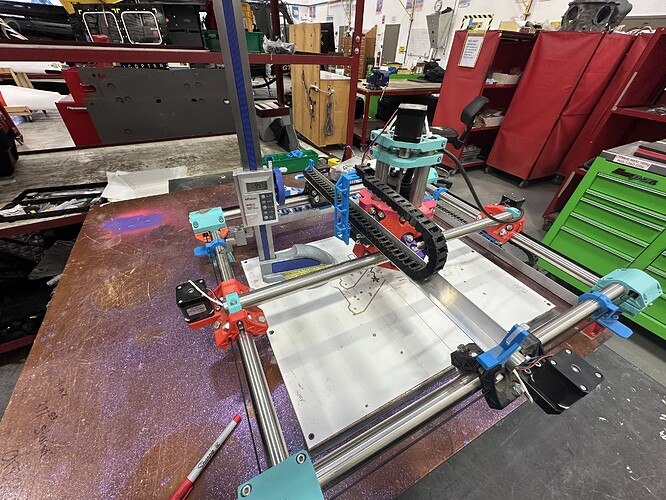

Well I have used my lr3 for quite a bit of foam I brought my mpcnc to work and have been trying my darnedest to brain seed some work colleagues. I think I might have a couple buyers now lol.

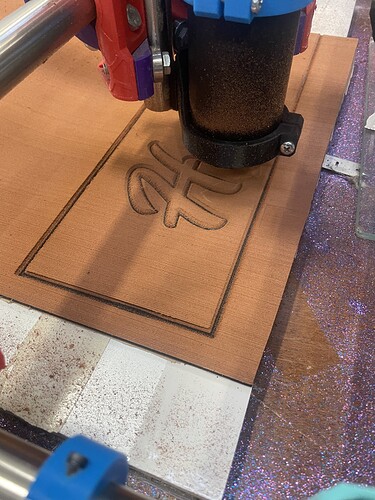

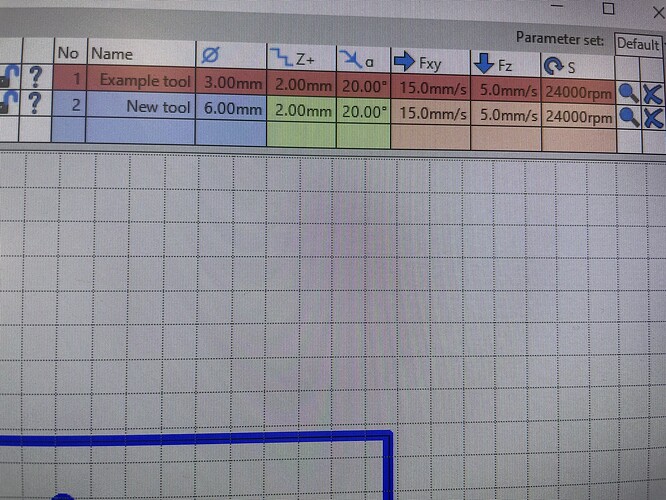

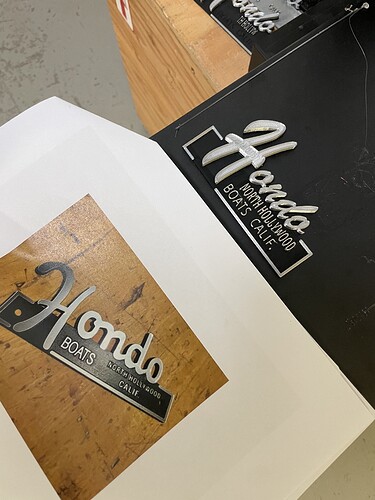

Anyways the project was done using free cad rc. And I downloaded a font to use in freecad. Then I exported as dxf to estlcam. Set my speeds and feeds and figured out my workspace. A nice fellow in here helped me with my start code bc I was inept. Then it was off to the races. I really love the dual end stops bc I am using a cheapo v bit for carving and I want to get my doc just right. So I usually go on the conservative side and go shallow see how it is and then add more. And in this case it has worked well so far. Started with 3 as the top brown color is 2 mm thick. But it wasn’t showing the contrast I wanted well me and the person who’s stomp pad it is ( he is actually our QA guy so I gotta be good I guess lol) so I went to 3.5 doc and I still don’t quite like it. We are going to try 4 mm on the lettering doc I believe I did 4.5 on the border. It’s so nice to be able to let it go and finish, then look and decide if you need more with it perfectly going back to the job. Anyways just a silly project for a buddy at works drag boat he is building. I made the placards for it as well and we wanted the lettering to match so it looks sharp.

The bit is the cheap v 1/4” shank bit that came free with my router.

Looks great! I have a feeling we are going to be seeing a lot more of that two color foam. So many boats and jetskis around here have it now.

I have a bunch in my garage I still need to cut…

never got around to figuring out how to stick it down reliably…or building a vacuum table…

Yes what a pita that slippery backing is.

I pull it off and use butchers paper, or painters paper for automotive. The one side is shiny and sticks to the backing well but can be removed if you don’t leave it for weeks. And the other side is paper and carpet tape seems to stick good to it as well.

I had some I couldn’t remove and I used 3m contact glue and it’s held up well.

Also thanks again for the start code I honestly did search for it in the documents. I hate being that guy lol.

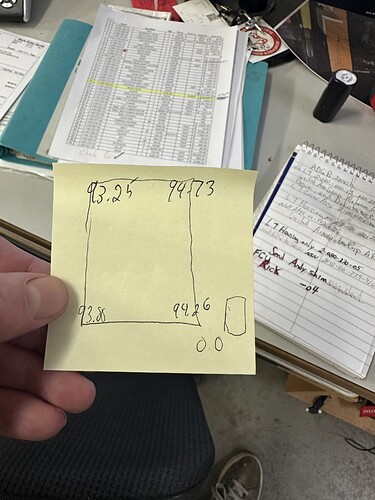

Well it turned out ok. I had a seat to tft interface issue ( operator error) and my gantry wasn’t level and the tape thickness gave me an issue.

It was nice to have it at work so I can pop the digital height gauge on and check for level. It was close but I will get it dialed in now so I can do some decal fun stuff as well.