Can you solder? If you can, solder the wires onto the endstop switches.

That may be what I do I am pretty good at soldering. That way I know there is continuity for sure thanks

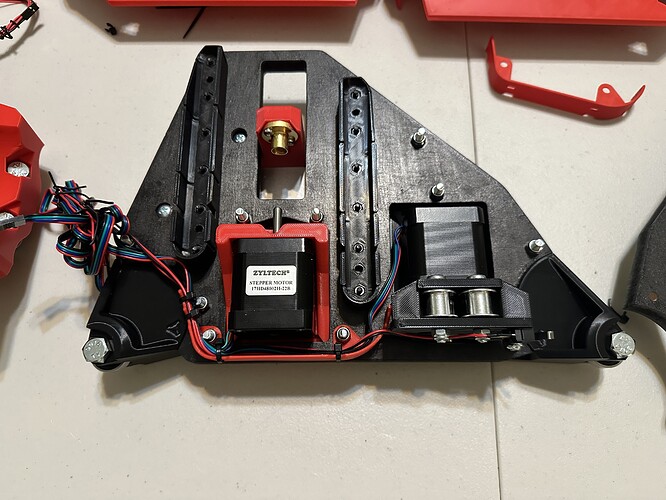

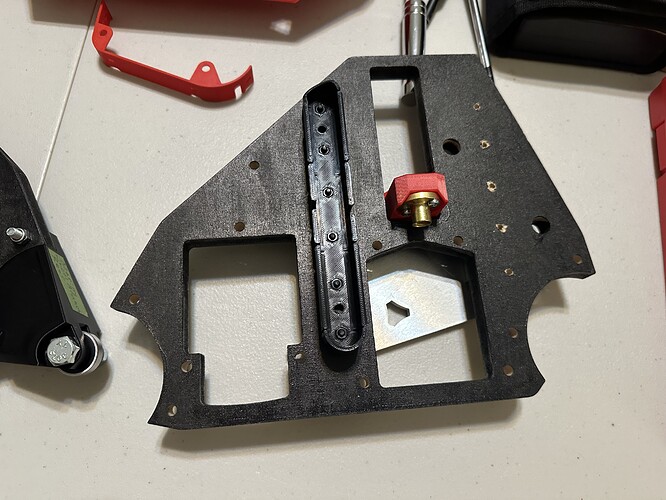

Got allot done tonight really satisfied with the progress. I took Dreyfus advice and soldered all the end stops directly to the micro switch’s so crossing my fingers that it works now. Thanks for everyone’s help and encouragement already in this build thank you. I feel like another really good day and I will have it together ready to take to the garage(that is when I can ever clean my garage out).

Looking good!!

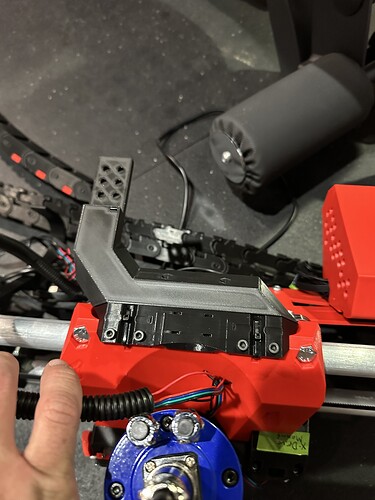

She’s on her own two feet lol big progress today not to run the belt for the core and wire it up and see if my solder job did the trick.

That’s a fine looking machine!

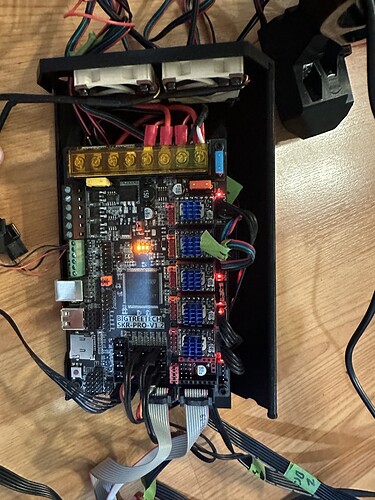

It lives. I was able to home all the axis and movement seems smooth. Now I just need to mount it and give it a real test so I can get the table built and do some major wire management.

Z and Y seem to be homing well. I do notice after the end stops activate I can hear a slight hum still from the stepper motor not sure if this is normal or something going on. Anyway onto finding time to clean the garage and get to building a temp table for the struts and then the OCD task of wire management

Make sure you check that router to make sure it doesn’t have the RPM defect. I guess it’s somewhat common for them to have unexpected fluctuating RPMs. I ordered one off eBay that had that exact problem and had to send it back. Mine exhibited the issue right away when turning it on and adjusting the dial, but some don’t show it for 5-10 min.

That is very good to know is it a very noticeable change.

Update…Of course my luck I am dealing with the same issue have started the return process and attempting to contact another seller to see if the same issue occurs on the ones they are offering.

So I have been very lucky the seller I got the router from ebay stated that he has sold allot of the kobalt routers and never had one have the issue. So I sent him a video and apparently he found the post on here about there being an issue sometimes out of box and is going to refund my purchase. So I have a question in my quest for an ER-11 collet system for versatility I located this Makita clone from carbide 3d or one from openbuilds. My question is has anyone used this particular router to know if I print the Makita mount will this one fit or am I going to have to look into making a new print. I am set on the ER-11 because even though they are cheap when I purchased that Kobalt unaware of the issues I also purchased ER-11 collets.

or

Well, the Openbuilds one specifies a 65mm body, so that part will fit. In the LR core it should be OK, so long as you can find an orientation that lets the head drop in, but looks fine.

Just joined the forum looking forward to some interesting ideas and projects. I would like to engrave the instrument panel on my Homebuilt Bearhawk with all the lettering, using the Low rider CNC 90% done 90% to go.

Looks amazing Like the color combo

Hey George, welcome to the forums.

I’d recommend you start your own build thread, it’s fun! ![]()

You can do cabinets on a smaller machine, just cut the material down and cut fewer pieces at once.

I use the bauer makita clone from harbor freight.

Been waiting on a few parts and after allot of thinking and measuring I decided to go with a water cooled spindle. It looks amazing and can’t wait to get it running. Thank you Doug Joseph for your amazing drag chain design I was going to buy the chain but like the idea of being able to fix and modify on a moments notice and not have to have my machine once up and running. Now onto measuring the wire and get a cable to run the machine with the VFD.