I saw your other comment about workspaces. You set all coordinates or just the workspace coordinates with different gcode. Seems you might have just been using the wrong one if you are using workspaces. The UI displays both global and local coordinates as is in both versions.

what is ulv3?

The updated web interface, Version 3.X :: ESP3D Ecosystem

Okay, I might need to look more closely. ![]()

And no, diagonal is not the killer feature, but it’s just there in Estlcam. The toolchange is also a lot easier, setting zero without a touch plate is a breeze. I’d also like for a button where the axis moves smoothly at different speeds and not just the fixed movements that Fluid has. The absolute killer feature is Estlcam remembering the last five starting positions. You home, go to your zero, set it, start the job. Then turn the machine off for days. Start it again, home it again and it automatically sets the last zero you worked with. It’s brilliant, I can cut up projects in lots of small portions without any hassle (like the Aggravation game).

I think you should also try Estlcam for a bit, it’s just easier to work with and feels smoother. I am pretty sure you’d want to switch as well.

In the end it’s just a preference though, I guess. Estlcam is what I started with, your started with printers and Marlin, it’s in your blood. ![]()

I think this quote shows it well:

I don’t know the commands for those things and would need a list, in Estlcam I just know them and vice versa for you. ![]()

We call that workspaces, coordinate systems. Supported Gcodes | Wiki.js we have 6…but it sounds like he might be using some version of grbl under there, so I suspect the buttons and macros are already all set up on his end. On ours we are kinda in limbo switching front ends.

I switched the cncs from marlin to grbl, and building my first klipper printer. I am not opposed to switching, there just needs to be a good reason. I use Estlcam for 99% of all my CAM work, but the selection of boards is the dealbreaker for using estlcam control. There is not a way to add more boards so the Jackpot is running fluid/grbl and marlin.

But this is great. Please check in once and a while and we will see how many of the features we can add buttons for in fluid, see if we can get you happy with using the jackpot. I am confident all the features are there (except surface mapping is estlcam still does that)

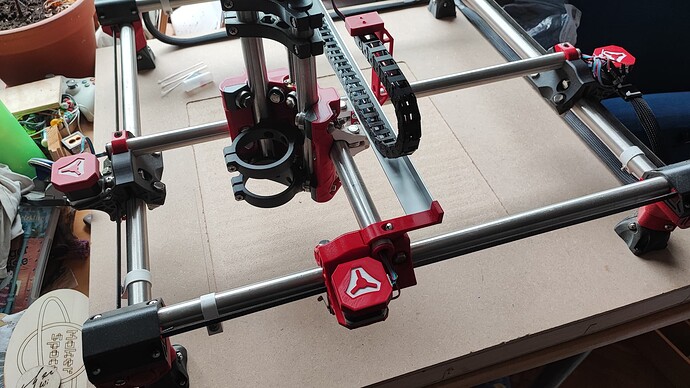

Looks good. What angle is the cable chain? 30, 45 or 55?

This one. ![]()

This one I don’t understand. You need an Arduino Nano or Mega. For the Jackpot you need an ESP32. You showed that you can make good boards, make a better board than the OpenCNCShield 2 with wireless Estlcam and I’d trade it for one of my children. ![]()

I could also buy the expansion for the OpenCNCShield 2 that allows me to switch between boards (Estlcaam/Fluid) on the fly with the press of a button. But it’s not high up on my list.

The selection of boards is also the factor for me not using Estlcam as a controller.

I like Estlcam, but haven’t used it as a controller. Full disclosure, I don’t use a computer as a controller. The only computer in the basement is a Linux laptop that doesn’t have CAM software on it (well, it has LightBurn and PrusaSlicer.) I use it for the MP3DP and for the laser, but the CAM for the LR3 and Primo happen upstairs.

I also use RepRap Firmware, though the laser is going to get set up on a Jackpot and FluidNC “real soon now™” now that I have done a bit of crappy welding, maybe I’ll get to a Z axis for it…

I originally ran the Primo on a Mega, but it choked on the math for G02/G03 moves (arcs) and the machine would stutter in the corners. That was when I went to the Duet board, and I’ve never looked back. I did run the LR2 on an SKR Pro and Marlin, and it handled the computational load fine, I just had another problem with it where it died (while making the LR3 struts and it was still a LR2) so when I built the LR3, it started with the Duet. I have since figured out the problem with the SKR Pro and it’s functional now, but doesn’t have a machine that needs it.

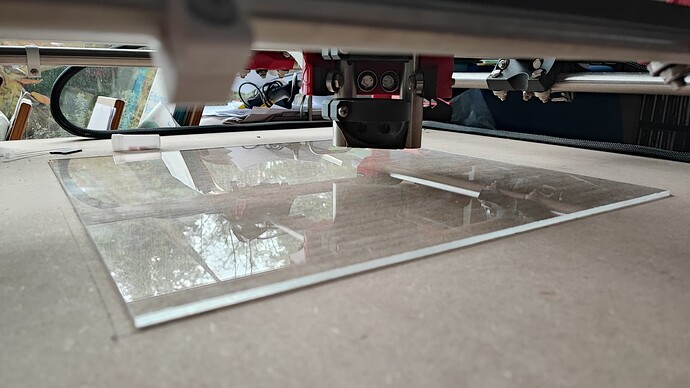

Today’s bad idea: planing the spoilboard in your office because you don’t want to carry the CNC to the shop…

It looks great though. ![]()

Now with acrylic for that extra little bit of flatness: