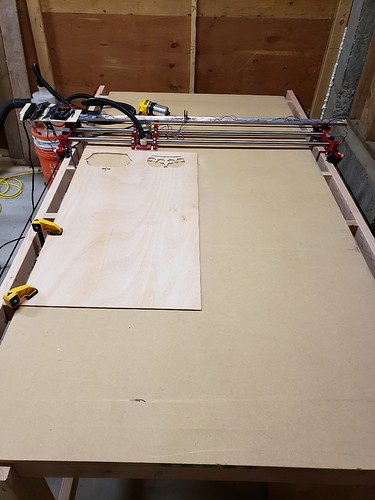

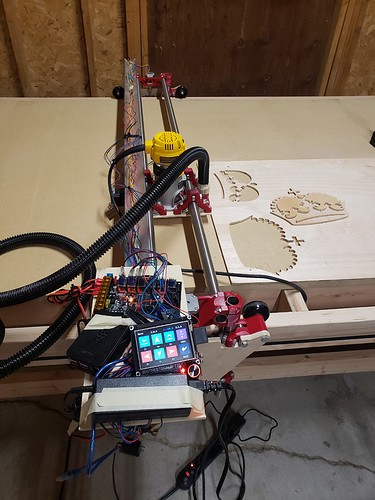

After a lot of reading, YouTube videos, planning, and forum lurking, I finally built my Lowrider. I ordered the basic kit from Ryan with the SKR Pro 1.2, printed the parts on my Ender 5 Pro, and cut out the wood parts with my jigsaw. The 3d printed parts and the kit were perfect but my hand-cutting skills needed a lot of work with a file and sandpaper to get everything to fit in where it needed to go. I also learned a lot about firmware on both the SKR and the screen. The default firmware did sorta work but it limited me to a 200x200 build area and the screen was adding in some g-code that disabled steppers and plunged a sharpie about an inch into my pink foam board (I’m really glad I went with that first instead of diving in with a router!). The forums were very helpful and I wanted to give a shout out to Ryan and his team for making an amazing CNC that’s customizable and affordable!

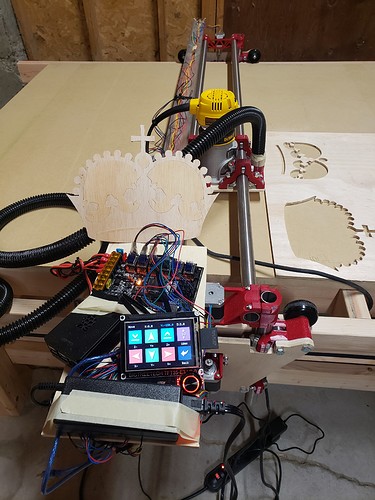

After finally getting things working I decided to try making a fancier version of the crown with the pieces inlaid. I had some 1/4" plywood scrap that was reddish on one side and white on the other and I think it came out pretty good. Now I’m working on figuring out how to do a good tool change for some engraving work to use the endmill to cut down the larger areas and not spend hours waiting for the v-bit to flatten it out.