The Bauhaus ruler? ![]()

correct, not many in the u.s. anymore. I wish I had my dads!

Never knew the US had them. ![]()

I have one, made out of metal, that belonged to my Grandfather. I’m nearly 71 years old, I have no idea how old this one is, but I remember it when I visited my Grandfather when I was 6!

Well i am 54 so it was quite a while ago! The retractable has always been king!

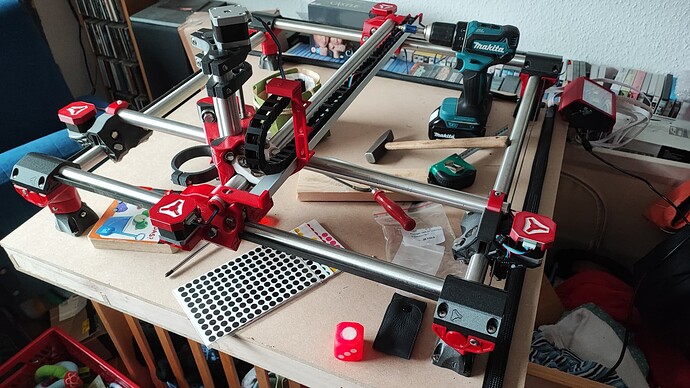

Schneewittchen Reanimated as a drag knife, plotter and later laser.

Oh yes, I want to do that!! RAWR!

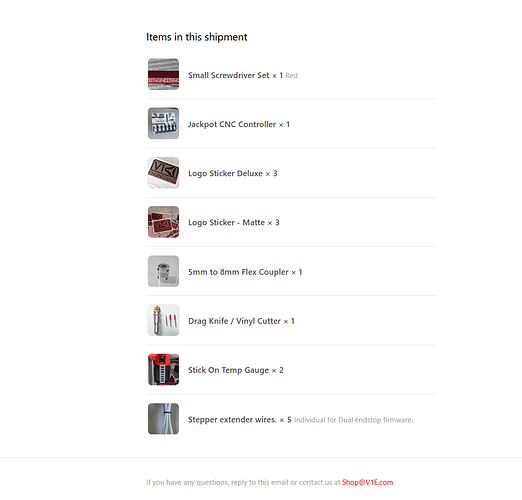

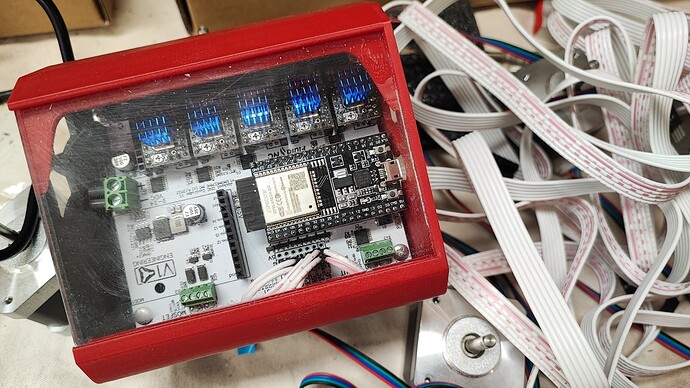

The new insides (not all of it, but most of it). I am not crimping cables again. I can buy a cable for 3€ with everything ready which saves me at least 20 minutes per cable (yes, I am that bad at crimping). I call that a deal. I also still have some 6mm belts from when I bought everything for the Burly, but then the Primo was released, so I am going to use those 6mm belts. They do not need to move much. I also ordered bigger motors for the Froschkönig, so Schneewittchen is getting the old ones back. I am also reducing the size to 50x50cm for more rigidity.

First try at a Jackpot holder. You screw the two holders down and then slide a 5mm piece of hardboard in for the Jackpot to hang onto. Let’s see whether that works.

Updates soonish.

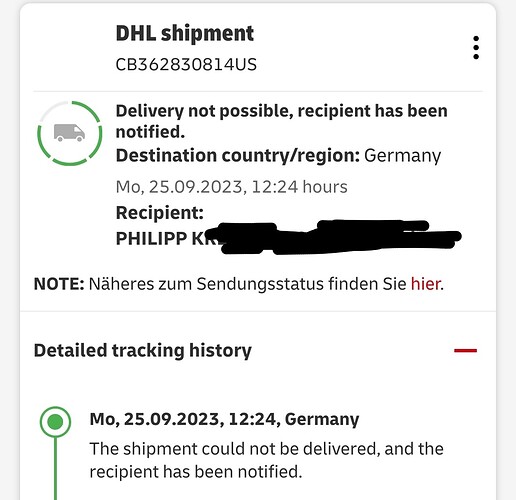

My wife, children and mother in law were at home and he didn’t ring the bell, just left the card, now I have to go pick it up. He was too lazy to do the whole thing with the custom fees, it seems… Grr. Plus, they did bill me 6 Euro handling fees which I opted out of…

Well then…

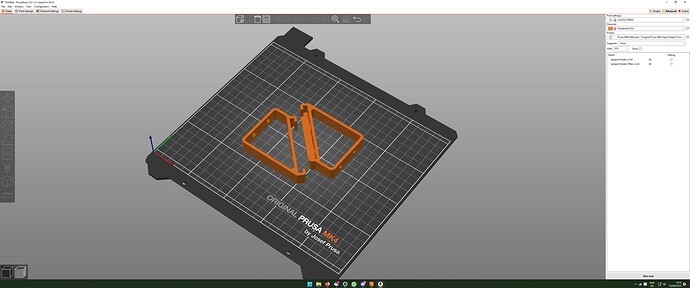

Woop. After paying customs, everything is here now. Thanks so much for the nice message, you even spelled my name right. ![]() It might take a bit until I can actually get it started, but it might be soonish.

It might take a bit until I can actually get it started, but it might be soonish.

Awesome! The messages are always a welcomed touch!!! Glad you got it and now we get to see you put it into action!!!

Dear @vicious1, I feel a bit insulted by the ease of the Jackpot’s setup. It took me a whole 10 minutes to slot the drivers, add the heatsinks, cut my power cord’s cable, crimp the ends, connect them with the readily crimped cables I bought from you, plug in the drivers and connect my mobile to the hotspot it opens. Then all the motors moved. I did not connect the endstops yet, because I didn’t have too much time and could not crimp the wires for the endstops, so homing does not work, but still, what are you thinking?

How can you call this a CNC experience? If it does not take at least four days of crimping, three days of cursing and another five days of looking for the bad crimp or connection, where’s the fun? Do you expect the user to just use your machines? A blatant disregard for the handyman that wants to be taken seriously. What’s next? Are you going to come over and assemble the machine for the users as well? Or at least provide top-notch support if something is not working? Maybe automate your business so you can make even more money? There are dark times ahead…

Okay, sorry. I just felt I had to make some fun about myself and the effort it took to get the Primo running the first time. I am glad I did what I did, I learned quite a lot using external drivers and having the possibility to run more A, but you can be sure as hell that, if we ever create our workshop in the basement of my school, I am going to buy everything ready-made. For a student, the setup of the Jackpot might still be a challenge, but mainly it gives me a more or less hassle-free time.

Here’s the Jackpot, sitting in the rat’s nest of already crimped cables. A dream come true. <3

/edit: I did run into the endstop issue as well, did some tests, results here: New Jackpot Endstop Issue - #16 by Tokoloshe

That clear window looks niiiice.

Soo glad I’ve stuck with the Rambo!! ![]()

Looking good!

Do you feel that the cable-chain is a must have? Also, do you have any plans for the spoilboard?

This one is for plotting only first, if it was for cutting I would have suspended the feet on another board, like I did in the past. I still have them and could add them if needed. ![]()

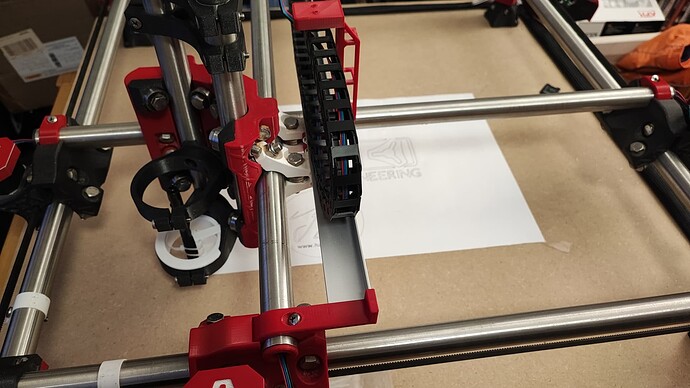

I played around with the tape measure trick on X and Y and made some mounts for it, never had that before. I used to have a drag chain for Z the last time as well, so I did that again, but the tape measure would have worked as well as long as there is the aluminium profile. I also like that nothing attaches to Z directly, just the core.

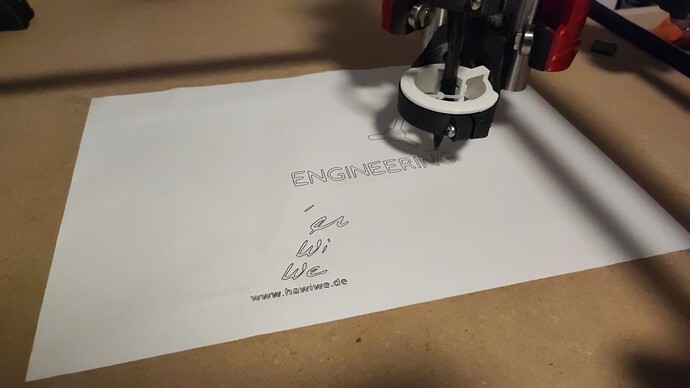

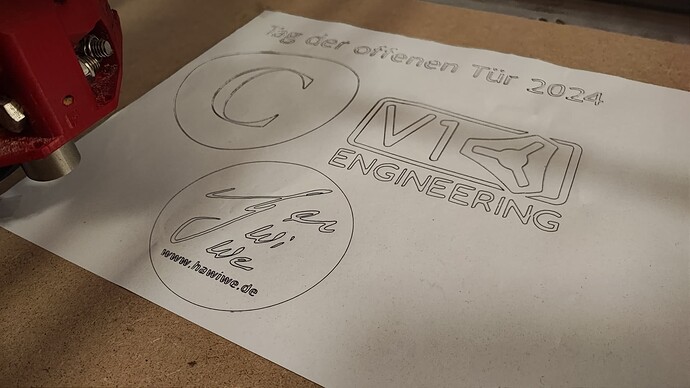

It‘s not a crown, but I think that should count as well. ![]() I did manage to get Fluid going, though I still think it is inferior to Estlcam as a controller (except for autosquaring and the wireless option)…

I did manage to get Fluid going, though I still think it is inferior to Estlcam as a controller (except for autosquaring and the wireless option)… ![]() One thing that amazed me is the speed for the rapids. That thing is fast. And soooo quiet. The motors on my LowRider, powered by TB6600 always make noises, the stepper drivers also make some noise, but the small ones on the Jackpot are just silent. That‘s really neat. Does not really matter if the CNC is working, but for a plotter it is incredibly cool.

One thing that amazed me is the speed for the rapids. That thing is fast. And soooo quiet. The motors on my LowRider, powered by TB6600 always make noises, the stepper drivers also make some noise, but the small ones on the Jackpot are just silent. That‘s really neat. Does not really matter if the CNC is working, but for a plotter it is incredibly cool. ![]()

I hope to change your mind with the UIv3 and some minor tweaks by us. Should be in the next week or two.

That will be really hard. I can’t even move diagonally. ![]()

Diagonal is the killer feature for you? That is not is V3 unless you want to make a macro to move diagonal, which you can very easily do in the webUI with an icon and the length and speed you prefer.

What else?

Have you tried the wireless keybinding to a small wireless keyboard, or laptop key bindings?