That looks like steel. Can you tell what it is?

Those are usually 16ga steel.

Please it is possible to tell us a period when the 25mm version will be available?

In Europe its nearly impossible to get a 25,4mm pipe.

And could someone tell me which parts are not affected by the diameter, so i can start printing the remaining parts.

thanks in advance.

25mm is next on the list, but we need some more “normal” folks to build the current version to make sure there’s nothing really stupid that’s going to bite us all in the ass. The only thing that’s not really affected by the diameter is the nut traps, so may as well wait.

are we talking about weeks or month?

or should i build the old version instead?

The old version works great. Ryan is the only one who can say how long, but he’s working on that at the same time he’s running the shop, and shipping parts. Seems like everybody and their brother is ordering a machine right now, which is a good thing, keeps the lights on at v1engineering. Unfortunately that does slow down the cad process.

but i still wonder about the huge differenz between both build because there is a tolerance of +/- 0.4mm in the diameter on a v2a tube.

Hey Jeff,

Tim is right 16ga steel.

I don’t think you can remove 1.6 mm of slop out of any part at the extreme end of play

I had issues with looseness on one of the parts due to a .2mm difference. I know it’s difficult, but it’d be best to wait for the appropriate parts.

There’s quite a few of us that have upgraded to Primo from our Burly with the 1" parts now. We’re running cuts on the machine as fast as we can. I think Ryan wants to make sure the new machine doesn’t have a major flaw before finishing the design for the other sizes.

On the Main Release page he has a list of what needs to take place before he will move on with the next size:

@vicious1 can you assist me on that issue? I can’t seem to get that 2mm difference out, no matter which of the core tension bolts I loosen/tighten.

Please start a new thread so it is easier to keep track of.

Coffee in hand, second email of the day, and GP is cutting steel…this is going to be a great Monday!

Done! I thought I couldn’t create one, turned out I had to go up to the main page to activate the thread button.

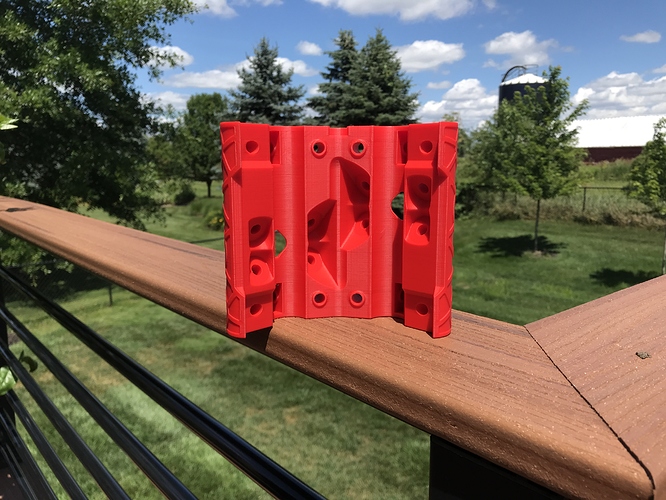

Your control box looks neat.

Yes!

That poor core gets a taste of outside beauty and fresh air, then gets locked down and put to work amid terrible noise and dust for the rest of its life.

Better to have loved and lost…