My wife says that looks like a cell tower!

I saw that one and someone asked about the ATC and they said only available with the purchase of the machine.

While I do think the machine is very nice, I think the bigger product is the ATC. Maybe it’s time to take a look at them see if we can make our own.

A V1 ATC…. Hell yeah!!! I fully support this message!!

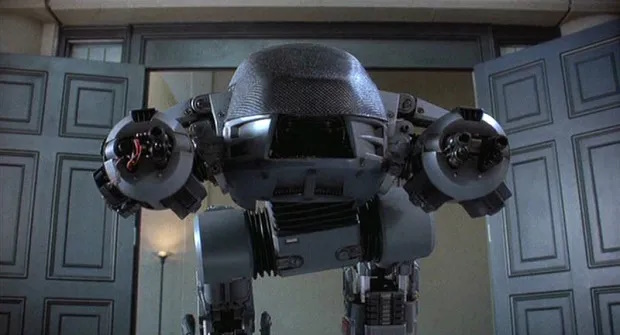

Great idea! Give the murder-bots dual rotating gatling endmills! What could possibly go wrong?!?

So check this out. So simple it is crazy! For what i do with my cnc i do not need a super tight collet! Think someone here could do a prototype?? https://youtu.be/74N3TkCJ7iQ

That is a two year old video, I have only just seen a few systems like that about to get released. I am very interested in it…you need to have reverse though.

Well, I was coming to say Marius Hornberger made one that didn’t require the spindle to go in reverse to drop the tool…

but Discourse stopped me and said it was already posted in this thread…

Indeed. It’s like dark magic … LOL

Well that ATC is off the shelf and really really expensive, and still requires the same spindle I think. There are three companies selling versions of the self threading versions that I have seen. I am interested for sure, but I am waiting for the spindle Barry showed me to come back in stock.

Speaking of spindles…I got news coming soon.

I hope it’s stupendous glorious news. My new shop dogs are just waiting for a challenge😍

Great. 3D printed spindles. Can’t wait to see the tolerances required for that… Too bad the heat of FDM printing likely de-magnetizes any ferrous material. Could be interesting to print your magnets right into your models with some sort of MMU setup.

You are always thinking creatively toward new, affordable options, and we appreciate that!

There are a few BLDC spindles out there, made with all sorts of RC brushless motors

Usuakky they do require at least one mount milled in aluminium, rather than relying on a 3d printed support

I noticed the date. First time i had seen it. Reverse is a challenge, but if there was a group to overcome challenges it is here!!!

Let me guess: You are going to include a pause in the gcode of the core, then the v1 spindle is going to be inserted and encased in your design. Then my v1 printer fails and I have to cut it out using my v1 circular saw, going to bed sadly into my v1 bed with sandified patterns.

Geez… you forgot the V1 sander… lol

That machine must be bolted to that table. I also want to see it use that 3" facing mill. I can’t imagine it takes very deep cuts with such a large cutter.