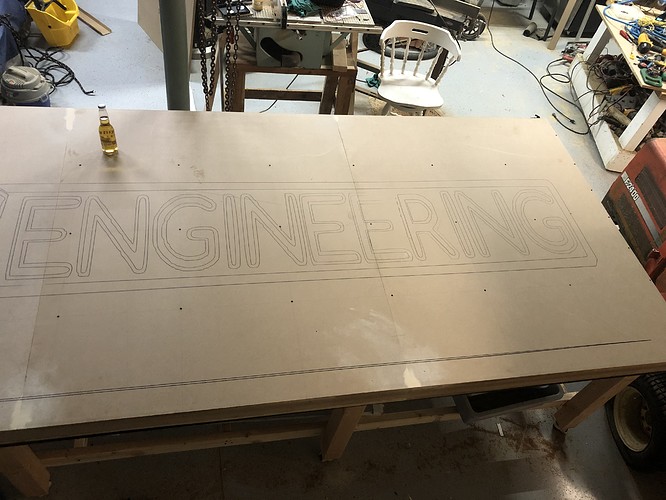

Started the frame today. 5’ x 13’3” will allow for full 4’x12’ aluminum sheets. All top edges ran through jointer for flatness. Lower shelf and leveling casters next. Then a torsion box top.

Can’t wait to see it.

Wow! That will be an awesome machine there! You’re going to be ready to go into production on something

Oof super jealous of a 2 car garage dedicated to workshop duty. Off to a great start and definitely one of the bigger tables here when it’s done.

Thanks. I have never had the will power to put a car in a garage. They always end up filled with tools. After 20yrs my wife doesn’t even ask to put her car in anymore.

This is why the goal for the next house for me (and the fiancée) is that it has the space for, if not already has, an outbuilding for me to put things into

It’s alive! Very happy with it after initial set up. I have a little walk of the gantry in the x axis. I think I can work that out.

Next steps:

Finish dialing in for accuracy and repeatability.

Face the entire table

Mill in 2”x2” squares for a three zone vacuum table.

Varnish table

Face both sides of .5” mdf for 4’x12’ draw through spoil boards

Hey Brian, was wondering where you got your tubeing from. I live close to central PA and 'm just getting started with mine and am having a hard time sourcing it. Thanks!

Metals depot out of Baltimore

I found stainless steel 1 inch / 25.4mm tubing Here

Delivery was quick and packaged well.

Thank you both!