awesome, thanks for responding. Your machine looks amazing, can’t wait to see it running

I’m on the same development path. Started with the 525, then Lowrider2 and then the Primo. Primo was a small one and the first one that I managed to build with enough patience for it to work in the way Ryan designed it. But then an opportunity presented itself and I got two Workbee-clones(1515 with lead screws and 5050 with ball-screws) for ~1000€. That deal included a control box and DeWalt router as well, so no way I was gonna pass up on it, even though there was something fishy.

Well the obvious fishiness was that the 5050 is tiny - 270mm x 270mm working area. The not so obvious fishiness was the 2mm pitch lead screws on the 1515. Holy lead screw whip Batman!

I tried 6mm belts. Speed was great, but the belt-strech was unbelievable. And in the end,I do prefer the non-back-driveable nature of the lead screws.

Now the 1515 has 12mm diameter 6mm pitch leadscrews, hgr15 rails on X and mgn12 rails on Z. It will probably have 100x100x4 aluminum square tube as its X axis and hgr15 rails on Y some day.

The 5050 is on its way to become something else as well. HGR20 rails on X and Y. X-axis will be extended to 800mm by replacing the surprisingly flexy C-beam with 40-series 40x120 extrusion. Probably mgn12 rails on Z on that as well.

V1 machines were the gateway drug to CNC. I wanted a CNC to do projects. Now the CNCs are the project. I guess we all need a way to let the crazy out somehow.

I have been looking at steel beams lately… ![]()

That sweet sweet Young’s modulus…

But the weight, the straightness and corrosion steers me towards aluminum still.

He does it pretty well here, building a gantry grinder. I don’t have time for something like that regrettably. ![]() Maybe some company with a metal mill could make it flat.

Maybe some company with a metal mill could make it flat. ![]()

So I found this after I had started my build. Not sure it would have changed my mind, but it would have been tempting. The build flexibility of extrusion probably would have kept me on my path, but this machine looks pretty beastly: PrintNC V4 | PrintNC Wiki

There’s probably quite a few builds to follow, but I found this guys particularly interesting: https://youtu.be/H9_zK7b9rRs?si=dPd5HPT0KJn6faJ3

I’m hoping that doubling up the c-beam on the gantry the way I did a long with the linear rails gives me the stiffness I’m looking for.

Maximum deflection of a beam is a function of the span in the power of 3.

So if the C beam can be considered a bit noodle-like at 1500mm long…

You have 1/3rd of the deflection since your span looks like around 1000mm

You have the beams doubled and laying in different orientation (better regarding torsion, which seems like the problem to me). In that direction the C beam is 5 times stiffer. And because they are spread out, even more resistance to torsion. I’d guess your build is 3 x 5 x 2 x 4 = 120 times stiffer than my 1515 “Workbee”.

So I didn’t do extensive calculations when designing this …I took more of a “that looks about right” approach, for better or worse.

But I did orient my X axis c-beams the way I did intentionally. I was more concerned with deflection in the x/y directions than z sagging.

They do have a deflection calculator on the openbuilds wiki, and punching in my numbers I should be ok in both directions. I also went with the 1.5kw spindle as opposed to the 2.2kw to save weight on the gantry. It’s actually harder to find the 1.5kw models for decent prices, especially with the er16 collet instead of the er11. I ended up finding this one on Amazon, and to my astonishment, I measured .0003" runout at the spindle taper. I lucked out.

Also you should look at Makerstore heavy cbeam.

Oh wow, very interesting. More expensive, obviously, but it only would have been $120 more for the amount I used. Too late for me on this build, but thanks for sharing!

Those really look good and the price is good as well.

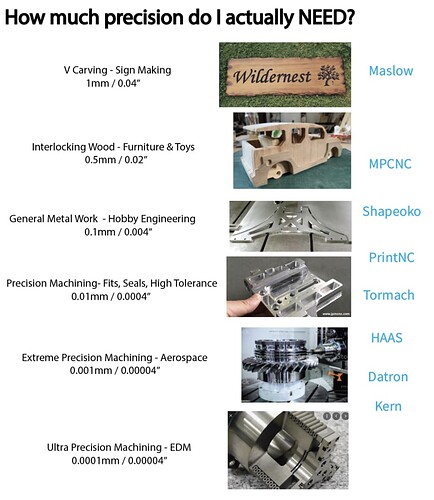

PrintNC shots fired:

0.5mm on an MPCNC. It cleary shows they haven’t built one. ![]()

I dont even think they looked at one

After watching his video I now want one. Pretty sure Nema 17 and belts would still work with that thing. ![]()

Can you please send me a link to that page.

Here it is. I really like the X-Steel-Beam though. Can we have that? ![]()

Oh shit, I didn’t see that. I stumbled across that guys YT page before I ever looked at their home page.

I think the proof is in the pudding with what has been accomplished on this site. They are coming from a place of complete ignorance.

Speaking of a “place of complete ignorance” ![]() , in looking at these types of builds, I’ve been wondering why there aren’t more designs similar to the Lowrider 3 where the beam moves up and down, creating more stability at lower Z-height? Clearly I’m not an engineer, so perhaps this is a spectacularly stupid question. But it seems to me that the machines designed for full sheet goods would benefit, if Z height isn’t a major concern.

, in looking at these types of builds, I’ve been wondering why there aren’t more designs similar to the Lowrider 3 where the beam moves up and down, creating more stability at lower Z-height? Clearly I’m not an engineer, so perhaps this is a spectacularly stupid question. But it seems to me that the machines designed for full sheet goods would benefit, if Z height isn’t a major concern.

I’ve been imagining a design with captured rails, but with Z handled similar to the LR3, even if the beam is C-beam. I’ve just not run across anyone who has talked about it.

Also one of the things I’d like to do. But not enough time. ![]()

IMHO, we should be cheering for everyone in the CNC space. And for the most part, everyone is pretty friendly. For whatever reason PrintNC seems to be the one that isn’t friendly to others. I don’t want to be mean back to them. But it is disappointing.

Always take the high road!

Besides, LR3+ or LR4 or whatever is cooking up in Ryan’s head, be ready for the next step forward…