Sorry, I didn’t see this, I still have a burly setup

I will check right now.

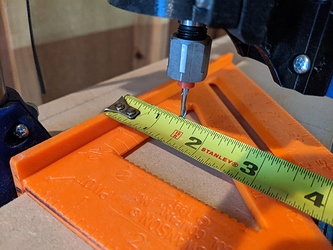

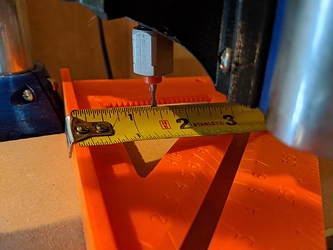

45 degree from feet. bit is align with the cut at the feet.

I can’t measure any other way cuz of cable chain and control box.

Dang that is a huge difference. 12mm 1/2"…not happy with that

Ready to print new parts.

[quote=“vicious1, post:685, topic:16891, full:true”]

Dang that is a huge difference. 12mm 1/2"…not happy with that

[/quote] And you don’t gain it back in the opposite direction?

If nothing else changed except for the DW660 sitting closer to the Z rails, then that would happen. So it’s not a bad thing unless the working space is smaller, right? Or am I missing something?

Can you expand on this please? Which area specifically did the all thread ruin the machine? I was thinking of using allthread for the Z axis m8x130mm bolt on my current Burly build.

Ryan/beta testers. What spindle option is the Primo being designed for as “stock”? I have a DW611 (DW26200k) that I will be using in mine and just wondering about mounting options.

For the Burly, the “standard” recommended version for the US is the DW660. The DW611 is much heavier. I don’t think this is changing for the Primo.

It has no but a 52mm and 55mm spindle mount are ready

The 1.4 pound difference is too much? Asking because I have not decided on a spindle yet

Generally speaking, the more weight you have on the end of the z-axis, the more inaccuracies you will get. This will have more of an impact the longer your z-axis is. Is a 1.4 lbs difference too much? I don’t know. Your use case, and your z-axis length definitely factor into this.

I read that as him having the allthread version. And he destroyed it. Not that allthread destroyed it.

But, we’ve had a lot of Z issues go away when we switched to the leadscrew. It is less friction, and the motor doesn’t have to move as fast. Is there a reason you are trying to use allthread?

Ah, makes sense. So if I’m hoping to get 24”x24” working area I should find the lightest spindle I can?

I am not an authority on this matter; but if you don’t have a specific reason for getting a 611, (its my opinion that) you shouldn’t. The 660 is smaller, lighter, cheaper, and has more than enough oomph for the MPCNC. I would only consider the 611 if you already have one and are looking to repurpose it.

I’m actually hoping to find a nice quiet spindle, routers are so loud

Once it starts cutting and with a vac, it’s kind of a wash either way.

As Barry mentioned… most of us have figured out at this point that the spindle is quiet compared to the sound of the material being cut. Doesn’t really matter which router you use.

My 1hp dust collector is fairly quiet, and piped from a corner. Mostly do v-carving as well