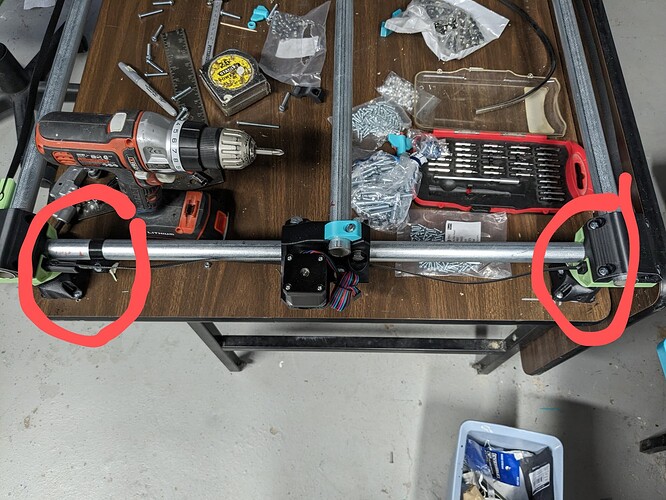

I cut my Y axis belts too short. At full tension, they’re not going to slide all the way into the tensioner slots. Could I proceed to screw them in with longer screws to get them to tension, or should I just take the L and buy another couple meters of belt? If I proceed, I’d be able to let the tensioners behind the end stops out a little more to let them fully fit into the far ends.

So long as it won’t foul the trucks I don’t think longer bolts are a problem if you already have them. I’d probably just buy more belt since it’s so cheap.

It’s mostly impatience and not wanting to take apart the trucks to re-do the belt. I should hopefully be able to find a few really long M5 screws in the meantime.