That is not the point the one with most tools wins🙀

“If a man says he’s going to [finish a project] he’ll do it. There’s no need for his wife to remind him about it every six months.”

My wife is impressed that I’m putting an old laptop to use, as a controller running repetier/cnc.js. She’s claimed that it’ll never get used again, and that we should get rid of it. That was 8 years ago. And now - lo and behold - it’s useful again!

My dad talked to Norm for about an hour before one of his talks at Ohio State way long time ago. 99% of the tools on his show are donated. They get a duplicate for Norm’s personal shop at home. When they build projects, they do it three times. First time to figure everything out, second time the project goes home with him, third time is for the show, and usually gets donated, or auctioned for pbs. For a long time if Norm cut himself, they’d stop production until the cut healed. They don’t do that as much anymore.

Slowly getting along. The Z-assembly was quite tight so I had to sand the holes for way too long. Can someone explain me why PLA is so hard to sand? I felt Like I could have sanded Aluminum better than it.

Also because I didn’t want to sand my leadscrew so long I put it in the drill and had the sandpaper laying on the table. But I might have pushed to hard it wobbles now. Eh. Hope that doesn’t matter too much.

Also best moment of the build. I didn’t have to adjust the lengths of the outer rails because for some reason they were perfect down to a milimeter. I had to measure 3 times because I didn’t believe it.

I also broke 2 drillbits while drilling the conduit. Stainless is hard if you have cheapo drillbits.

Anyway learning quite a lot and I enjoy the process. When I was moving it yesterday for the first time I was super happy. Thanks Ryan for the amazing design. More than once I thought that is amazing. Like the locknut thingis in the rails. Amazing.

I also found out I have to design the holder for the Makita. Didn’t expect it as everything else is so available. But that way I can also contribute a thing to the community.

It’s great fun to build! There are a few mounts for the Makita on thingiverse:

Thanks for the tip. I assumed the makita rt ones will not fit mine but they have the same shaft diameter.

Almost got it running yesterday but then the steppers twisted and I didn’t want to solder again, so I left that one for today. But I hope the crown will be plotted to today.

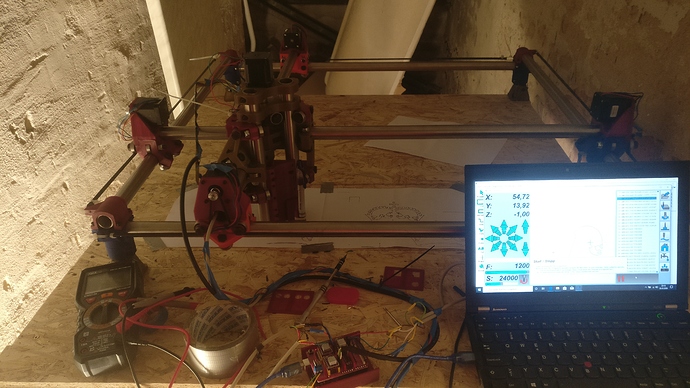

It can draw.

Please ignore the cable Management. I will probably never fix that later. But it draws. It was amazing. And it is pretty square from the first look of things.

Gonna make it dirty tomorrow.

Only one question left. One axis is significantly lourer than the other two. Do you know what the cause could be?

It is terrifying. I checked the vref. It is good about 0.7 V. The only guess I have is to check the wiring. Maybe one spool is not powered propperly.

Yes check that both motors on that axis are powered. If it’s dragging one it can seem like it’s just noisy.

Couldn’t find anything with the motors. The wiring seems to be fine. But now I got the bridges for microstepping and now it is almost gone. It is still louder than the other axis but I guess I will deal with that once I get bored of letting it work. So far I am super happy with the small makita router. I do not think it will be the limiting factor in my build.

Also 600 cm x 600 cm is huge. I guess I will also make it smaller at some point because I cannot think of any project that big :).