What is the workarea?

Ohman. He showed up after i left!!! Well hopefully another time!! I am home now and had a blast!

So, while at MRRF I was introduced to Clone Hero as well. There were 2 booths running it. They 3d printed guitars. Just doing research on it, they use and arduino, pi pico, or a bust controller and 3d print the body. Looks like the switches etc. can add up though. Some of them were really playing those things!

Sorry I missed you! I was a few hours behind when I had hoped to be here.

The presenter’s overloaded fresh eyeballs only noticed plotter stuff ![]()

I like the setup, looks like a interesting/fun event.

I so wish I was there!!! Everything looks amazing !!

Once again!! Work got in the way…

Sorry i tookoff. Old man syndrome. At noon I sat there and just could not take it anymore. All the talking and still a 4 hour drive home. Enjoy!

Okay, it was a Rad trip for me. Sitting at the airport now. Sorry I didn’t get to hang with the crew as much. I kept getting pulled away or stuck for a long time. That being said I had a lot of amazing conversations. With a lot of fun people.

Lightburn is soon to release a CAM beta, missing a few key features but they are literally next in line for dev and will be there eventually. They are also having a show and a vendor fair of there own in a few months. If any of you are interested it looks like it could be real cool and I will consider going.

One of our own is launching his own CNC kit. I’ll share some more details when we get a few more details. His first alpha build looked promising.

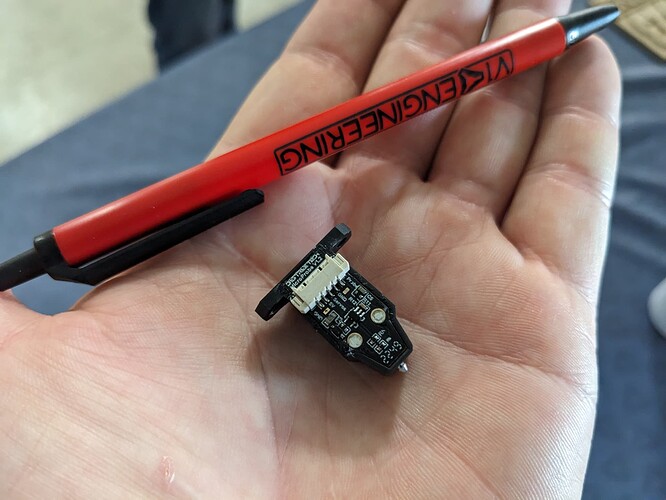

BTT ultralight extruder is as sexy as an extruder can possibly get. They took it as far as using aluminum screws where possible to lower moving mass…I want one. The touch probe they have is freaking tiny, the pics they do not represent it well.

Voron Crew was represented very well again, not quite as many as Colorado but this is the DIY Mecca, so understandable.

I did take a ton of pictures this time.

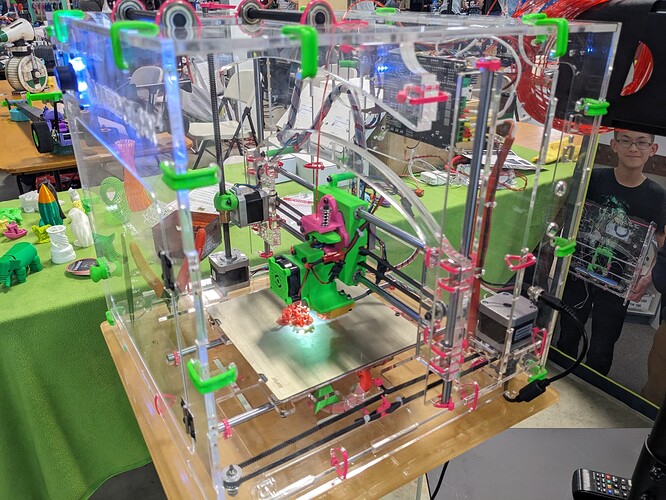

Jellybox was there with a new version of the educational printer. If any of you happen to be involved with any schools or school districts that are interested in an intro into 3d printing they have several programs in fill swing and I can say it pretty amazing what they are doing.

More to come when I get home.

Interesting!! Lightburn has some decent features that I miss in estlcam and other tools. Curious about this one.

The inlays on that board were AMAZING.

I use lightburn for my laser. Will That be a separate product or functionality built into what I already own? Do you know where the vendor fair will be?

I asked that question, they said 2 different, but he was the developer so we can hope he was wrong!

I really like the option to change the size of cutouts and finger joints on the fly. I really thought about buying it just for this feature. ![]()

See the CNC going on in the vid…sneaky.

Currently, the interface is nearly Identical, backend had a massive overhual. Most if not all devs are working on it currently so fingers crossed we get a beta soon. I was told the plan includes all the features I could want in a CAM package, plus a pretty robust vector drawing tool package with filters, they do want to include some 2D to 3D “filters” that allow you to make fun stuff easily with say a logo DXF or something. Lots of vector tools.

Two separate packages laser and CAM, but the CAM side will include some basic Laser stuff so a multi tool type project would be easy (I want to 3D carve and draw on that, easily). They said similar price as the laser package. Sounds like for use and how we use lasers this might cover all our bases. I didn’t ask but it would be cool if the camera features they have on the laser side transfer over as well, it lets you position objects on your work surface very easily. WE talked several times for more than an hour. There is a lot to cover.

All the devs are actually DIY CNC builders before they ever even touched lasers so I think we are in good hands. I saw some of their builds from when I just started to really know what a CNC was let alone think I could ever own one, or DIY one. And the founder is a prolific DIYer, with a wide range of scope.

Oh, there is so much functionality built in. I didn’t know the half of it. The laser program even has a super basic “nesting” type feature that moves all shapes to the left to save material if you are cutting things out. It also has an export/import to a proper nesting program… ![]() Already in the laser program. Tons of shortcuts and features.

Already in the laser program. Tons of shortcuts and features.

Ohhhh. That is my birthday and i already took the time off!! Is it free?? I need to go check that out. Is it on their webpage??