Hi there

I ran into some issues that I can not seem to resolve, hope any of you can point me in the right direction. I have cut like 100´s of items in 15mm thick Poplar Multiplex without issues.

Recently I swapped my PC and reinstalled my tools like Fusion 360, ESTLCAM, etc.

At the same time, as I could not find 15mm A grade poplar multiplex, I bought 18mm instead.

Since then things went wrong. No matter what I do the cut fails as the machine wanders of, or the bit starts to burn. Waisted some serious amount of wood but still haven´t found what I do wrong.

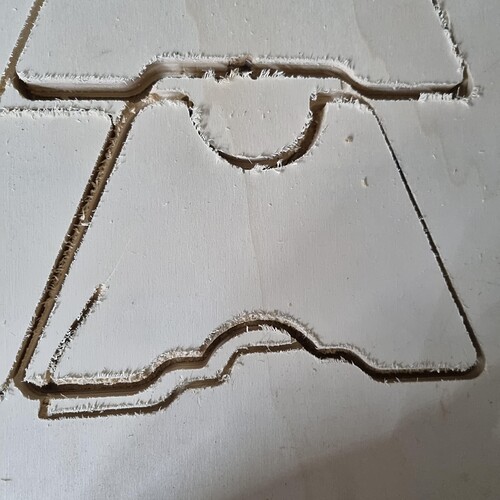

Some examples;

a 3mm bit (from the tools I have used since the beginning), at speed dail 2, it burns the edges as you can see. This cut is stil “ok”

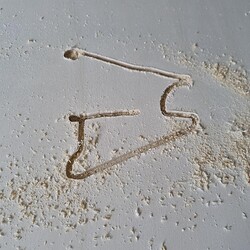

same tools, suddenly it wanders of:

same tool, wanders of again:

One cut went well, the next one wanders of again as you can see

I just bought 2 new bits at Sorotec (single flute, 6mm 22mm DOC).

The bit started to burn, so dailed back to 1,5 and after some passes it started to wander of again, so increased speed dial but it jammed anyway (and burned once again)

Now for my settings, I always used a cutting feed of 15mm/s, 3mm/s Z speed at 3 - 5mm DoC with a 3mm flat end mill (single flute). The same settings applied for my new 6mm single flute bits.

I ´ve tried so far slowing down, gearing up, changing the router speed… start to wonder if something went wrong with my LR setup.