Curious whether you find Fusion or SolidWorks easier to learn? I’m still trying to find a CAD program I’m most comfortable with.

Rotated how I have it in this picture?

https://www.prusaprinters.org/prints/33165

What is it hitting? Not sure maybe it needs to come off. I have a different router on it right now.

Sorry I guess I still have a page of instructions left. The wire darryl goes on any belt clamp screw. It just gives you a place to fasten wires to. In that dewalt picture I have mine in the back right corner and all my wires are zip tied to it.

Perfect! This was exactly the info I needed. I had my DeWalt with the cable pointing right. And the wire Darryl makes sense now. Except for maybe the name ![]()

The name…Just to appease the monsters that voted to call this version Darryl instead of Primo…I actually got nervous Primo only won by a slim margin

One thing I learned about building my first MPCNC. Make sure all electronics are removable easily without taking anything else apart. Running cables through the holes in the middle seems like a good idea from the start until you need to take one of the trucks off for some reason. I’d either slot them, or do like @jchaager and make sure you have connectors outside the tube you can undo for removing things.

Should totally be called Wire Franks

I’m guessing this was more a request than information for the heathens that voted ![]()

Do you have a time frame for the Wiring page to the instructions? I have been looking daily for it to pop up.

I think that would cut out most of the chatter here about grommets. On the other hand, guess it would be a great learning experience for some just starting to use Fusion360 and other variants.

The wiring is just how to run it through the tubes and such. Actually plugging it into the board is already up.

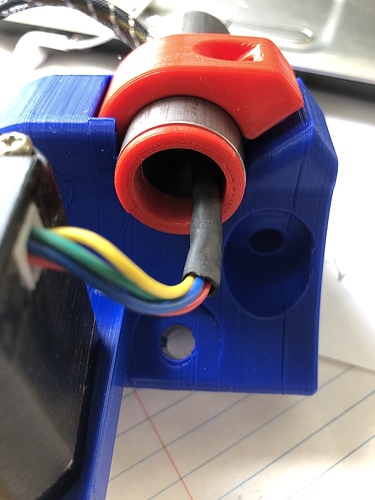

This is what I had in mind and my test grommet:

Not sure if I’m going to keep it or not. It just seems like an easy fix to prevent sharp edges from the tubing cuts from wearing away at the wiring or wiring sleeve.

I made a simple bushing with Freecad. Still have an STL but it is for 3/4 EMT.

. A bit of electrical tape would work just as well.

. A bit of electrical tape would work just as well.

Would this work for tubing?

You might be able to make the 0.875" ID tubing work. With wall thickness of 0.04", you get 0.955". That said, I’m not sure how smooth the outside surface is. The fact that they spec the ID tells me it’s the more controlled dimension. I’m also not sure how CF tubes stand up to the pressure from tensioned bearings and the various clamping forces.

Also, this is like 5x the price of the Jegs tubing others have been getting.

(ETA: Also it looks like we bought out the Jegs 1" tubing supply haha)

My guess is that it would crush too easily. Remember that all the forces are being transferred to the tubing along three points. It’s easy for us to wear flats in SS as it is, and CF is more susceptible to crushing forces than steel.

Weight always seems to come up in conversations, thought it might be worth looking at😃

E.g.:

https://www.jegs.com/i/JEGS/555/35012/10002/-1

The CF tube is 6x more expensive than the above steel tube, which is spec’d for 1in OD with double the wall thickness.

Maybe you could do a hybrid design with CF as just the gantry or just the Z axis rails. Eliminates weight where it matters most.

Yeah, I was leaning toward 1” chrome rod for the base, and something light for the gantry

Or, like they do with arrows- carbon wrapped around a hollow aluminum shaft. In this case, it would a carbon shaft with a thin wear resistant steel wrapper.

Is that why it’s called a wire Darryl?

That’s a bit hard to answer. I first learned CAD on solidworks so it was a bit of a learning curve. I was pretty good at cad when I went to fusion, so it was more of learning where things were located.

Solidworks is expensive, fusion is free (for hobbyists and education). The industry looks like it’s accepting to both, so I would say go with fusion.

Check out NYC CNC on youtube. They do a LOT of fusion work. It’s all geared to making stuff for CNC, but the modeling techniques are all the same