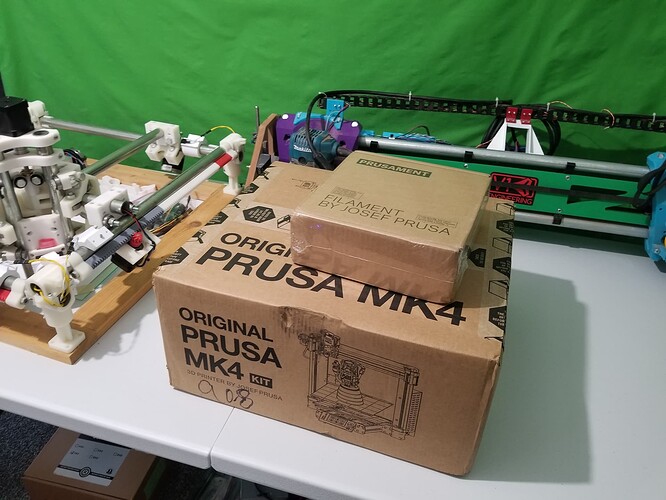

I am not convinced that the parts in that box aren’t going to be used for some extraordinary project that’s not a printer! ![]() I am looking forward to your reports too!

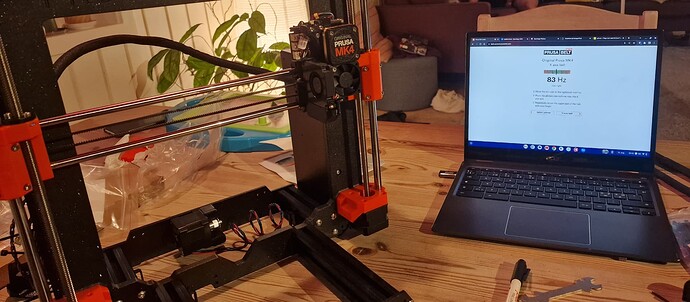

I am looking forward to your reports too! ![]()

Prusa will be stock for the foreseeable future.

As for my previous printer (Anet A8), I don’t have specific plans yet, but there is no telling what loony ideas might come!

MMUA8!

I got the new display yesterday and have been printing a lot with it, no more problems. So it really was a defective display.

Good to hear! I have a super first world problem here… staying at the cabin waiting for a bunch of guests for a great weekend- while knowing that the MK4’s arrived back at home. I guess I should be thankful for both! Also nice to have a project to keep me entertained after the holiday is over.

I knoooow that. You are really happy about the company but really, really want to build that printer/cnc/whatever. ![]()

I’ve been taking all look at the K1 max. Just trying to find some more on them before I dive in. I’m tossing up between the bambu and K1 max

Don’t use a screwing machine they said. And be mindful about the screw length they said.

A friendly reminder to not be too cocky and hurried!

Bolt and nut got super stuck. Had to cut the bearing out with the dremel and print a new part. Good thing I didn’t get rid of the mk3 already!

I just went here to ask you and @jamiek how it’s going. ![]() I have been printing stuff quite a lot because it’s so fun to watch, but now I don’t know what to print. At the moment it’s a Squirtle.

I have been printing stuff quite a lot because it’s so fun to watch, but now I don’t know what to print. At the moment it’s a Squirtle. ![]()

I did all the screws by hand btw… -_- You cheating with the cordless drill. ![]()

I really appreciate this cordless drill! It’s light in the hand, but strong and quick. Bosch GSR 12V-15 FC

But it doesn’t matter if the user is not paying attention!

I have to take assembly step by step… I want to rush it, but it’s weird how the day doesn’t have enough hours! It was a bummer having to print the part, the PETG was really old and humid, so there was a lot of oozing and stringing. As long as it works, I’m glad.

Now I feel really bad. That would make being in a cabin with a bunch of mates look more appealing than assembling a printer!

At this point on erm “other social media platforms”, when people start carrying on about how things don’t fit properly (and in those places it’s never their fault) I point them to the link about post processing of parts.

I didn’t think to do that with you blokes, because… well words like, intelligent, patient, knowledgable, resourceful and the like all come to mind.

But everyone makes mistakes. Prusa’s big one was not to link this document to the instructions for the Mk3, so I guess they haven’t for the 4 either. It’s nothing you don’t know I’m sure, but I certainly didn’t when I was assembling my first printer and it made a HUGE difference.

I am pretty sure they did that for the parts they sold. I didn’t find any supports. ![]()

I just finished the extruder last night, so 5 of 7 parts done I guess. Been a bit distracted hammering on FluidNC.

“Clean the holes by drill bit 8.1 mm (0.3 inch) in the X-end-motor and the X-end-idler marked in the picture for easier insertion of the rods.”

I guess I should’ve gone this way instead of hitting the rods with a hammer to make them fit

… ![]()

![]()

![]()

That’s how I found this document. I hammered one in and thought “that can’t be right”! After just twisting a drill bit in the hole by hand they just fitted perfectly. I am thinking about replacing the bearings before handing it on to my grandson, but am a bit afraid that the disassembly might highlight the error of my ways in a former time! ![]()

That’s pretty slick! I haven’t seen that before.

@vicious1 , you need to step it up and add a belt tensioning page like that for each machine. It’s not like you’re busy or anything. ![]()

Looks neat, love the idea/concept. Just tried https://belt.connect.prusa3d.com/ with my MP3DP and LR3. Wasn’t able to get it to pick up audio frequencies that made sense to me. I keep meaning to try a belt tension gauge.

I dont have a good pitch at all, but I’ve always liked using the tone of the belt as an indication. Not too low and not to high. I guess the length of the belt would be important in this?