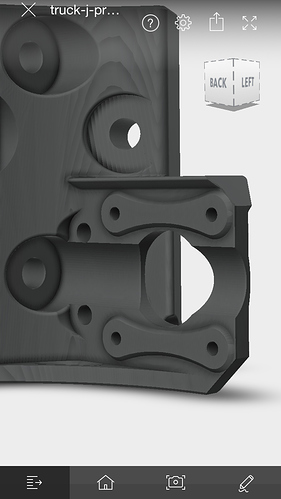

The truck update addressed an issue with some stepper motor mounting screws bottoming out in the stepper by making portions of the mounting area thicker.

The other fix is a washer on the screws.

Damn, had it wrong.  But close.

But close.

Not wrong I think your right to corrected both😀

Hi all. Ryan, I upgraded from the burly to the primo, bought your upgrade kit. I’m using 25.4 stainless for all the rails. My Z rails don’t make contact with the lower 2 bearings. There’s also a slight rocking movement where there shouldn’t be. I’ve also had some looseness in one of the gantry rails, but that could be from a flat spot in my SS tubing, as it got a little better when I switched it out with another rail. Could all this be caused by the misaligned bolt holes? Do you think I should reprint the core? Should I also reprint the updated core z clamps and core clamps. I don’t mind doing the reprints if it will solve the problem. Thanks again for everything.

This is really hard to articulate, without dismissing people’s concerns. But it is so true. You do not need to stay perfectly rigid with an 80kg human pushing it around. It just need to keep a 3mm bit from wandering. From a “support” perspective, people occasionally come in and say their machine is too floppy, or they push things around and see something flex, then want to make that part more rigid. You can’t just say, “It’s fine, stop poking it” because sometimes there is something wrong, and we have made improvements over the years from suggestions like that.

If only it was that well!

I think the misalignment error was on the 25mm, version F (for Fine measurement system)

Twisted Z axis, reassemble using a flat surface as a reference.

The 25.4mm parts should be fine. Try rotating your rail, if it has a flat spot then it is probably more of an oval.

Best to start a new thread for this stuff. Trying to keep this one for Primo updates.

Not gonna start a new thread for this cause its a pretty quick question. Will the 23.5 mm core fit on the 23.5 mm burly? I designed a bunch of parts that for a project I’m working on and they all fit on the burly, but none of them go on the core, and I kind of want the primo core.

No, the gantry rails are going to be off a bit. The only interchangeable part is the Z-Axis/tool mount assembly. The rail spacing on that is unchanged. But the bolts are different, so you have to match the tool mounts to the nut traps.

Kinda. You will lose a ton of build area.

Alrighty. Probably won’t then. Kind of a bummer, I think all the bolts in the burly core are points of failure and I think you recognized that in the Primo core and the Primo core looks pretty cool too.

I both have 3x8 / 3x10 screws and washers instead, so i think i can solve it

I don’t understand this. The only reason I changed it is so many people had issue getting it perpendicular.

Sorry for no update last night it was pretty late. The 23.5mm core and clamps work great, seems that the issue is fixed. I will export the 25mm stl’s and put them back up asap.

I have made a few edits to the 23.5mm parts and they are still printing and I will be fully assembling that version before release so, soon, but not sure when. It looks pretty good so far so fingers crossed.

Huh. I just thought the more joints the more points of failure. Made a mistake and had my endmill skip around in the material recently and the core had a lot of slop after that, and everything had to be retightened. On a core with less joints to tighten it seems less likely to happen, but I have not had the primo core so I’m speaking hypothetically.

You probably need a video of the conduit primo cutting some steel. And then link it to the words, “Oh reaaally!?”. But that can wait until after the release of the parts, I guess.

Well, the Primo core is stiffer. With Burly the force is conveyed somewhat indirectly and traverses multiple parts going from Z to the gantry rails and from a touchy-feely sense it seemed sub-optimal to me. But I try not to second-guess it (not always successfully).

I see plenty of other improvements too. Even if zip-ties were in fact fine, they did in fact generate complaints. Screws could be tightened by jamming a screwdriver in the right place, and the Primo fixes the complaints even if the machine had nothing to fix.

I cut the zip ties on the belt tightening as short as ever possible, while stile having a small tongue to grab it if they needed more tightening. They often scratched my forearms!! Alas, sigh - those days are gone