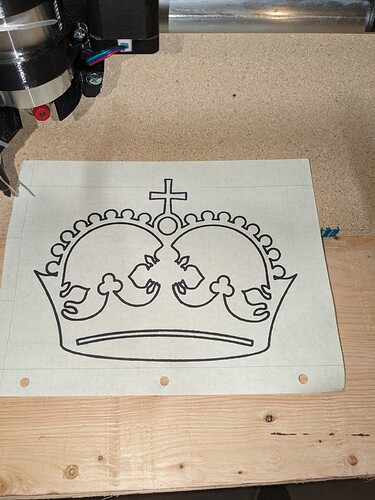

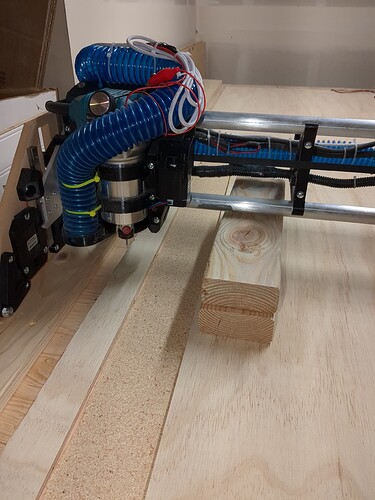

Finally got the machine all tuned in and ran the final test…

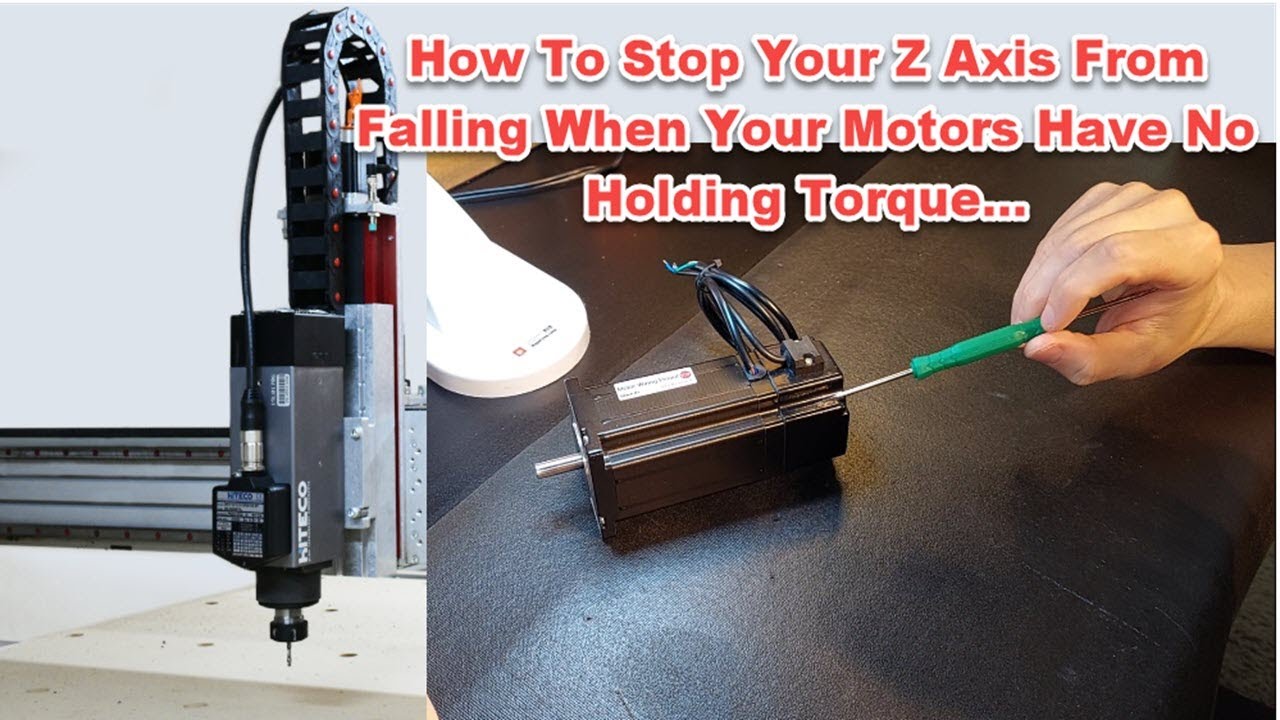

Does anyone have a solution out there for Z Axis Drop (due to weight of makita 700) when the power is cut to the machine?

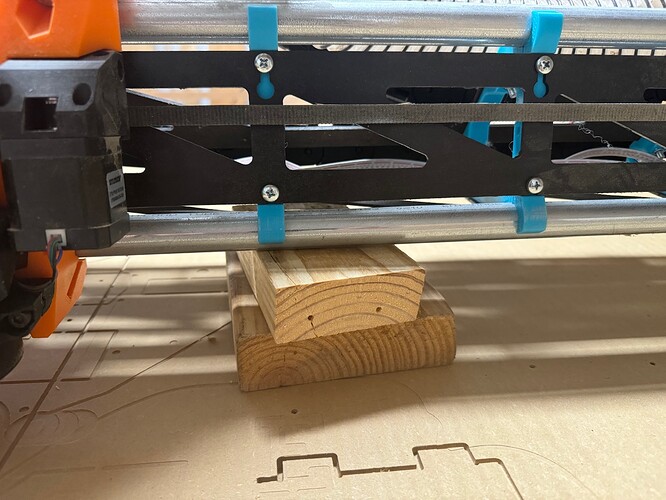

I just slide a couple cutoffs of 2x4 stacked under the rails before I power it off and let it rest on them

From what I am finding out this is quite normal, unless you upgrade your stepper motors to ones that have holding torque when powered down.

For 10x the cost, I will stick with my 2x4s lol

I like your idea more and more after looking into the cost of these

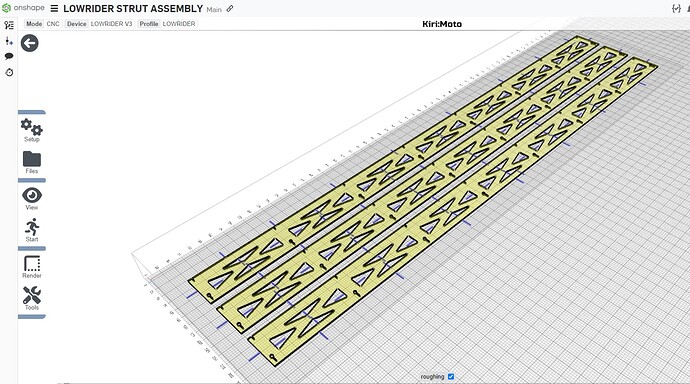

Using Kiri:moto to make the strut plates. Onshape has an integrated plug in for Kiri:moto making it super streamline…

playing around with tab placement

So I have a probe set up, it functions as expected. The probe command on the FluidNC WebUI works as expected as well, but…

I have my probe height entered (14mm)

I have my retract distance set to 5mm.

I home the machine, move to my intended 000 and set. Then It probes as expected.

However when I run the program, the program is running high in Z. And I am unsure if it is high by 5mm, 14mm, or 19mm. I guess I could measure, but would really like to understand what step I am missing. I’m assuming (first mistake) that the probe is a macro command, and should set the proper 000, after probing, before I run my program, is that now the case?

I have a similar thing. I still haven’t set up Z endstops, so I have 3 layers of 3/4" plywood together as hard stops to start the steppers at the same level on both ends.