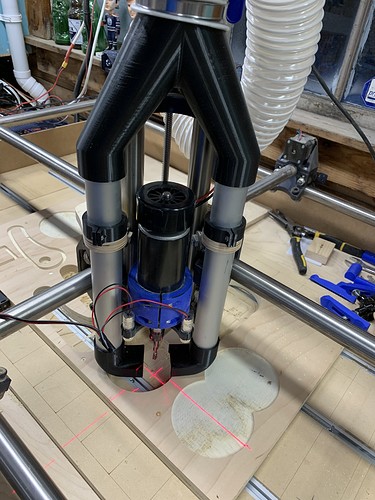

5 printed pieces, plus one cut out of plywood (could be printed as well, but I could cut a piece much faster than I could print one). Dust boots at the bottom still a work in progress, but it seems to be capturing a lot of the mess. Haven’t tried it with MDF yet, though.

Shop-vac is connected to an IOT relay, so it turns on/off automagically. The relay also drives my air assist when using the laser.

Used 1.25" aluminum tubing from Home Depot, and 2.5" dust hose from Amazon.

https://www.homedepot.ca/product/paulin-1-1-4-x-36-inch-aluminum-round-tubing/1000163850

Shown with cross-hair lasers on, just making sure there was no interference

Dust boots swivel out of the way, if needed, or can be easily removed. Whole dust collector assembly removes easily without tools when switching to laser.

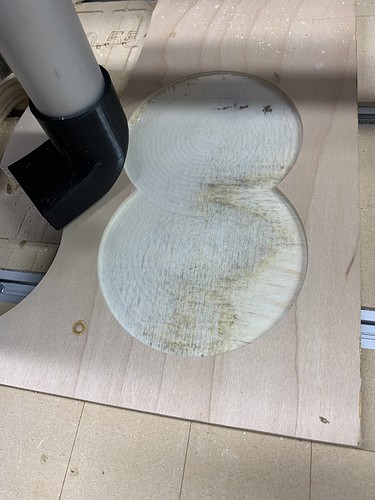

Vacuumed before doing the bottom circle. 3mm deep, 100mm diameter circle. Not much dust or chips escaped, but might try to close off the opening some more with tighter fitting boots. I like being able to see the cut, though. This is the “after” cut pic, with no additional cleanup.

Underside of boot

Did a loft in Fusion between the pipe and the front inlet, using a spline to get the right shape, and then just cut off the bottom. Might try to extend the top and one side of the boot, so it will get a better capture.