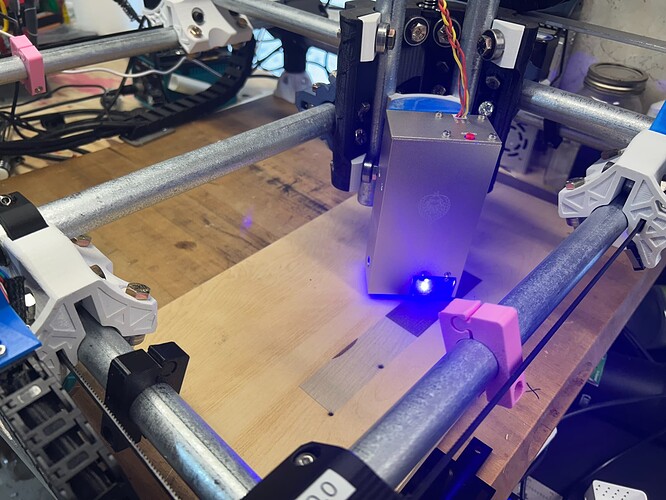

Well after some ups and downs, I have my MPCNC on Klipper running great.

Mellow Fly D5 Board, Orange Pi Zero 3W Host

Aenbuslm 10W(optical) Laser

I have a mount for my Craftsman 1hp router and a small mount for a 775 small spindle too.

Getting to this point was a journey, but I think I can now help anyone else looking to run Klipper on a MPCNC. No special versions needed, I am running plain stock Klipper.

This is great - have you made special macros to make this work?

What are you driving it with on your Orange Pi?

Currently have a Marlin build with Laser but considering re-doing with Klipper. I need to update my raspi and thought I might do this at the same time.

Are your config files posted anywhere or are you willing to share?

What’s your general scheme for running gcode? Do you have separate macros for each G or M code?

I edited the marlin post processor in estlcam for klipper and took out the leading zeros in the g commands. G01 became G1 for example and that helped.

Still have not gotten the probe command to zero the z axis though dual endstops work fine. Klipper on the mpcnc and on the lowrider works fine.

That’s pretty cool to hear. Have you looked at the Klipper CNC fork? I’ve only peaked at it a few weeks ago for a short bit.

Sorry it took me a bit to get back to this. After I installed the laser on the MPCNC I decided that the foot print was too big and the cutting area too small for a laser. So I built a dedicated laser that I am also running on Klipper.

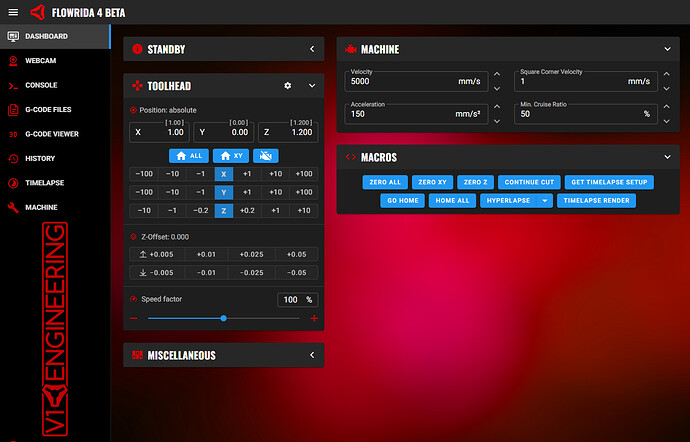

Right now until I find a better option, I am using LaserWeb. It allows you to set the Gcode for your machine.

I have also used Fusion and run a few things that way. The nice thing about Klipper is that I can change the Klipper Config to match the output of the program I am using. So, if the program only puts out G01 commands, not G1 commands, I just change the Macro from G1 to G01.

If there are any extra G/M commands that my machine does not use, I just make a quick macro to send a message to the RELP/Console with a “respond” line and have it just say something. I can have it say "I love cutting or “Ignoring that”, or “I just farted”. It does not matter as long as it has something to do in response to that code, it is happy.

I have now converted my second Cricut Expression cutter to Klipper. I am using LaserWeb for that too. The laser output is 0-1, I made a macro to control the PWN of the Knife solenoid so that I can change the pressure on the knife for different products.

Klipper also allows you to add physical buttons to control actions. So, I have a Load and Unload button that triggers a macro so I can load a sheet right at the cutter.

For my Laser and MPCNC I am adding an E-Stop button that triggers an M112 command to shut it down. You can add Jog buttons, Home button, “Zero ALL” button, etc.

This is why after trying GRBL, GRBLHal, and FluidNC, I went back to Klipper and I love it.

Klipper also gives you the freedom to run nearly any 8 bit or 32 bit board out there. Except, oddly, the ESP32 boards. So, many of my machines are running a Mellow Fly D5 board. $11 each from Aliexpress. Up to 5 axis, you supply the drivers. They work with A4988s, or any TMC drives, even external drives like the 5160 Plus.

Sorry for the delay. Been really busy.

So, yes, I do have macros to make this work. They are really easy to set up. Here is a sample from my Cricut Cutter conversion.

[gcode_macro M05]

gcode:

SET_PIN PIN=KNIFE VALUE=0

RESPOND TYPE=command MSG=‘Knife Up’

[gcode_macro M8]

gcode:

SET_PIN PIN=AIR VALUE=1

RESPOND TYPE=command MSG=‘Air On’

For the Orange Pi I am running it on Armbian, my Cricuts are on a NUC running Mint22.

My laser is currently running on a Raspberry Pi (1)B+. Only 2 axis, no input shaper, so it does fine. My other Cricut was on a Pi Zero W. It also did fine, but I am putting it on the NUC as I prefer Ethernet wired over WiFi.

I don’t have my Config posted anywhere yet, but I would be more than happy to share it and help with anyone wanting to try out Klipper on an MPCNC (or other machine)

Keep in mind you don’t need a Raspberry Pi. You MUST have a Host. Your Host can be a Pi, Orange Pi, Banana Pi, Beagle Bone. Lap Top, desk top, Thin Client, SFF, etc. Any old computer type device capable of running Linux can be used. Many old computers far exceed the power and performance of the Raspberry Pi 3, the Gold standard for Klipper.

I have also looked at it, but for me, I prefer being on the main branch of Klipper. I am able to set up Macros to do everything I want. Many of the features in the CNC fork have either been in some way added into the main branch, or are very specific things that I don’t know enough about to care. I am not a machinist, I am a Technician for a large CNC Water Jet company, but I don’t run CNC machines other than for training and diagnosis. Our software is more dedicated than the Gcode you would find on a HAAS or other CNC mill. With that, being a 3D printer guy, Klipper just makes sense.

Do you have your full config for your cricut expression? I was looking around for a klipper conversion for this, as I am tired of using sure cuts a lot 2 from like 10 years ago. Did it require a board upgrade? If it doesn’t, then do you flash the cricut board over USB? This is the only mention I can find anywhere about a cricut, so i’m sorry about all the questions. I am more into 3D printing than paper cutting, so I have a great klipper setup, and I would like to add my expression to that so I can actually use it again.