I’m honestly surprised you didn’t make your printer a crossed gantry design, just to keep with the theme. ![]()

Yeah, I have some CF tubes here that were for that very thing. I decided against it. I really want to see if that changes Ripple/VFA at all. CoreXY is cool, but a cross gantry has a symmetrical axis, dual belts on each side that are all much shorter, and a much lighter core.

This is the reason I built my first MPCNC also. I built it at the school were I taught to cut out foamboard gliders and airplanes. I used a needle cutter. Hundreds of kids built gliders and several built airplanes.

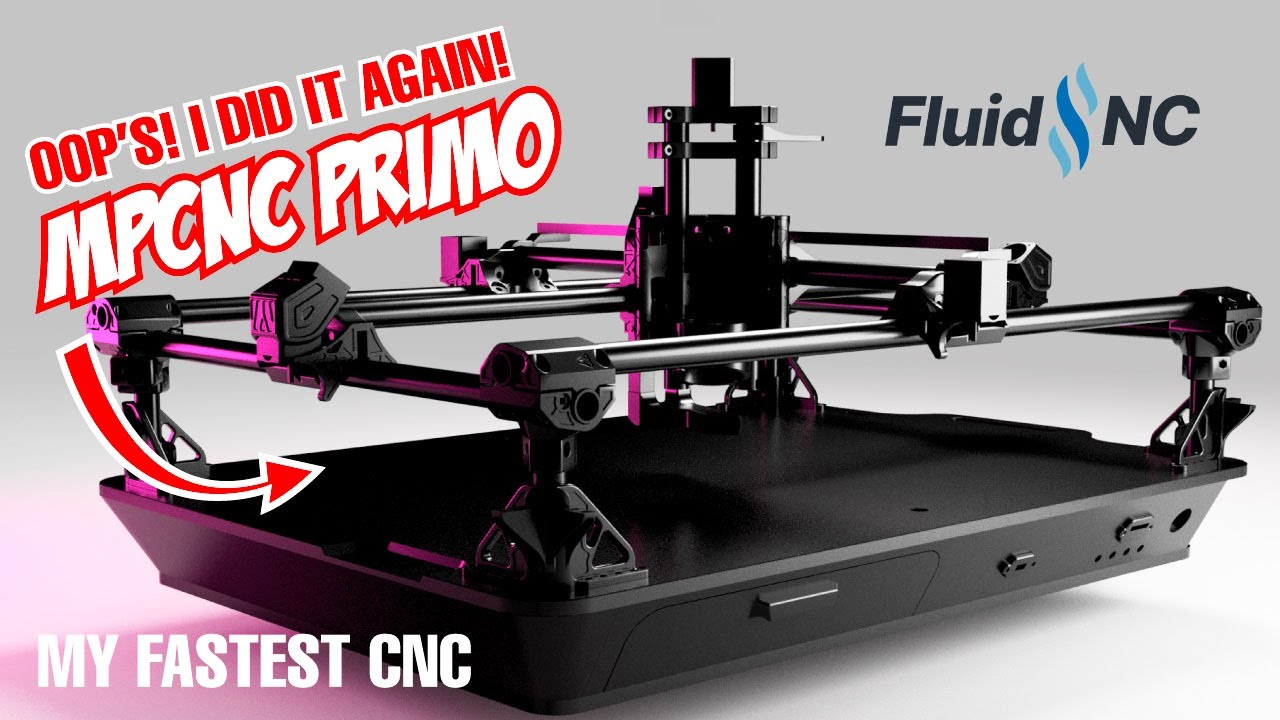

Before I retired in 2021, I built the Primo. I like the price point and the small footprint. I have added a laser to my Primo. I have been cutting lots of 1/8" plywood, etching tumblers and etching glass. I use it etch bottles for a friend of mine to fill with his olive oil that he sells at the Farmer’s Market.

I have 8" legs that I can raise and lower easily to etch the bottles and tumblers.

I would like to see the larger conduit used like the LW4 has now.

Just to throw it out there I chose the MPCNC vs the lowrider only because of the portability of the complete assembly on a small table. It’s a pretty narrow use case and I realize now that I can build a LR4 for about the same cost and have much better attributes overall. I’ll def report back once I’ve built a LR and think it fits the bill for a general CNC Router that’s not some generic Chinese clone.

I like the idea with the hardware enclosure, in special I like how this guy did it, in special the table

This!

Maybe another question to ask is What component or part do you think needs to be changed out? As in, do you currently think there is a weak link?

https://shariffdmc.com/product/dmc2-mini-cnc/, we got to meet these guys at Open Sauce this last year. This machine for $2500 would be very hard to beat in terms of metal milling so the pricing cap/goal is easily set here.

As an engineer I like to tackle problems by starting with any concrete constraints I can without limiting myself in any way unnecessarily.

I think you’re onto something. I just completed a LR4 build, now my mpcnc is in the corner collecting dust. It would be great to have a smaller scale machine that is more rigid and could mill metal. I was also thinking about attaching the mpcnc to my wood lathe.

So it is looking like,

- We take away the metal part and go for light inexpensive, fast. So like the ideal school project build. Mill for wood, plastic, composite, or laser, drag knife?

- Or a extremely competitively priced metal mill, that obviously can do it all in a smaller volume.

This is what I’m personally most interested in.

You could cook up a Mostly Machined CNC project that you can make with your existing LR3/4/MPCNC to fulfill the second one.

Maybe you just defined for yourself the next two products that V1 might work on.

As you note, schools would love the former.

Anyone already proficient with and up against the limits of a LowRider will want the latter.

- MPCNC Next Gen: Quick build, affordable, well packaged, modest footprint, modular, multi-tool for newbies.

- V1 Mill - Max utility for best build price. Rigid enough to do metal work?

Personally, I am a fan of the second one.

As a teacher: I’d really love the first one. What a grand idea. ![]()

Would it be possible to make it one or the other depending on how it is assembled?

Easier to pick one and go from there.

I just wanted to call out how well this summarizes things. Well said!

![]()

This. Assuming we mean more than just the flat aluminum that the LR3/4 can do already. Something that could do thicker aluminum and steel would be REAL nice!

I agree. I think these are two different machines. The MPCNC is the gateway, so probably deserves your attention first. It’s already so refined, I’m very interested in how the ideas come to life.

I also think there would be excitement for a V1 Mill. Perhaps this could even be intended to be built with parts milled with an LR4. I think you’d have a little to work with as far as it wouldn’t have to be your low cost machine, it could be competitive with (under) similar machines from others, but based on the Jackpot and other V1E infrastructure like the forums. But like I said, different machine.

I’m excited to see how many people like the idea of a mill for metal!

![]()

![]()

I guess we don’t need to make M3DP parts though. We need a project to use the mill.