I find myself in a dilemma where I have build a jukebox casing I made from 20mm ply with my MPCNC and now need some finer detail beadings around the Opal Perspex which I am not able to find as a ready made off the shelf item. I have set the front forward by 100mm and the perspex is cut to fit the curve at the top. This leaves me with an ugly edge where the bendy ply sits on top of the ply form. I need a trim to follow the radius of the curve. 15mm x 15mm deep approx 5mm thick

I made a prototype from ply but want something a bit more classy.

Why is it that when ever I need to print something, my bed size is always too small and I end up having to break the item up into pieces? None of my 3d printers can handle anything over 300mm. For this, breaking it up into pieces is not an option, I need it to look right. My OCD

My gut is leading me to consider 3d printing the beadings as cnc tends to break them apart being so fine.

Trouble is that I would need a bed size of say 700mm long. The width I don’t think is an issue as the curve is such that it can fit inside 200mm width.

As this is a fairly small demand project I dont want to throw too much money at it so i was considering building a modified version of the MP3DP V1/2 with an extended bed.

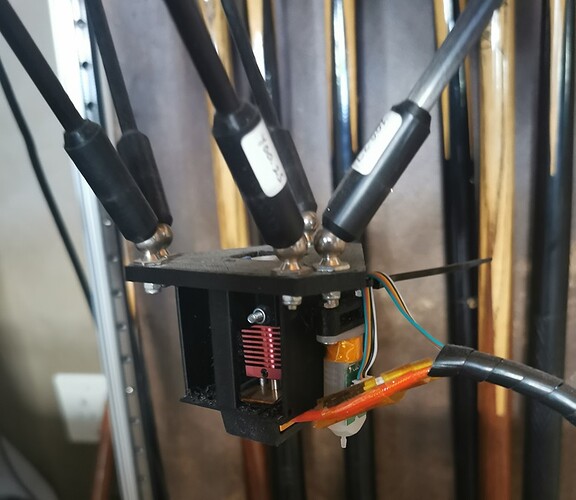

Is that my best solution or should I consider a smaller version of the MPCNC but with a print head?

I have loads of projects that have been build and disassembled so I have lots of bits to hand including extruders steppers etc. Which would be the most cost effective method to achieve this goal?

I am considering the MP3DP version 1 which is a nice simple design that would lend itself to an extended bed. I did build a 400x400 multi color Corexy which I considered to use a similar design but its a lot more work than I was hoping for for a small project.

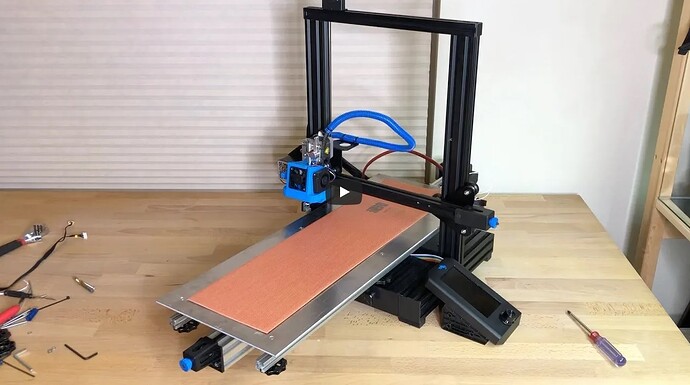

I quite like the idea of a printer along the lines of this one I saw on youtube

Anyone got any ideas? I do have a really old Wanhao i3 V2 that I could perhaps try modifying but from my research it does not seem to be very highly regarded as a model for modification. I know Jeffeb3 had one of the early versions and did not think it was a great starting point. I would like to include auto bed levelling obviously with such a long bed.

Has anyone any experience in building something of this nature. I dont want to go with a huge 700x700 as that is just too cumbersome especially when it comes to heated beds. I can get 200x 300 silicon beds at a reasonable price so was considering using those in tandem.

Any ideas appreciated but my gut is to go with something similar to the MP3dp v1/2.