man oh man, that thing really binds at certain points!

cute though.

Idk if its really binding or if its that he has weight in just 2 of the carriages and none on the other 3. It seems to line up when its starts bringing that weight back up. If he had equal weight on all of the carriages I don’t think it would do that.

the weight is most likely correct, never thought about it.

Things need to be stepper controlled. That way you can control where it rotates to. “Alexa, where are the 5” quarter twenties?"

Cute. Look forward to seeing what a resourceful community with CNCs, and 3D Printers comes up with ![]()

Bonus points for making a flying pick find 'n place, that doubles up as a meat grinder …

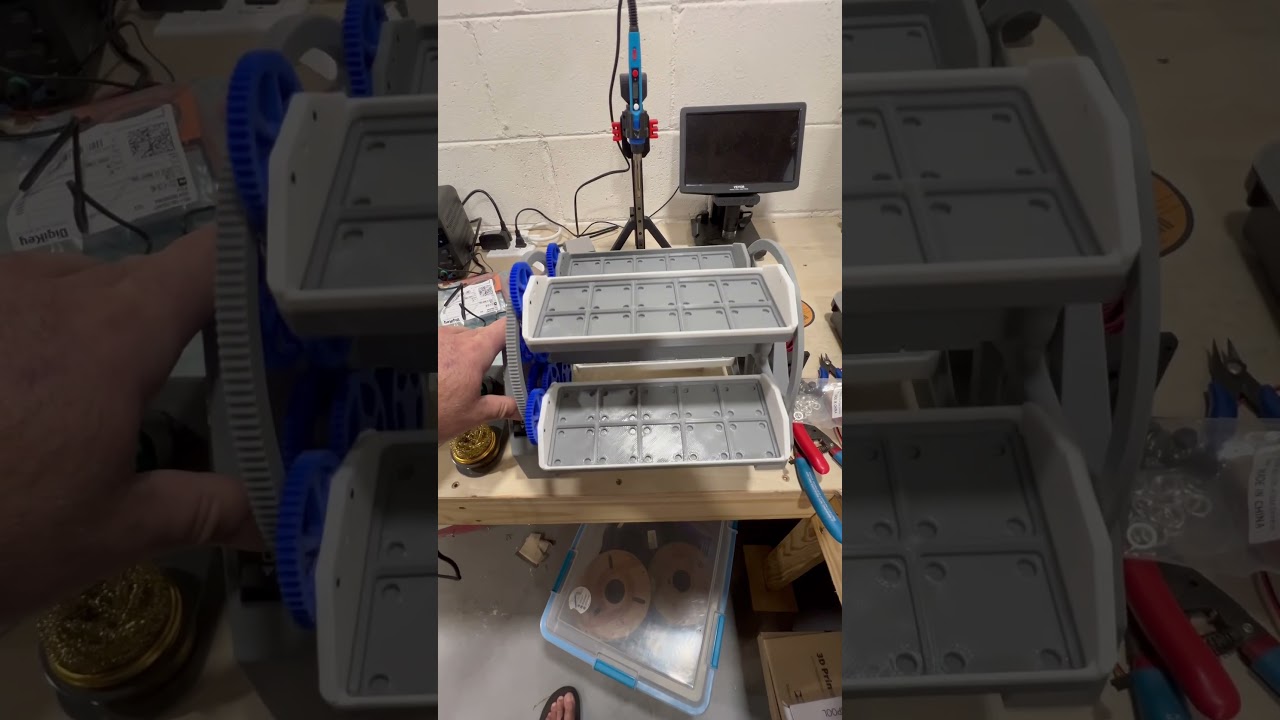

I still have more bins to print. Using @azab2c OpenSCAD to generate the boxes. Works REAL nice! I do wish I had left the labels off of the 1 unit boxes though. Will probably change that on the rest. Got almost enough parts to build a second one minus the motor and printed parts…

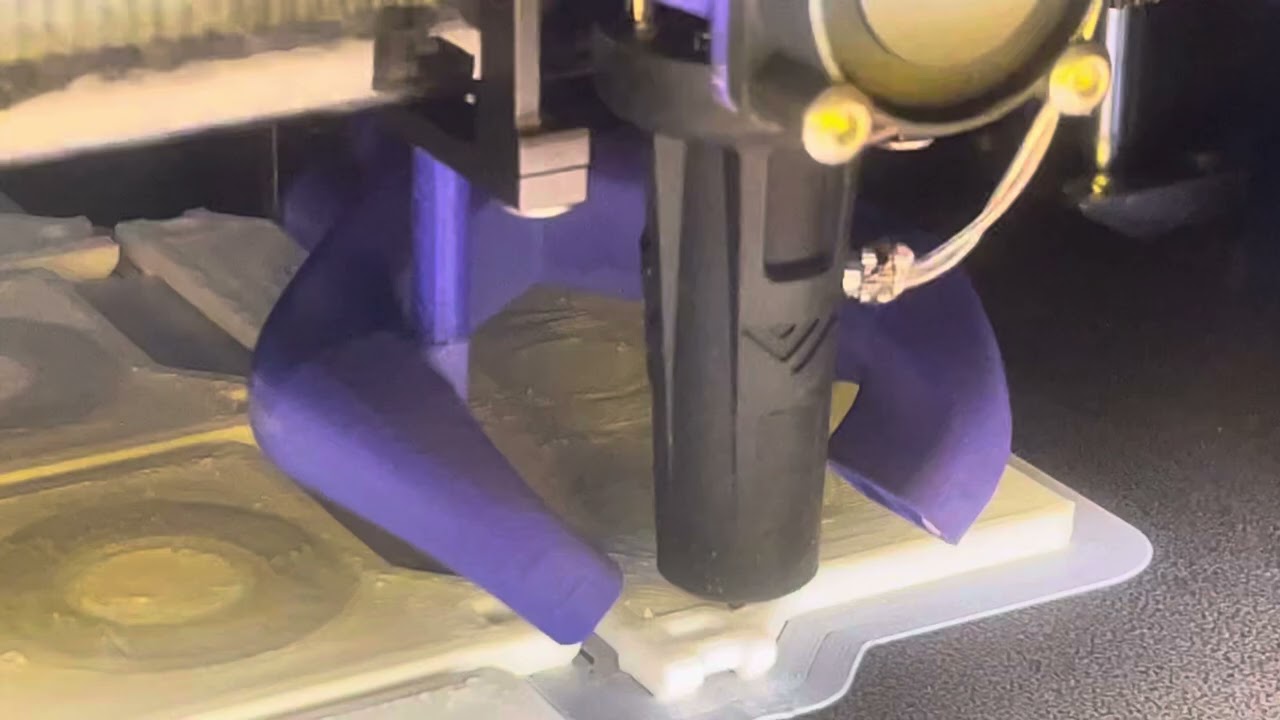

I need to take the “double” gears back off and sand the mating surfaces down a little more and see if I can tighten them up just a little bit. Every once in a while one will catch on the side. He should have put a decent chamfer on that edge so they wouldn’t catch. But so far its just been a little bump, nothing that stops it.

There is a bunch of room in the side where the motor is. Already stand off for a Pi and something else (cant remember) so people can make it run similar to that.

Damn Jonathan, you managed to make this neat project and mostly print LR4 RC3 parts already ![]()

Man, I wish I’d done something that cool. Looks like @jamiek put together an online Gridfinity configurator at https://vector76.github.io/Web_OpenSCAD_Customizer/gridfinity_bins.html, that uses the web assembly port of OpenScad ( C++ with QT UI ). Multiple neat things right there.

LOL I started printing this as soon as I posted the link/video here. I was just waiting on parts. One nice thing about having multiple printers. Kept the V4 and V5 open for Beta stuff. Although the V4 messed up and now I get to disassemble an extruder at some point today ![]()

Oh! My bad @jamiek! I just assumed @azab2c had made it since I stole it from his Github ![]()

I hadn’t ever seen the website version of the Openscad stuff until 2-3 days ago. That’s cool!! And works awesome! I was using one I downloaded and opened on my computer this morning. Great job @jamiek

I like the gridfinity caurosel, however, the cost of the bearings is pretty high.

Where would you start if you wanted to design a 3d printed “bearing” that would suffice in the caurosel??

Look at print-in-place planetary gears. They can be used as bearings and do a reasonably good job of it, though printer resolutions often make them somewhat large.

Ok. The gridfinity carousel uses 20 pieces of 683zz bearings. The 683zz seems like a quite small bearing.

Yeah, which basically means that you will need a basic bushing instead. This isn’t bad if you have a smooth rod, but isn’t easily workable if you have screws as axles, and I suspect that the size means M3 screws, so…

Edit: 1/8" smooth rod isn’t too expensive (here. Maybe 3mm rod elsewhere?) If you make a capped bushing and open up the screw holes to the 1/8" size plus tolerance, it may be possible to use small cut pieces of rod. Even cheaper, small cut sections of something commonly available like a coat hangar, or baling wire could be made to serve.

Super cool looking. Now I’m thinking about a pi with an inventory system, and maybe a microphone?

“I need an M5 x 16”

Whirr…

There it is!

Just kidding - super cool use of Gridfinity.

LOL Yeah you could for sure do some cool stuff with it if you have the time and know how to set it up. I honestly just thought it was a cool design and wanted to share it here. I didn’t even know it was a thing until 5 min before my original post about it ![]()

The screws used are M3. I will try to print a bushing and insert a 3mm brass rod into it.

I have a lot of 608 bearings, would a 608 bearing on the outside of the wheel work?

What speeds do you consider “fast” ?