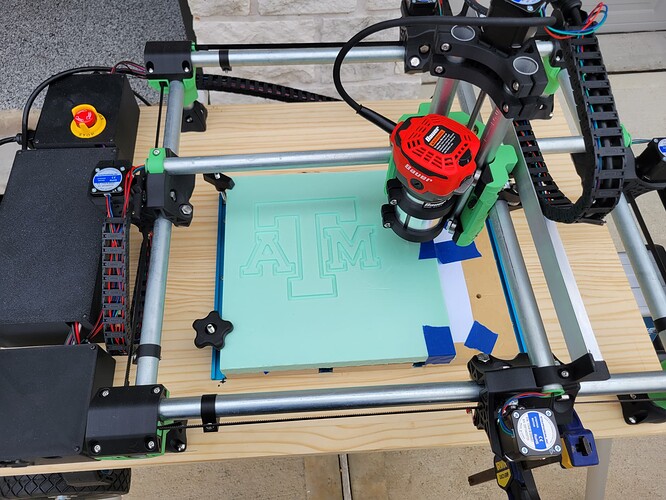

We have chips! Well foam chips anyway! I am going to callthe build “complete” though from having 3d printers there really is no such thing but it’s cutting and mechanicals seem sound!

I still need to check the squareness. surface the spoilboard and I can already tellI’m going to want a dust management. I already have a shop vac and am thinking I just find a mount and modify if needed to hook that up. I cut the foam outside so no big deal but it still gets everywhere!

I’m really liking fluidnc interface so far. takes a bunch of steps out to be able to just save the CNC file from ESTLCam and upload it over Wifi to the SD card then fire the job off all from one webpage wihtout needing a middle step (repitier host, etc)

I would like to tackle dual endstops eventually and auto square etc but baby steps! My next tasks is really reading/reasearching more about CNCing in general. I am a total newb so want to learn about feed rates, cut depths, what the different bits do best, etc etc etc.