Hello, and good morning, fellow makers!

I’m in process of making a laser enclosure, and I have the wherewithall (parts in hand, for most of what is needed) to give it Z-up & Z-down buttons for raising and lowering a cut bed, independently of the control board. My big 100w CO2 laser has these kinds of buttons, and I find it tremendously convenient and a wonderful feature. The buttons don’t raise or lower the laser gantry, but rather the bed.

However, I need tips/advice for how to wire that to happen.

My rudimentary thoughts are: the stepper is DC, so I need a way to get DC power to it, whereas the incoming power is AC. Also, my general impression is that one of the two switches would complete a circuit on one of the wires (but which?) and the other of the two switches would complete a circuit on another one of the wires (but which?).

Finally, I have no idea how the existing Z system on my big C02 laser manages to keep the bed in position even while the power is turned off. What keeps it from falling down? Is it just friction because all the lead screws? Is there some kind of ratchet system?

I would surely appreciate any help and advice anyone can give. Thank you!

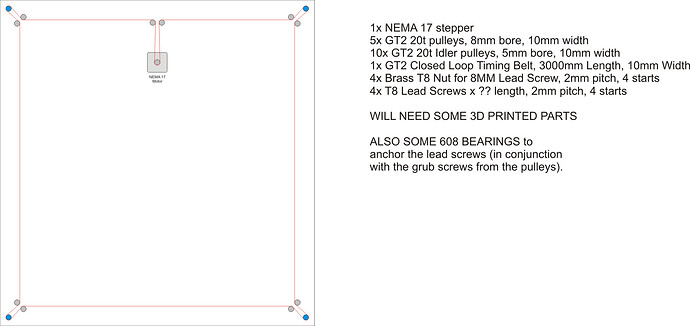

PS: in the diagram below, the blue dots represent lead screws (my plan is for T8 lead screws, 8mm diameter, 2mm pitch, 4 starts), and the red line represents a 3000 mm long GT2 belt, that is 10mm wide. The corner pulleys have teeth and grub screws, and the two “near” idlers for each are smooth. I welcome advice if this seems unworkable.

PPS: In case I get advice that a NEMA 17 is not big enough, I have a much bigger stepper I could use. I cannot remember if it is a NEMA 23 or even larger, but I think it is a NEMA 23.