I started to develop a desire for CNC and after accidentally watching an old MPCNC build video on youtube, it was love at first sight. So, I started my build ASAP hopefully trying to learn as much as possible in the process.

I decided to go with a 24"x18"x4" build area, since I’m more interested in milling small hard wood pieces, acrylic and aluminium. I already sourced 1 x 0.065 inch SS tubes in the search for better rigidity.

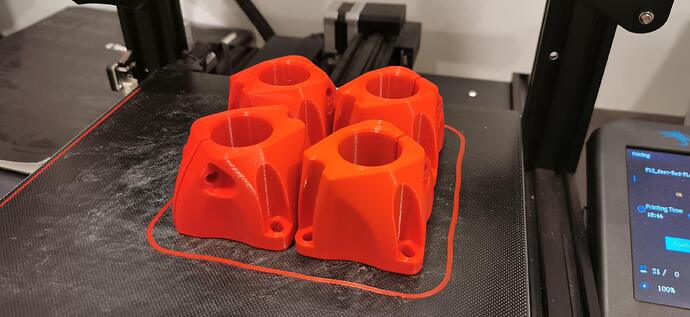

For the 3D prints, after a little research, I decided to use Carbon Fiber PLA because of its higher stiffness at low prices (Please use this thread to discuss the subject in more depth). Despite all the comments on how hard this material could be to print, the Ender 3 V2 is doing an excellent job and after more than 113 hrs of printing (still not finished), it still haven’t failed so far. For being my first experience with this material, I’m quite impressed with the results.

I’ll look forward to read your comments.

It looks really good!

I also printed my Primo wig CF PLA, as a matter fact almost all my prints are CF PLA.

That is going to be an impressive machine!

This is how the project is going. After 228 hours and 2.8+ kg of filament, I finished printing the basics components. For increased rigidity, I used a quite high infill for all parts (+55%, 70 for the core), gyroid pattern and up to 8 layers of wall depending on the geometry. Since I ran out CF-PLA, I printed the rest of parts in PLA+ that I found cheap in a local store. I’m very happy with the results so far. Please let me know your thoughts.

Very sharp looking prints! I love the surface finish that you get with that CF PLA.

Believe it or not, this is my first experience with CF-PLA, also my first experience with the Ender 3 V2. I’m very pleased with the results

You are either supernaturally lucky or very conscientious about research and following the recipe.

Either way, good on ya!