Am I still missing something?

Looks okay to me

Thanks for the help, the parts turned out first try.

A couple of blemishes due to warpy 5mm underlayment but they installed easily enough. The two sided cut was actually more straight forward than expected. I did end up using furniture makers dowel rather than the long turned dowel. The turned dowel is way too inconstant. I used 8mm peg and cut a 7.5mm hole which gave a tight fit which only took a couple of taps.

I use .25 index holes and then a pair of endmills to align.

The hole setting are easy enough for me to figure out. The cut lines since they’re open vectors to CarveCo, I assume cut setting are just along the vector and offset half diameter of endmill?

I just used engrave outside with manual toolpaths in Estlcam. Don’t know about CarveCo though, sorry.

In carveco you can select the two open vectors and select join with endpoint. Only problem with doing this is if there is a space between the two vectors it will move the endpoints together which would throw off your street line. In that case you would have to use connect with line.

Well, I just ordered the hardware kit with plates and board. I will do some trial on flipping too large a piece on my smaller cnc until I get my LR4 printed and built.

Haven’t ran the quick test on my Genmitsu 4040Pro yet, but I followed along with the video when setting up toolpaths and they all appear to be worked out just fine. I thought about using an old piece of 1/4" Luan and trying to do one strut plate on the 4040, but that would be 3 moves in total. Maybe I’ll get bored and try it.