As mentioned in my original Primo Build thread I had a complaint from the neighbours about the noise, so I decided to try my hand at a soundproofing box for my Primo.

I’m getting close to being able to test and refine now, but I wanted to share some of the in-progress shots along the way.

For a stand I went down to Bunnings (our local big box hardware store) and bought a bunch of 900mm 90x45mm pine shorts. I created a basic cube with uprights reinforced by double pine shorts in an L. It was based around this design https://www.youtube.com/watch?v=WG-6897GTx4 that I used for my table saw stand - super simple for carpentry noobs like me and reasonably stable.

Because of the dimensions I added reinforced diagonal braces on 3 sides using wire rope and turnbuckles to tighten. This meant effectively zero lateral movement, which I wanted as the box itself would end up being pretty heavy.

I added castors that I bought in 4 packs from Amazon to move it around.

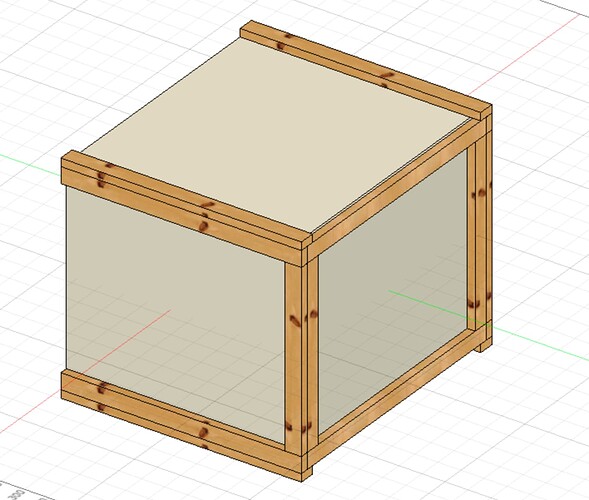

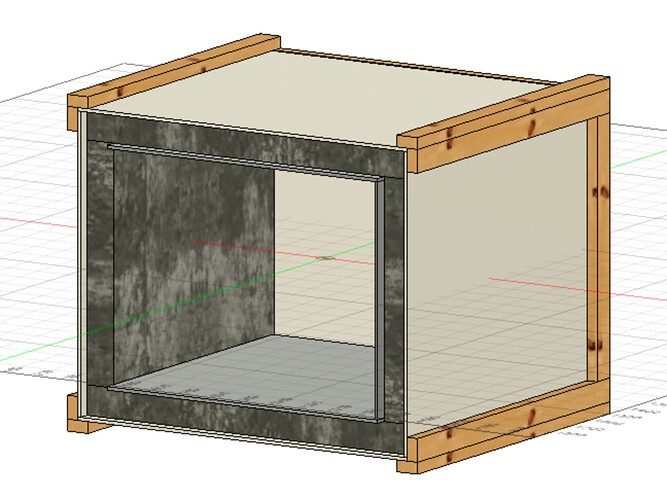

My soundproof box design was created in fusion 360. I build a parameterised interior cube the size of my primo base (with some extra space in each dimension). Then I added a layer of gyprock (plasterboard), rockwool soundchek insulation, waterproof gyprock, then an outer wooden frame.

Back view:

Front view (a bit chopped away so you can see it)

Design-wise I made two mishaps. One was that there was no interior framing, so the gyprock wasn’t mounted to anything. I remedied this by making two additional square interior frames one at the very rear and one in the middle.

Here’s a progress shot showing the base constructed and outer portions of the box:

You can see the wire bracing on the right bottom, there are 2 more sets of that on the back and left.

The base is being used to store my wood pile at the moment, I’ve yet to find a spot for that ![]()

In this shot I have the bottom outer gyprock, and ceiling outer gyprock. I didn’t have an extra pair of hands so I used the roof beam and some tie down straps to macguyver up a winch to get the roof gyprock in place.

In this shot you can see my inner frames being installed. I ended up using L Brackets and screwing them through to the outside frame at the top and the bottom.

Here’s the full outer shell done, 3 inner frames, and all the rockwool insulation. This is where mistake #2 became apparent. I’d tried to keep the amount of outer framing to a minimum, but realised the front top I had no cross member. This resulted in the outer frame bowing out, so I remedied with some extra scrap wood, and required some fairly hardcore adjustments with ratchet straps to get it aligned.

Here’s my dog.

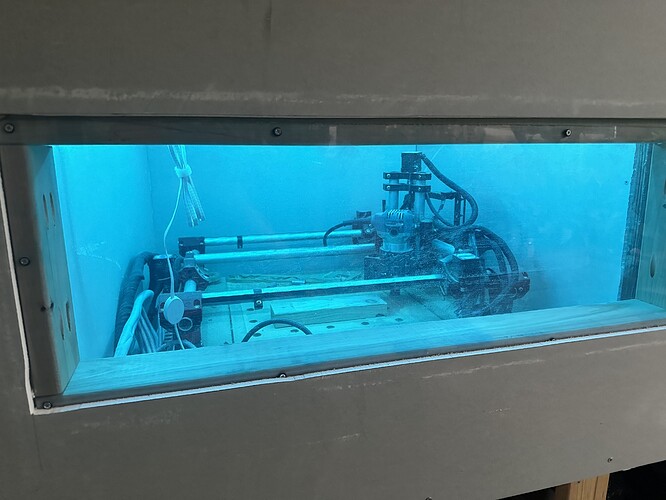

Here’s the full interior done, and the Primo ready to go in. I ran the Primo cabling through a hole in the outer gyprock, along the left bottom insulation then into the inside of the cabinet bottom left corner.

For the door, it was very much a ‘wing it’ at this point. I knew I wanted the same design, so gyprock, insulation and gyprock. I wanted a window, and I had originally planned to open left to right.

I bought some clear acrylic for the window (about 900mm x 600mm) and sliced it in half longways. Then I measured up an interior frame to hold that window and mounted that inside the door frame.

Light bulb moment was to make the door open vertically, with some nice gas lifters.

Heres a shot of the door, primo in place, window in place, inner gyprock in place, and my ikea lights. You can only see the reflection unfortunately, but its in there and the circle of lights are inside the box.

Gas struts installed ![]() yeah i did a little strut when they opened too. To get the right pressure (door is pretty damn heavy) took me 3 trips to Bunnings.

yeah i did a little strut when they opened too. To get the right pressure (door is pretty damn heavy) took me 3 trips to Bunnings.

Last pic for now - installing rubber matting to make the door sealed when shut.

Waiting for the glue to dry and then I’m going to see how we are travelling sound-wise. I did a quick test before and wasn’t as happy as I’d liked, so I’m going to test a little more later today and see where we’re at.

Price so far - don’t ask. Like everything, the original numbers I estimated don’t get close once you factor in all the random other stuff I had to buy along the way. I’m probably at or above the base cost of the Primo ![]() Am really hoping I haven’t made an expensive noise amplifier!

Am really hoping I haven’t made an expensive noise amplifier!