There are always sequels

Wow, you really do trust your printer. Why not throw a core in for good measure?

I thought I fixed the 23.4 in my other reply before posting but realized I didn’t and didn’t see an edit button. I understand the O/D vs I/D was just confirming my suspicions.

I did throw the number into google and it came up with multiple retailers with the same item.

As far as the 10’ sticks I plan to rough cut them in the parking lot same as I did with the pvc I bought (needed 6’ and 3’ so I cut it at 6.5’).

Okay if anyone has an order form last night or today I will work on them in the morning.

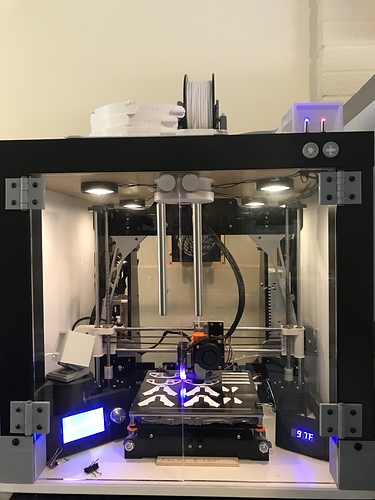

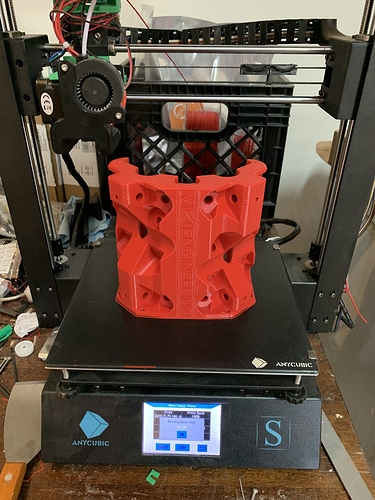

Washer backed up flooded the hallway, and into the shop. Had to rip out a bunch of the laminate and some cleanup. Came into the shop to get out some orders before I dealt with that mess and 5 orders in the label printer took a dump…so I am going to work on both of them and get the backup printer going. Have no fear, orders will go out ASAP. (one printer stopped working as well, jams in the middle of a print…I will rebuild it to a V2).

And as bad as it sounds I am in a pretty good mood.

Kickin names and taking ass

Kissing not taking  I may have been doing it all wrong

I may have been doing it all wrong

Just had to replace my kitchen island thanks to some leaking. Not good. Still waiting on state farm to cut a check…

So… I guess that’s what happened to my order. (#13290)

All good, it’s not like I’m pacing the floor and refreshing my order status page every 15 minutes.

For an order, is there a choice in the colour scheme?

I do have some questions about dimensions. Taking measurements off of .STL files isn’t one of my skills, and you know what they say about assuming things.

On the video demonstrating the endstops, they seem to be on the mounts on the bars, but I see no provisions on the stop blocks for them. I do see a couple of blind holes on the trucks though. Are these for the endstop mounting? What size/spacing are these holes? I have a pile of RepRap endstops with 19mm spaced mounting holes, but I also have a couple dozen microswitches which can also serve. Having the parts already is one reason why I’m opting to do the dual endstops. Since I’m waiting for stuff to ship, I figure that I can/should get whatever else I can prepared and ready.

Oye…not at the stage of putting it back together yet. looks worse than this morning.

Unfortunately, no

You did an echeck those take a while to clear.

No, kinda. I have some help and I believe he has a few in a different color scheme than me, for the 25.4 only. Maroon and grey instead?

I can check in the morning, but I think that is right, whatever the standard spacing is.

Ah, crap. That was supposed to be an instant payment, it’s been a while since I used PayPal, I guess I messed it up. Hopefully won’t take too long, the funds are already out of my bank account. Patience isn’t always my strong suit.

I’m not too invested in the colour scheme. I’d probably rather that it didn’t look like it was made by Hasbro, but other than that, “Whatever is ready to ship” when it’s time to ship will do just fine. Partly it’s a matter that I’d like to have matching filament on hand if I gorilla something and break it. I do work on my own car, lol. I also have an in-lb torque wrench, because I’ve stripped threads in aluminum castings, and never want to have to fix THAT again.

A couple of personal disasters reduced my budget, so I’m looking to save a bit of cash, which put the kaibosh on buying the Dewalt 660. Maybe after Christmas, but for now, I’ll have to use my Princess Auto rotary tool, which means making my own tool mount for it. I might make that a CAM learning project for my 3018 toy CNC.

I have various microswitches. I like those RepRap endstops, but it turns out that I only have 3 left, so it probably doesn’t matter, so long as I know what my mounting provisions are, so I can have them ready.

A question about the idlers. My idlers are 14.3mm long and I have no chance to put them in the tracks (F version).

Are my idlers to long or my trucks to small (print issues, …)? How long are the idlers from others?

Now that’s an idea!

Chocolate carving… Mmmmmm …

Oh wow. That’s a mess. You’re so reliable, it is easy to forget that you run the shop out of your house and when stuff happens, it’s just you fixing it, along with the washer, and the laminate, and the printers, and the label printers.

I’m glad you’re doing ok with it. I’m sure people will understand.

About ready to cut my island out on my Lowrider…

I remember the first time that happened to us. Wasn’t that big of a deal, the unfinished basement was right under the washer, water went straight down for the most part. Except the furnace was right under the washer in the basement. Water blew the main board in the furnace, as anyone who has had the misfortune, buying a new one is cheaper than fixing the old. Two count 'em two floods later I was finally smart enough to put a tray under the washer to catch any mishap…

Never could understand why people put laminate in laundry rooms. We have tile in ours. It even slopes to the middle with a drain out the house.

If the wife would have let me, I’d have a drain installed in the middle of the kitchen. How many times have you spilled something where you thought it’d be nice if you could just hose the whole room down?

Every time I clean the bathrooms. Having spent many years in restaurants, it’s one of those solutions that seems like a great idea until you realize how much in your house is NOT resistant to water, like paint, drywall, and cabinets. Then there is the consideration of what amounts to an open drain that needs regular water running through it. Maybe with a cap or something, but it still doesn’t solve the first problem.

Call me crazy but when we renovated our house, i wanted the laundry up on the second floor with the bedrooms, where it belongs. We turned one of 5 bedrooms into a laundry. The washer sits in a 2” pan. No more up and down the stairs with laundry.